A welding protection device for the inner wall of a pipeline

A protection device and pipeline technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problem of wasting protective gas, etc., and achieve the effects of avoiding waste, uniform distribution of air flow, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

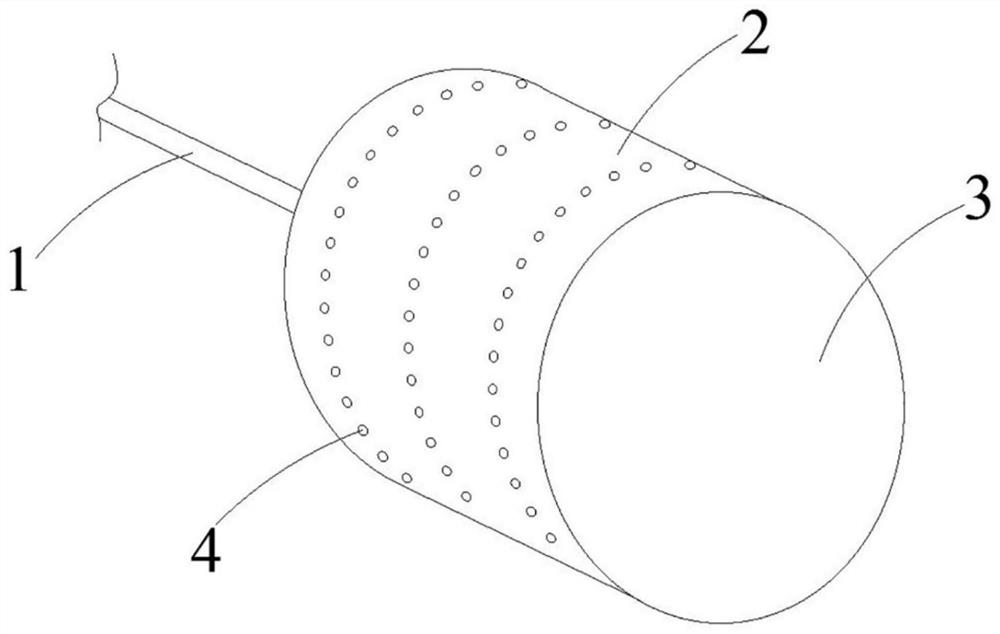

[0027] Such as Figure 1 to Figure 5 As shown, the protection device includes an inflatable tube 1 for transporting protective gas and an air diffuser structure arranged on the inflatable tube 1. The second diffuser tube 2 on the outer peripheral side of the trachea 8, the first diffuser tube 8 is provided with a first diffuser hole 9, the second diffuser tube 2 is provided with a second diffuser hole 4, the first diffuser tube 8 and the second diffuser A diffuser layer 7 is also arranged between the two diffuser pipes 2, and a diffuser channel is arranged in the diffuser layer 7, so that the protective gas can be evenly diffused from the diffuser structure.

[0028] Specifically, the inflatable tube 1 in this embodiment is a flexible tube, specifically a rubber tube, a plastic tube, a fiber tube, etc. The design of the tube enables the protection device to adapt to curved tubes. In other embodiments, the material of the gas tube 1 can also be a material with a small amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com