A screening device for crop processing

A screening device and a technology for crops, applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low screening efficiency and achieve the effects of ensuring vibration effect, improving screening efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

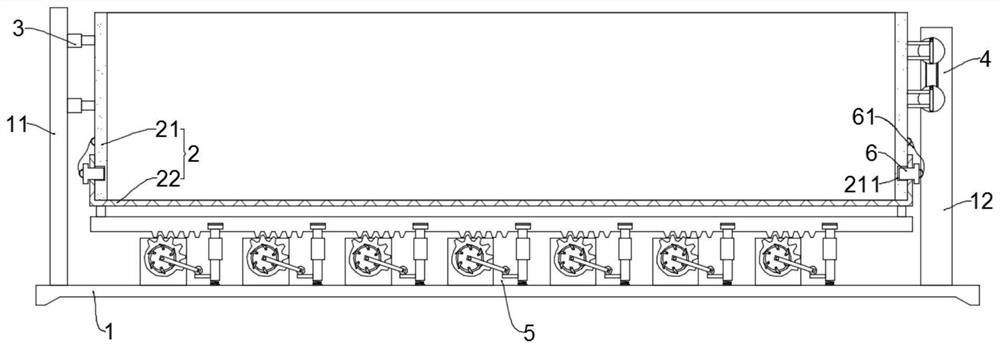

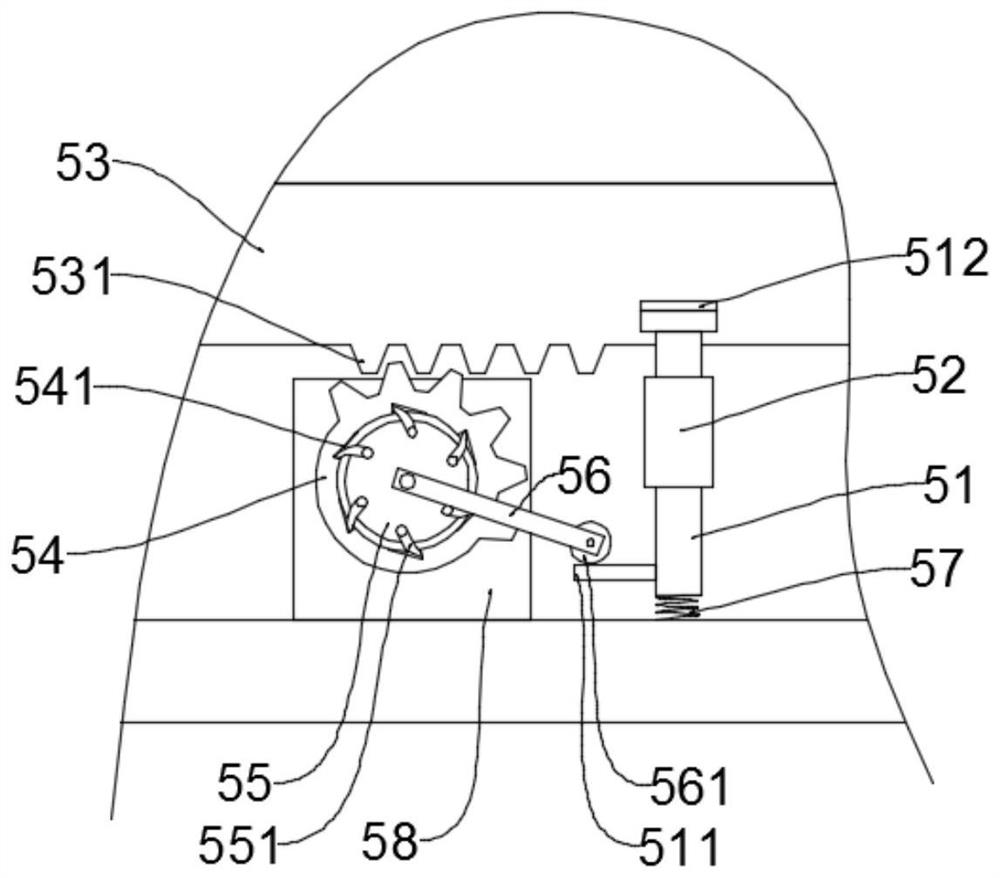

[0023] see Figure 1~4 , in an embodiment of the present invention, a screening device for crop processing, comprising a base 1 and a screen frame 2; the two sides of the top of the base 1 are respectively fixed with a connecting frame 11 and a mounting frame 12, between the connecting frame 11 and the screen frame 2 Connected by telescopic rods 3, a transverse vibrating mechanism 4 is installed on the mounting frame 12. During work, the screen frame 2 is driven to reciprocate left and right by the transverse vibrating mechanism 4.

