Steel-concrete beam and column connection joint with weakened section and construction method of steel-concrete beam and column connection joint

A technology for connecting joints and concrete beams and columns, applied in the direction of buildings, building structures, etc., can solve the problems of poor seismic capacity and energy dissipation performance of frame structures, increasing the difficulty of design and construction cost, and poor joint ductility and energy dissipation capacity. , to improve the convenience of construction, the connection is simple and easy to operate, and the effect of solving the poor shear performance and energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

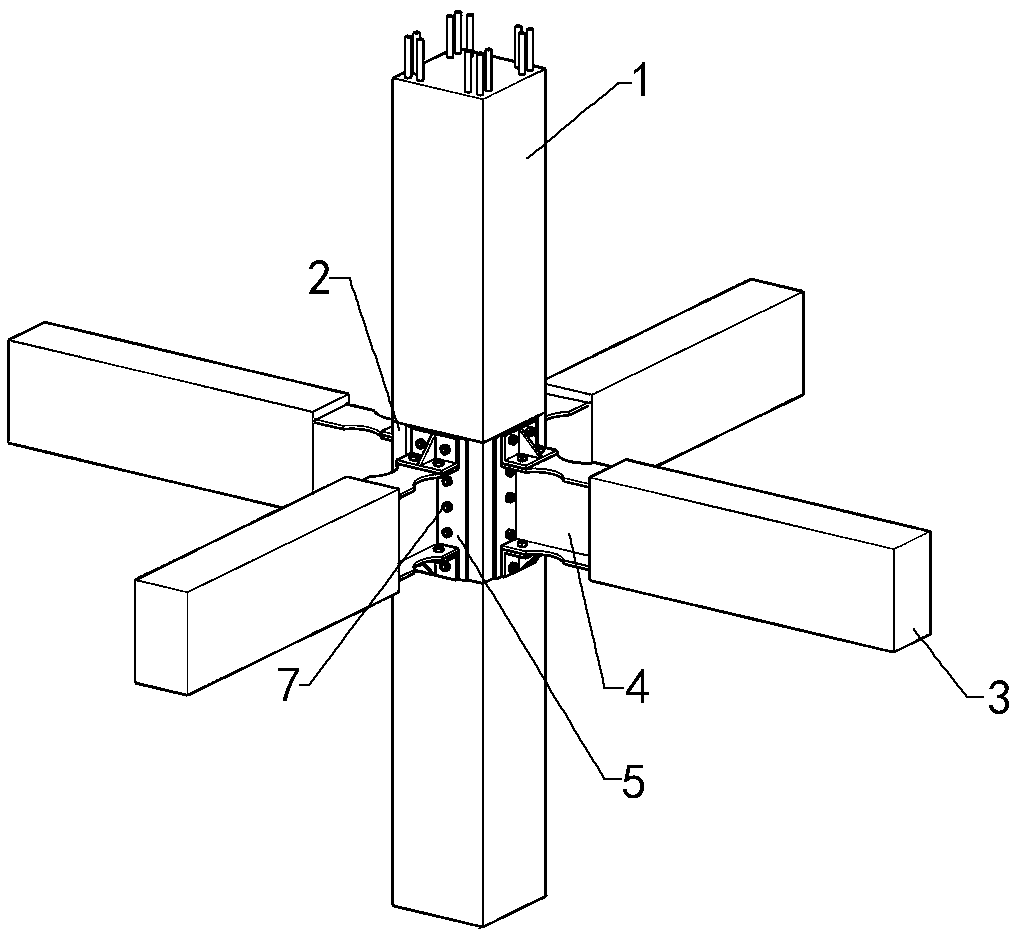

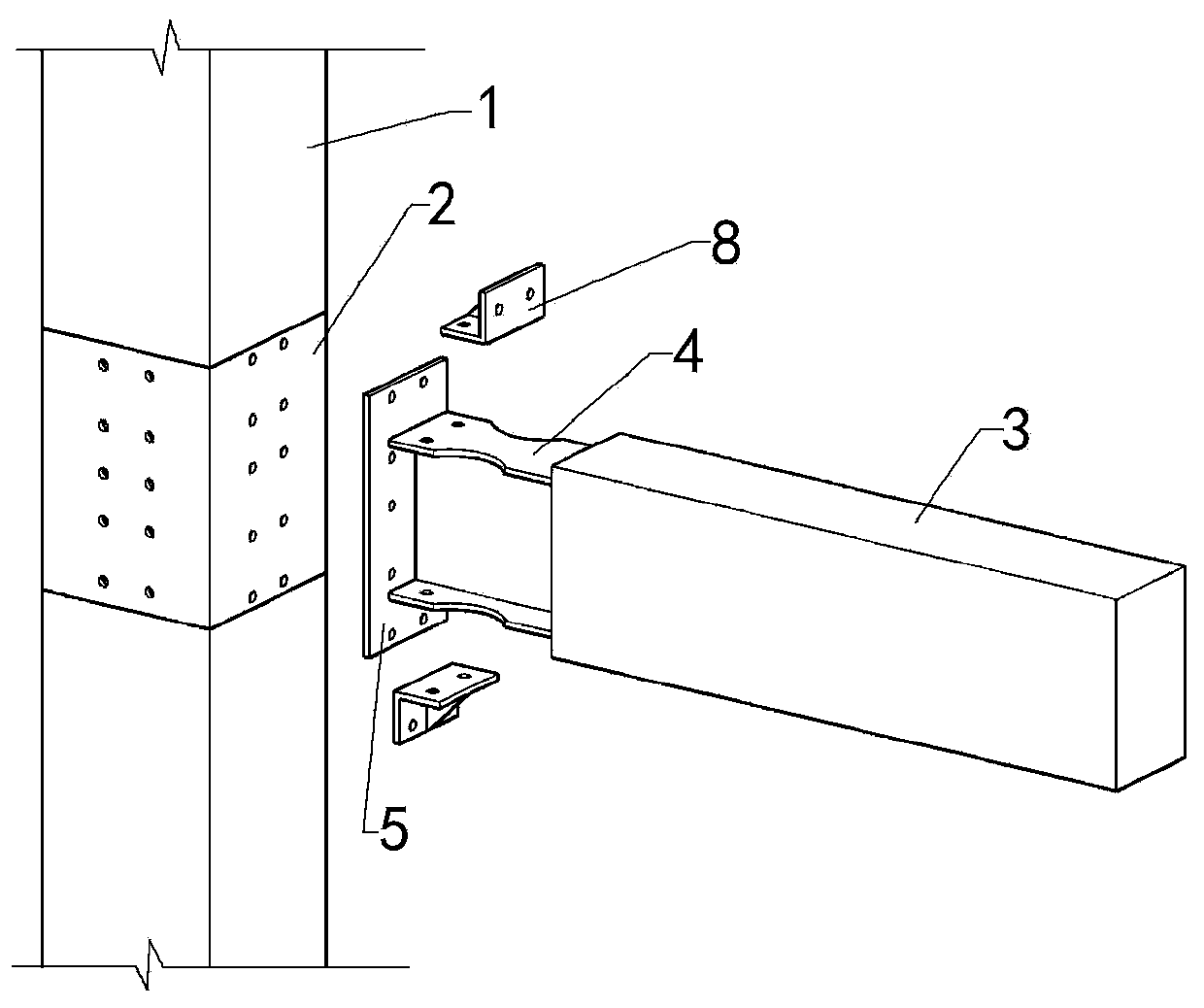

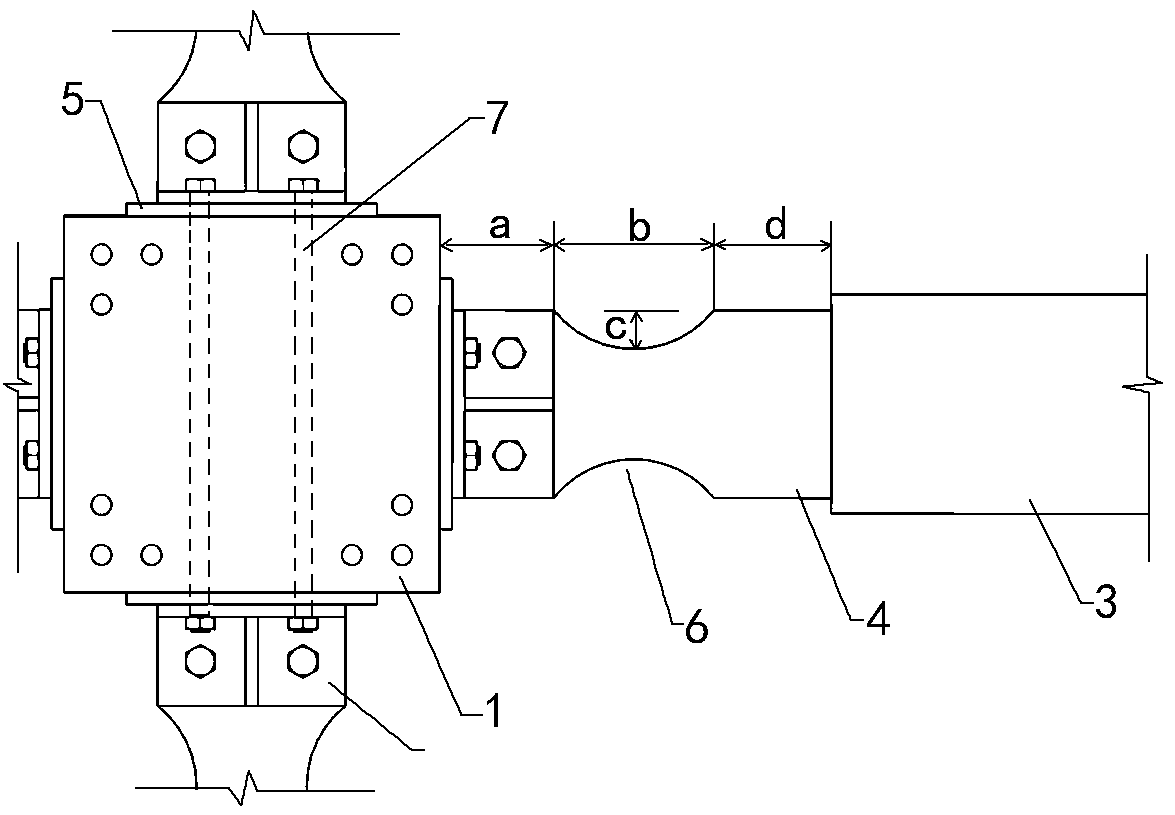

[0051] like Figure 1 to Figure 4 As shown, the steel-concrete beam-column connection node with weakened sections of the present invention includes a concrete column 1 , a cross beam 3 , and a weakened section 4 connecting the cross beam 3 and the concrete column 1 .

[0052] The surface of the concrete column 1 at the connection position with the beam 3 is provided with a steel sleeve 2, and the steel sleeve 2 is symmetrically provided with connecting holes, and connecting holes are reserved in the concrete column 1 between the oppositely arranged connecting holes, two horizontal and vertical. The connection channels in the direction are staggered, and the distance between the upper and lower adjacent connection channels is twice the inner diameter of the connection channel; the steel sleeve 2 is pre-buried and fixed in the concrete during the prefabrication of the concrete column 1 .

[0053] The cross beam 3 is an H-shaped steel beam, a reinforced concrete beam or an H-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com