Dreg-juice separator

A technology for slag juice separation and transfer components, which is applied in the field of material processing, and can solve problems such as long production cycle, low efficiency, and increased production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

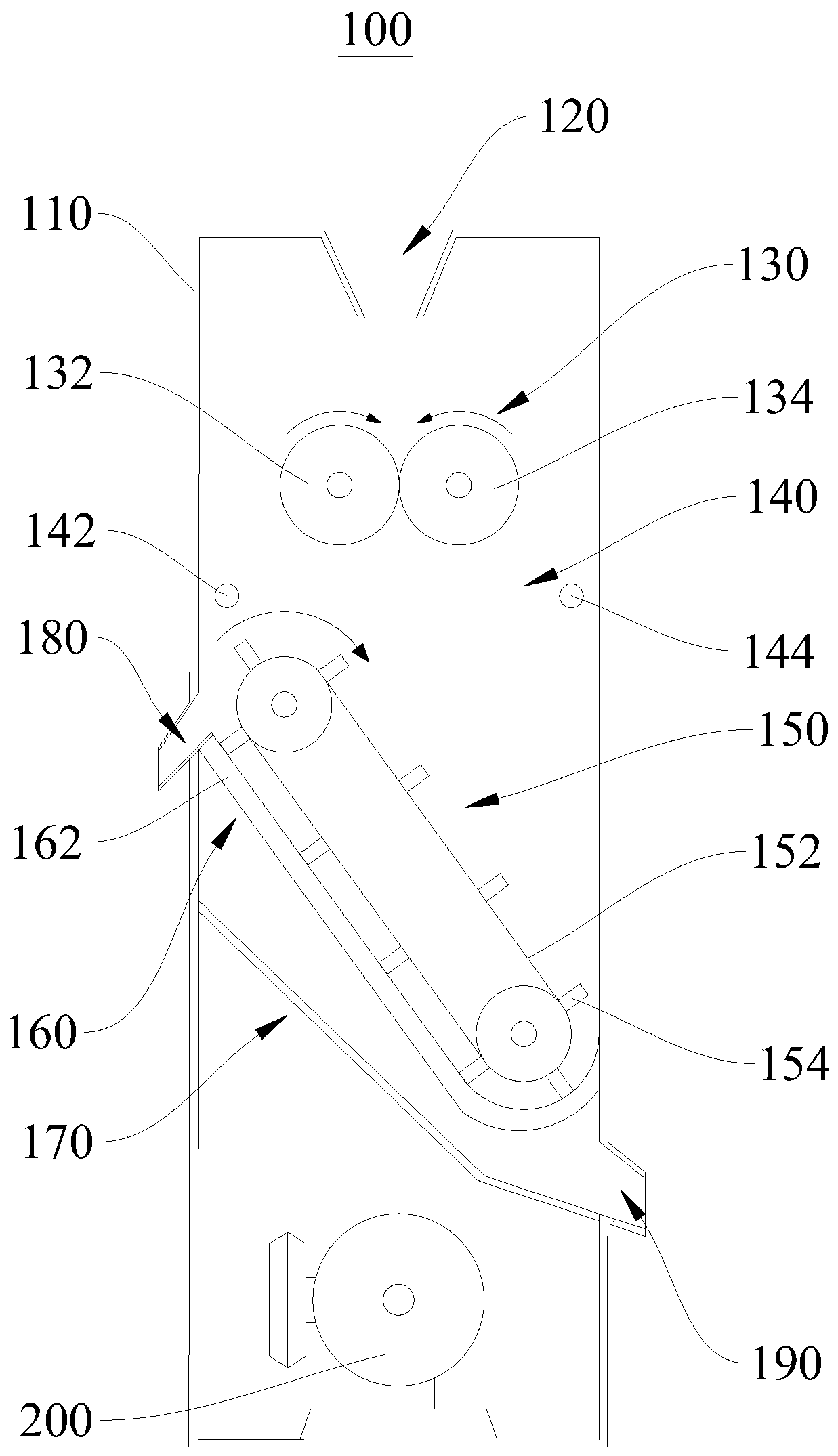

[0029] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the internal structure of the juice separator 100 . This embodiment provides a slag juice separator 100, which can quickly, efficiently and continuously complete the process of separating slag juice.

[0030] At present, because the existing equipment is not effective in filtering and removing slag from the viscous liquid obtained by pressing, the conventional method is to let the viscous liquid obtained after pressing stand for several days, so that the slag will automatically settle, and the production cycle It is longer, the efficiency is lower, and the sterilization equipment is always in working condition during the static period, which indirectly increases the production cost.