[0024] Described screen frame 2 comprises the housing 21 of upper and lower both sides opening, and the lower side opening of housing 21 is provided with screen cloth 22; The screen 22 is driven to vibrate vertically, so that the screen 22 can vibrate in multiple directions to improve the screening effect.

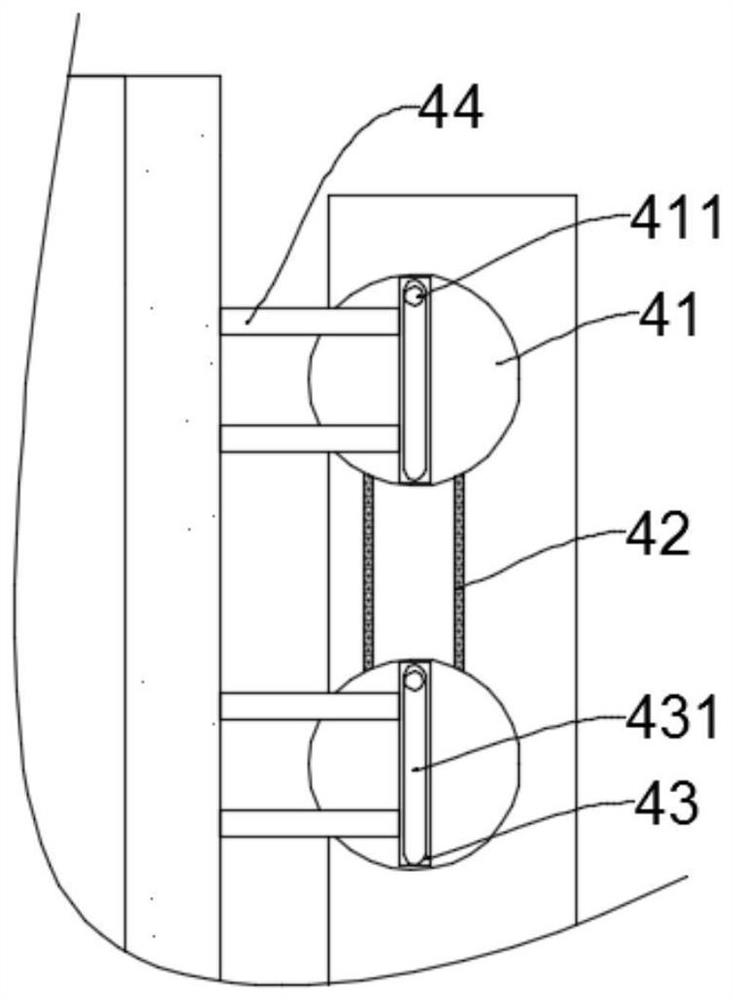

[0025] The specific structure of the lateral vibration mechanism 4 is not limited. In this embodiment, the lateral vibration mechanism 4 inc...

Embodiment 2

[0032] The embodiment of the present invention is optimized on the basis of embodiment 1, specifically:

[0033] The outer wall of the lower opening side of the housing 21 is provided with at least three threaded holes 211 equidistantly arranged in the circumferential direction, and the threaded holes 211 are matched with bolts 6, and the bolts 6 pass through the mesh holes of the screen 22 and the threaded holes 211 connection, so as to fix the screen 22, and also make the screen 22 and the housing 21 detachable, so as to facilitate the replacement of different screens 22 according to technological requirements.

[0034] Further, the bolt 6 is connected to the outer wall of the casing 21 through a connecting rope 61 to avoid loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com