Multi-mandrel full-automatic vertical machining center

A vertical machining center, fully automatic technology, used in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of waste of labor, low efficiency, inability to automatically load and unload materials, etc., to achieve the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

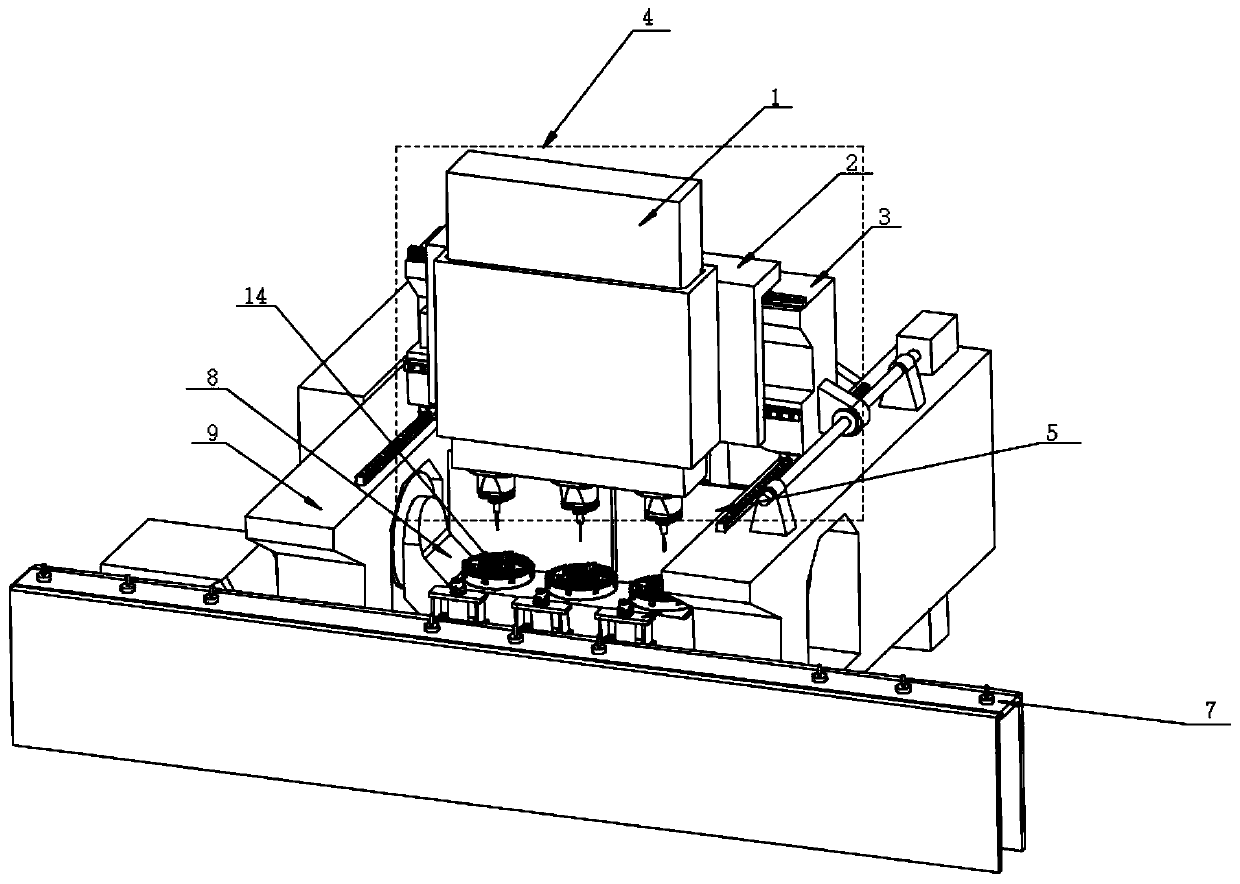

[0031] Embodiment 1: Specifically, as figure 1 As shown, the slide table 3 moves forward, that is, moves towards the direction of the conveyor belt 7, so that the ram 1 reaches the tooling area, and the control end of the machine tool automatically adjusts the position of the saddle 2, so that the main shaft of the ram 1 and the clamping tooling 12 below Keep concentricity. At this time, the position of the ram 1 is set as point A. In this embodiment, three spindle heads 10 are set. At this time, the ram 1 moves downward, driving the three spindle heads 10 to grab the clamping tool 12 below. , and rise to the specified height.