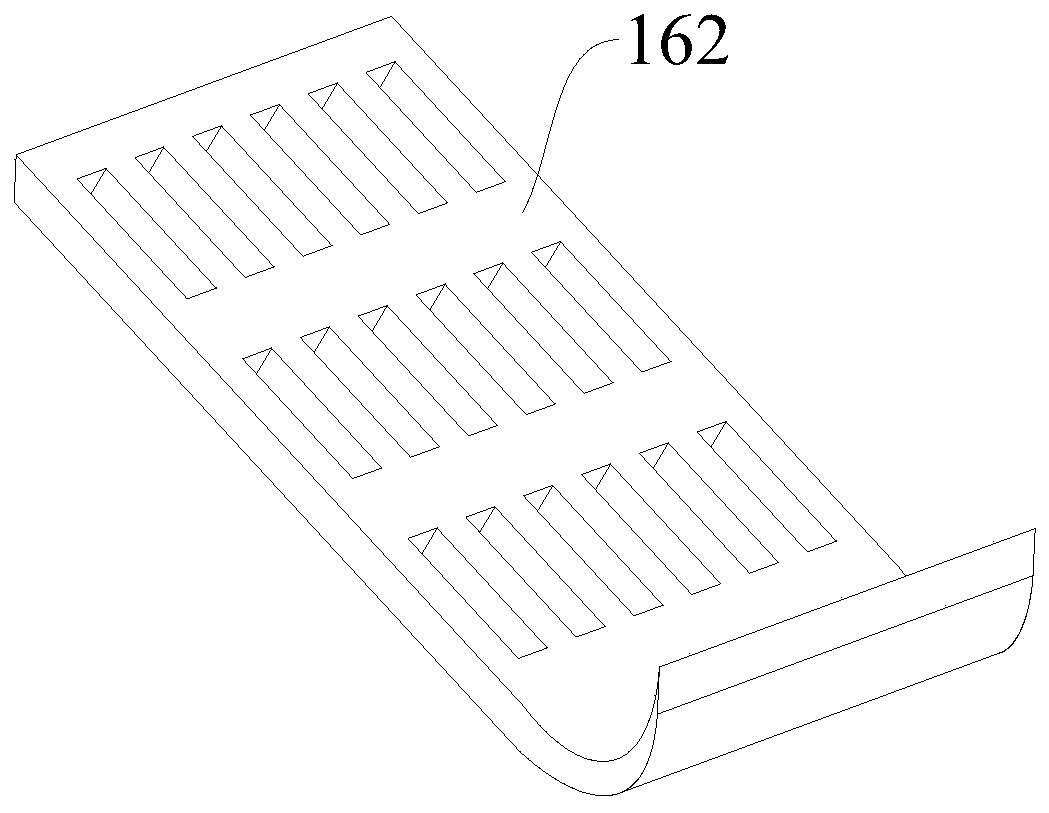

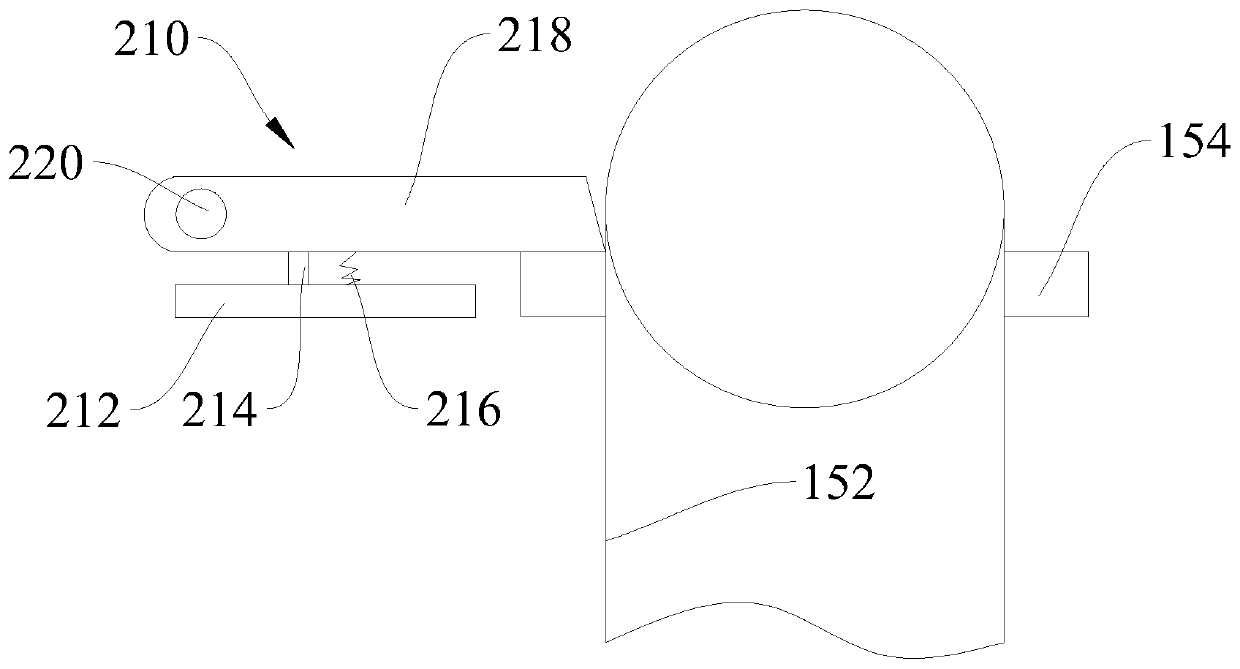

[0031] In this embodiment, taking viscous liquid as an example, the working process of the slag juice separator 100 is explained. The juice separator 100 mainly includes a transmission component 150 and a filter compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com