A booster assembly that improves pedal feel

A technology of booster and assembly, applied in the direction of brakes, foot start devices, vehicle parts, etc., can solve the problems of small increase in output hydraulic pressure, unable to shorten braking distance, affecting personal safety, etc., to improve pedal feel and energy. The effect of high transfer efficiency and enlarged feedback area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

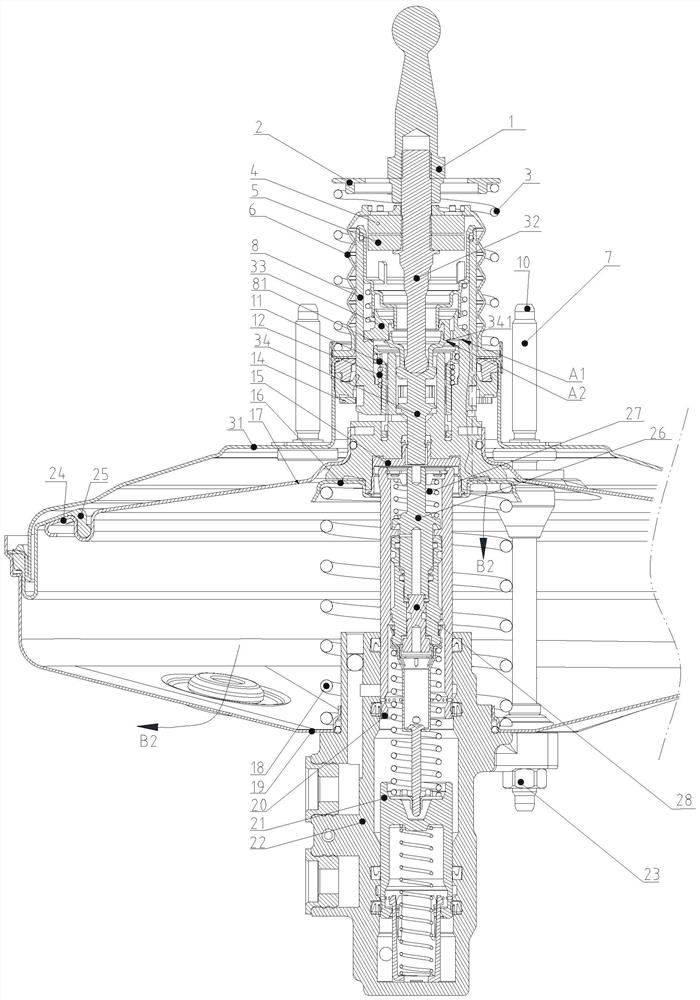

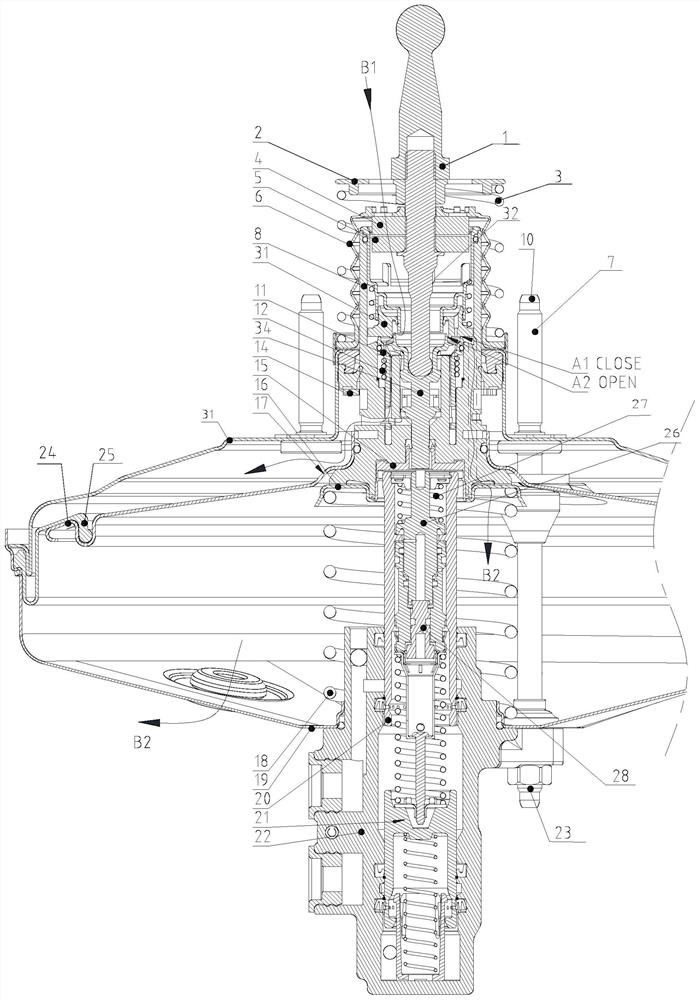

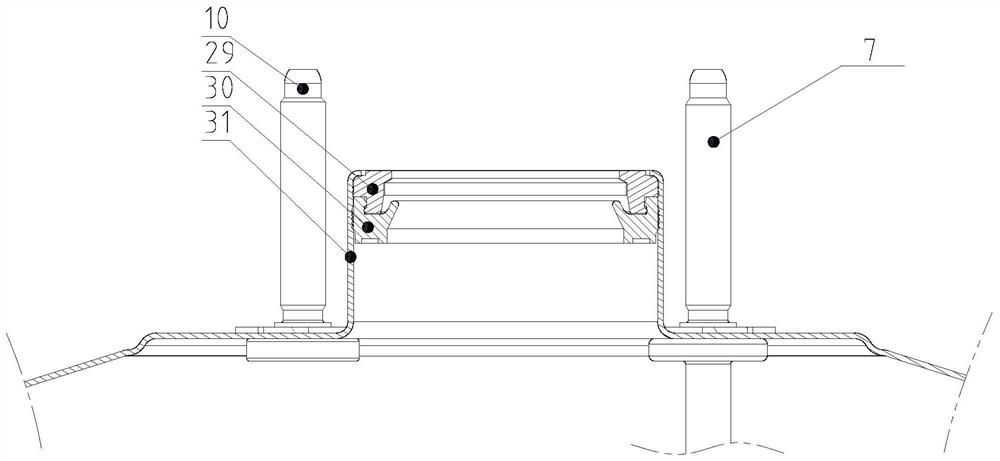

[0034] like Figure 1-4 As shown, the present embodiment provides a booster assembly that can improve pedal feel, including a front shell 19 and a rear shell assembly. The rear shell assembly includes a rear shell 31, a sealing ring 30 and a guide ring 29 to seal and guiding effect, the sealing ring 30 and the guide ring 29 adopt an interference fit with the rear shell 31 to ensure that there is no relative movement. Here, when assembling, it is necessary to apply an appropriate amount of grease to ensure smooth sliding. The front shell 19 and the rear shell 31 are connected to form a shell cavity, and the rear shell 31 is provided with a rear shell screw and a penetration rod 7, the rear shell 31 and the penetration rod 7 are connected by riveting, and the penetration rod 7 is connected to the front shell 19, which can withstand a certain pressure , used to reduce the pressure difference between the front shell 19 and the rear shell 31, also includes:

[0035] The piston hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com