Pressurization air filter for four-cylinder four-stroke generator

A four-stroke and generator technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problem of cleaning the filter part of the engine without the engine, it is difficult to ensure sufficient fuel combustion in the cylinder, and the service life of the engine air filter is short, etc. to improve fuel economy, reduce emissions and noise, and increase specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

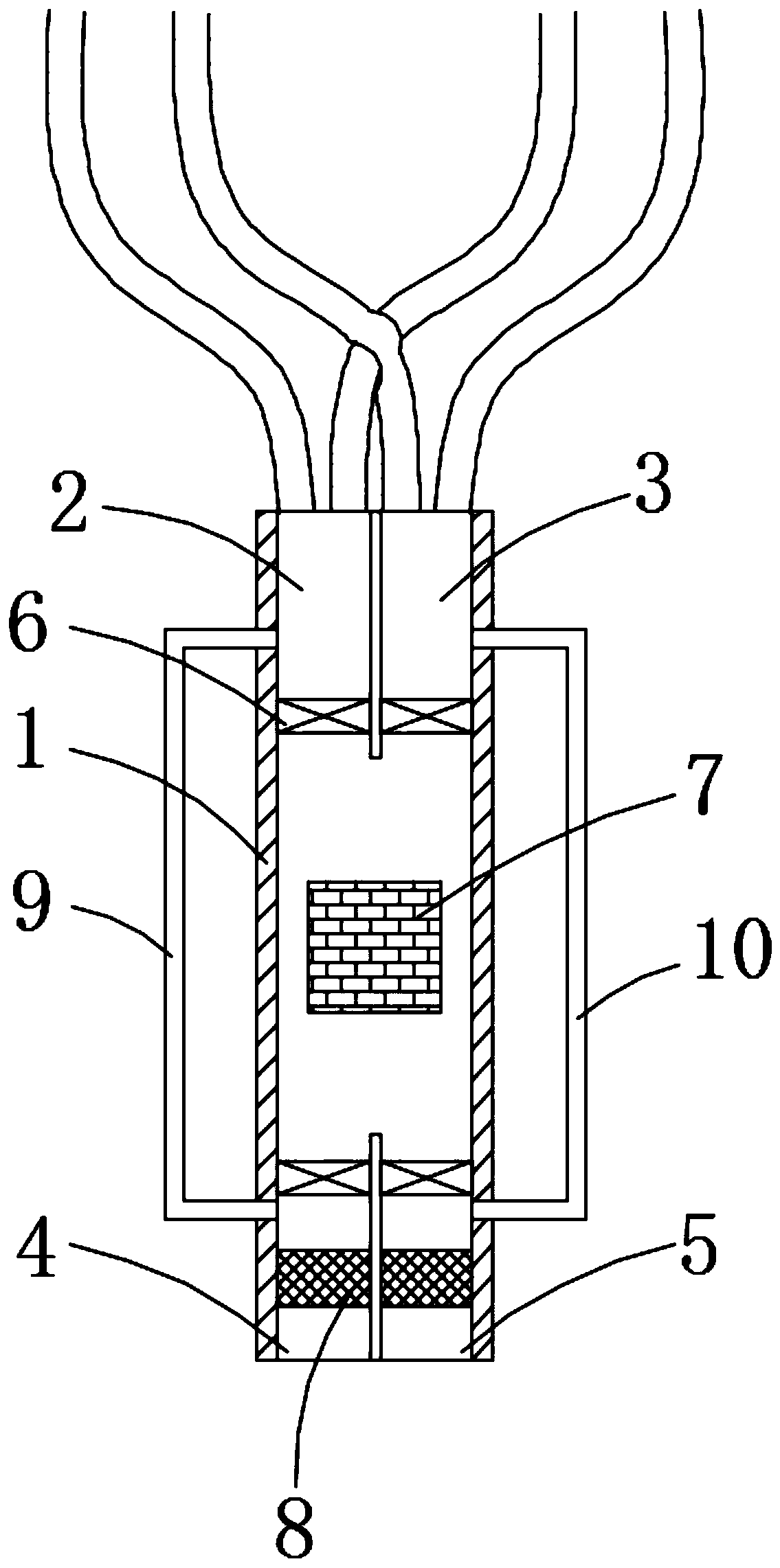

[0014] refer to figure 1 , a pressurized air filter device for a four-cylinder four-stroke generator, including a main pipe 1 whose two ends communicate with the outside world and the engine intake end respectively, and an air pump 7 is fixed in the middle of the main pipe 1, and the main pipe 1 is close to the One side of the engine is divided into the first clean air chamber 2 and the second clean air chamber 3, and the other end of the main pipe 1 is divided into the first air intake chamber 4 and the second air intake chamber 5, the first clean air chamber 2, The second clean air chamber 3, the first air intake chamber 4, and the second air intake chamber 5 are all provided with a valve, and the first clean air chamber 2 and the first air intake chamber 4 are jointly communicated with a first air return pipe 9. The second clean air chamber 3 and the second air inlet chamber 5 communicate with the second air return pipe 10 , and a filter screen 8 is fixed in the first air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com