A magnetic molecular sieve/straw charcoal composite material and its preparation method and application

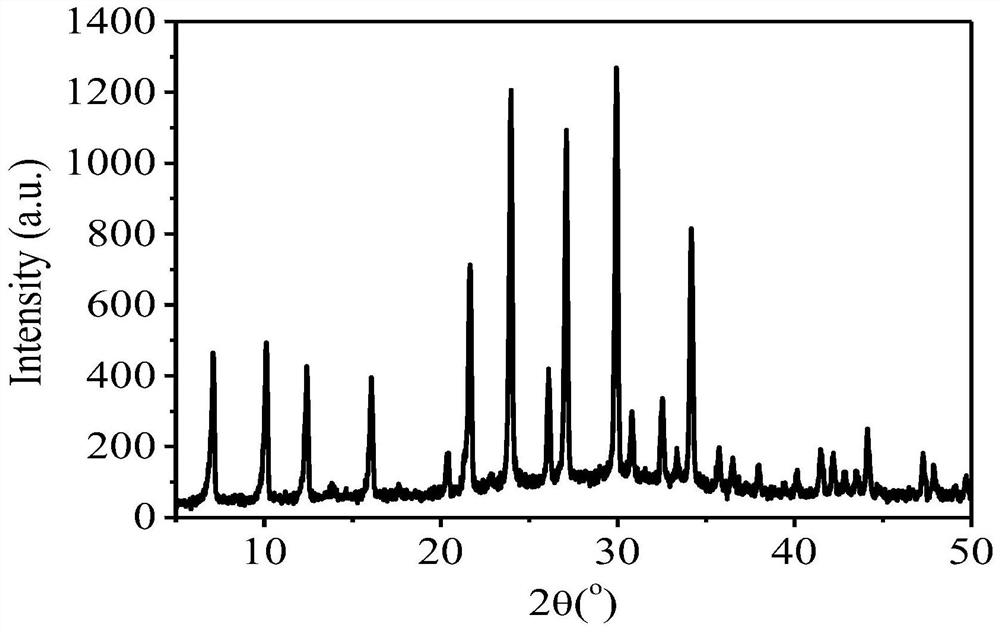

A technology of magnetic molecules and composite materials, applied in chemical instruments and methods, carbon preparation/purification, other chemical processes, etc., can solve the problem of limited adsorption performance of molecular sieves, and achieve improved chemical reaction speed, high specific surface area, and adsorption performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

