Liquid level monitoring device for welding strip tin-plating machine

A technology of monitoring device and tinning machine, which is applied in the direction of measuring device, liquid level indicator, lubrication indicating device, etc., and can solve the problems of incomplete tinning and unqualified tinning copper strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

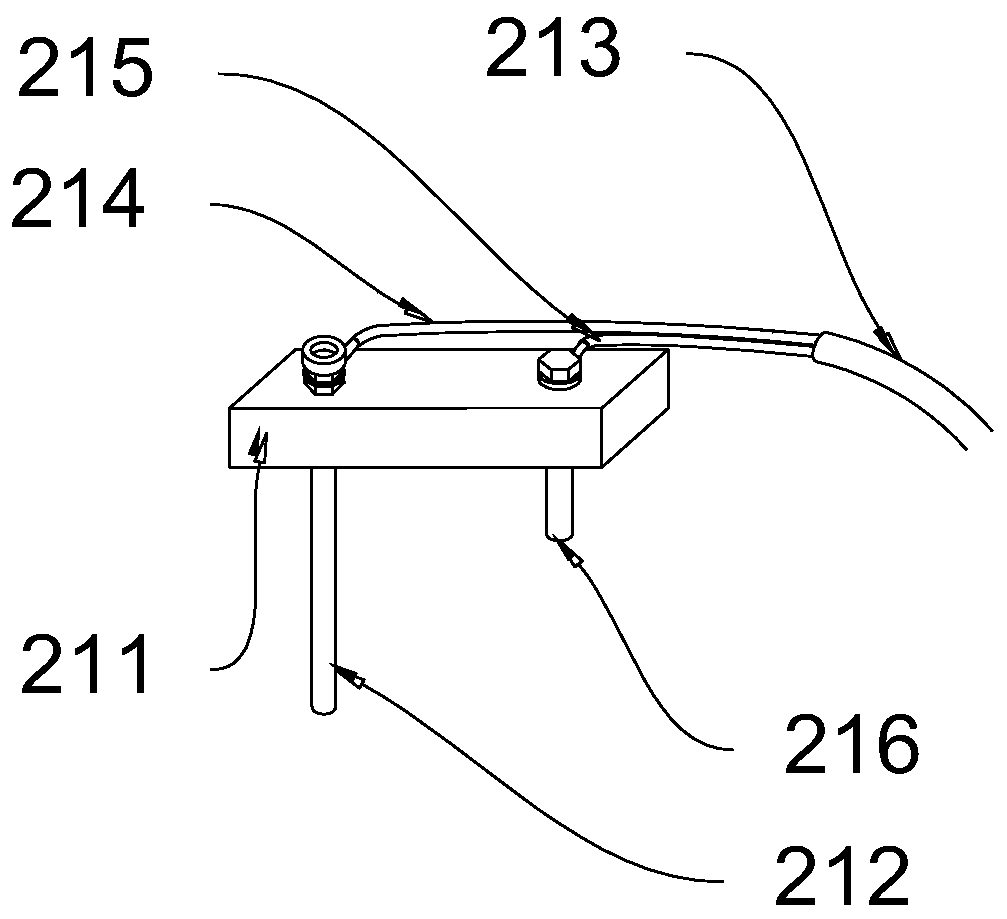

[0015] Such as figure 1 The liquid level monitoring device of a soldering strip tinning machine includes a soldering strip tinning machine 100, and a plurality of tin liquid pools 110 for tinning are arranged on the soldering strip tinning machine 100. Tin machine 100 is provided with tin liquid level monitoring device, and described tin liquid level monitoring device comprises liquid level monitor 210, alarm sound source box 220, alarm flashing light 230 and alarm relay, and described liquid level monitor 210 is arranged on In the tin liquid pool 110, the alarm sound source box 220 and the alarm flashing light 230 are all arranged on the outer surface of the solder strip tinning machine 100, and the liquid level monitor 210, the alarm sound source box 220 and the alarm flashing light 230 are all connected to the alarm. The relays are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com