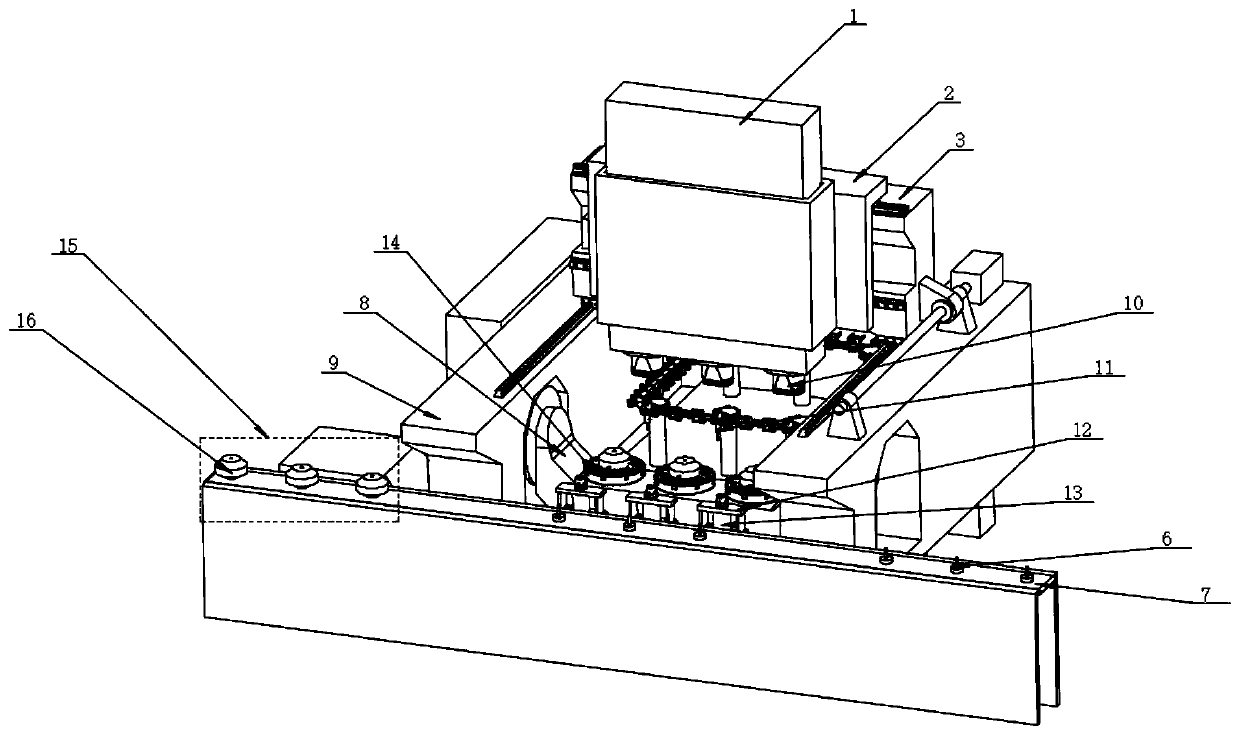

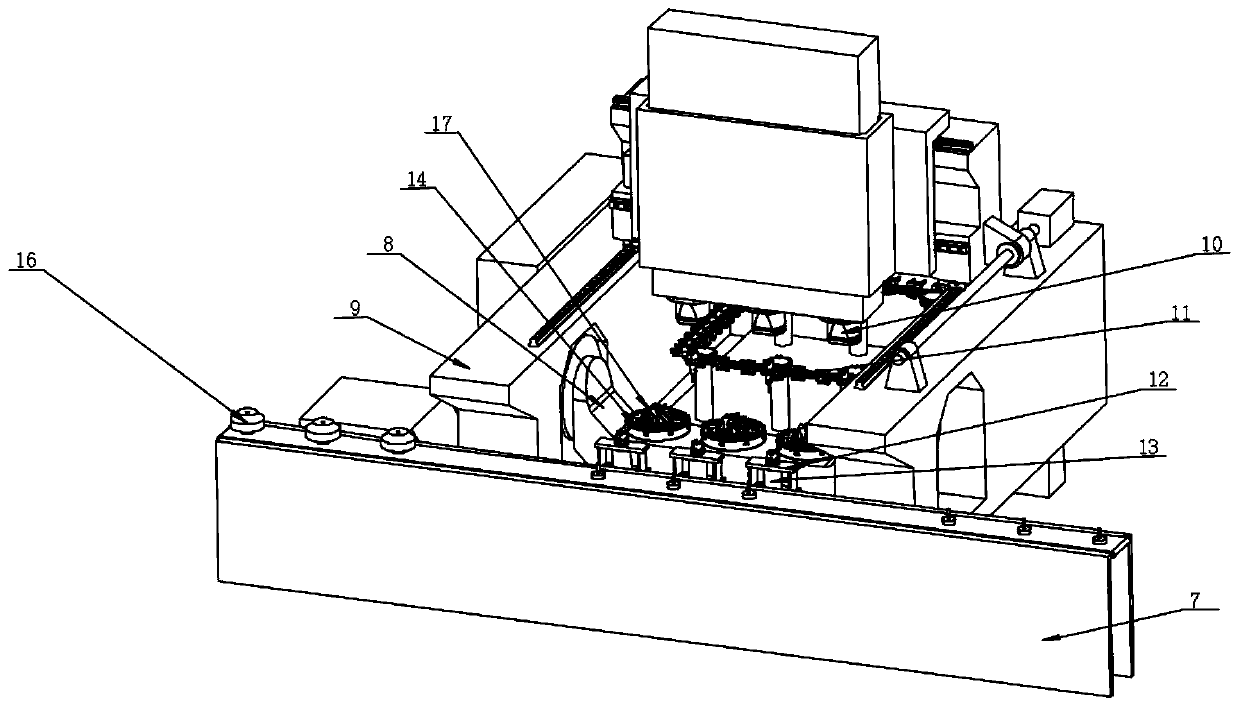

[0032] Such as figure 2 As shown, the slide table 3 continues to move forward, so that the ram 1 reaches the top of the conveyor belt 7, and a plurality of refueling areas 15 are equidistantly arranged on the conveyor belt 7, and the conveyor belt 7 runs intermittently, and the distance of each operation is the same as Adjacent to the distance betwe...

Embodiment 2

[0036] Embodiment 2: On the basis of Embodiment 1, the clamping tool can also be placed on the chain tool holder together with the tool, and the grasping of the clamping tool by the spindle head is similar to that of the clamping tool. The grabbing process of the tool is the same, and will not be repeated here.

[0037] The tool magazine door 5 in the present application is closed during the machining process, which effectively isolates the processing waste and dust outside the tool magazine area to ensure the cleanliness of the tool magazine area; one side of the actuator 4 is provided with the conveyor belt, and the other The workbench and the tool magazine area are arranged on the side, which reduces the working stroke of the spindle head and makes the whole processing process more concise and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com