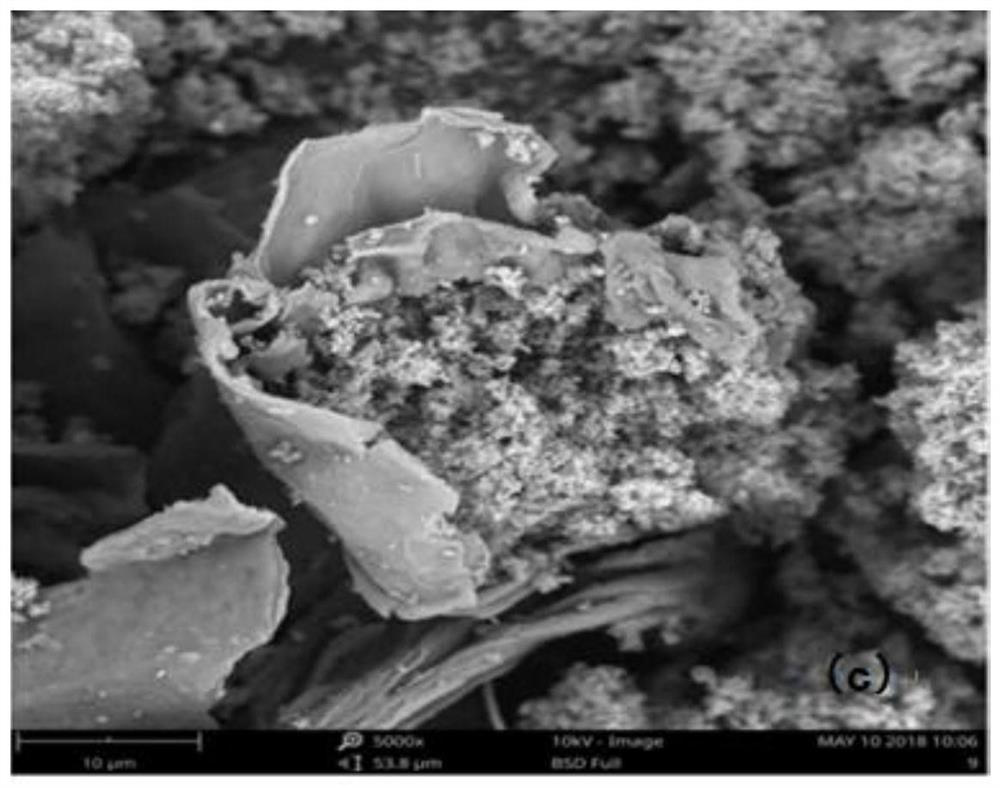

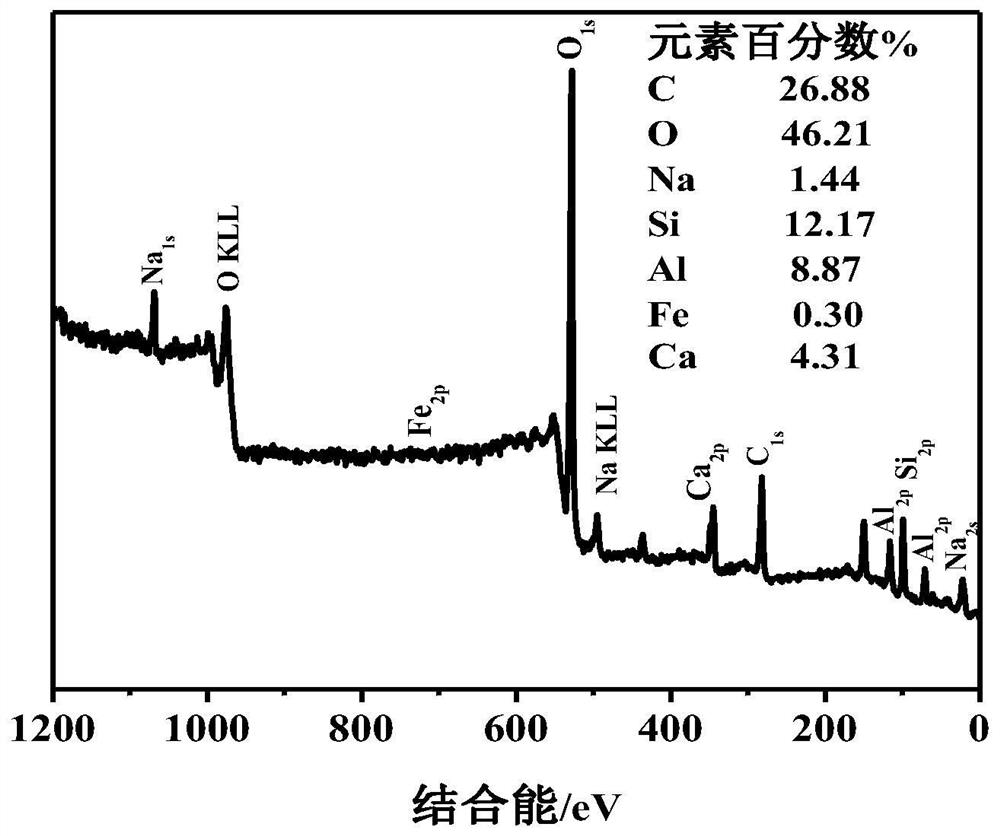

Method used

Image

Examples

Embodiment 1

[0045] The preparation of the magnetic molecular sieve / straw carbon composite material in this embodiment includes the following steps:

[0046] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 25g FeCl per liter of distilled water 2 4H 2 O, add 62.5g FeCl 3 ·6H 2 O; react in 100W ultrasonic wave under the condition of nitrogen protection, and at the same time raise the temperature to 75°C, add NH after constant temperature 3 ·H 2 O (add 125mL NH per liter of distilled water 3 ·H 2 (2) to obtain a solid-liquid mixture after continuing to react for 20min, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, and then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 65 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

Embodiment 2

[0054] The preparation of magnetic molecular sieve / straw charcoal in this embodiment includes the following steps:

[0055] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 18.75g FeCl per liter of distilled water 2 4H 2 O, add 56.25g FeCl 3 ·6H 2 O, under the condition of nitrogen protection, the reaction was carried out in ultrasonic wave, and the temperature was raised to 75 °C at the same time, and NH was added after constant temperature 3 ·H 2 O (add 125mL NH per liter of distilled water 3 ·H 2 (0), continue to react for 20min to obtain a solid-liquid mixture, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 65 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

[0056] Step 2, with sodium silicat...

Embodiment 3

[0062] The preparation of magnetic molecular sieve / straw charcoal in this embodiment includes the following steps:

[0063] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 31.25g FeCl per liter of distilled water 2 4H 2 O, add 68.75g FeCl 3 ·6H 2 O; under the condition of nitrogen protection, the reaction was carried out in ultrasonic wave, and the temperature was raised to 85 °C at the same time, and NH was added after constant temperature 3 ·H 2 O (add 125 mL NH per liter of distilled water 3 ·H 2 (2) to obtain a solid-liquid mixture after continuing to react for 20min, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, and then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 75 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

[0064] Step 2, with so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com