Dynamic control system for blue light control and application thereof

A blue light and promoter technology, applied in the field of bioengineering, can solve the problems of uneven mass transfer of dissolved oxygen, affecting the growth and accumulation of acetoin in Escherichia coli, and achieve a simple design, few system components, and low strain growth load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

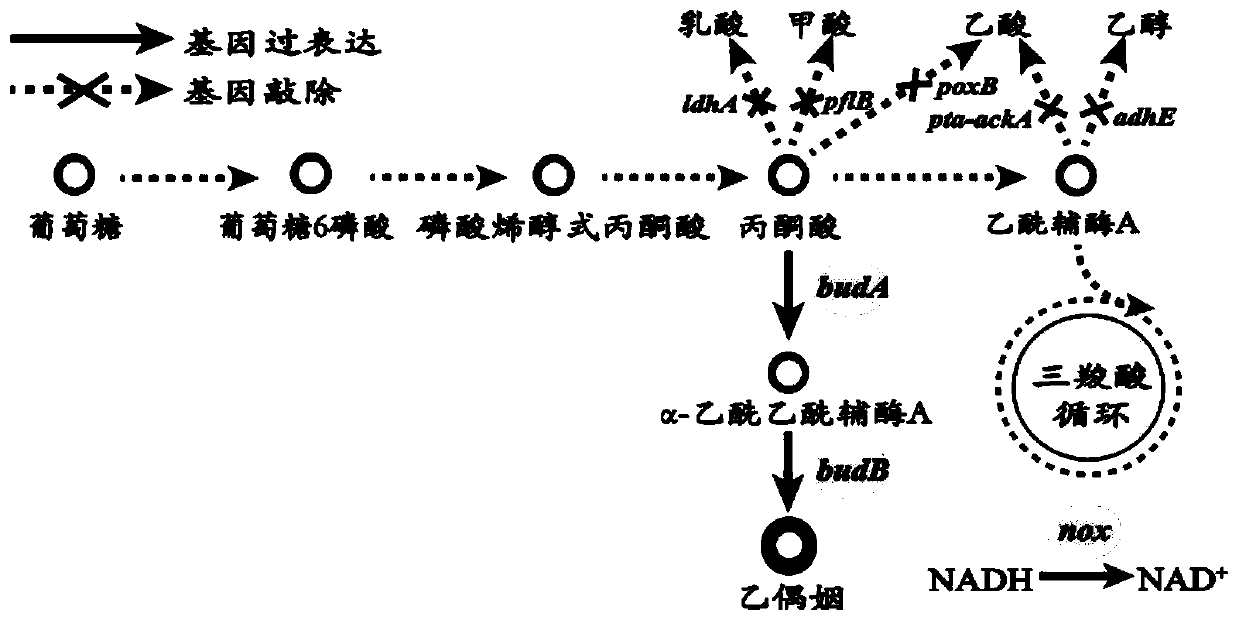

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Evaluation of blue light-activated components under different light intensities and light pulse periods

[0047] Will P Trc -E and pBLind-mKate plasmids were transferred into E.coli F0601 (see: Dong X, Chen X, Qian Y, et al. Metabolic engineering of Escherichia coli W3110 to produce L-malate[J]. Biotechnology&Bioengineering, 2016, 114 (3): 656-664.), obtain engineering strain, place it in LB culture medium, use SpectraMax M3 microplate microplate reader to carry out continuous fluorescence measurement to above-mentioned engineering strain. When the strain is exposed to 450nm blue light, the blue light photosensitive protein EL222 binds to P lux or P J23119 Before the promoter, the expression of fluorescent protein mKate is realized.

[0048] Experiments were carried out under dark or 450nm blue light conditions, and the results were as follows figure 1 As shown, Figure A shows the dose dependence of the light intensity of the blue light system. With the in...

Embodiment 2

[0049] Embodiment 2 dynamic gene circuit introduces the shake flask fermentation performance of acetoin production strain

[0050] Such as image 3 shown in P Trc -E-P J23119 -BudAB-NOX and pBLind-FtsZ-FtsA (see plasmid map figure 2 ) as an expression vector, different dynamic gene circuits were introduced into the E.coli F0601 strain, and a total of 7 engineering strains such as D1-D7 were obtained, and the D1-D2 strains expressed only the expression of P Trc -E-P J23119 -Engineering strains obtained from BudAB-NOX, pBLind-FtsZ-FtsA, D3-D7 engineering strains for the co-expression of P Trc -E-P J23119 -Engineering strains obtained from BudAB-NOX and pBLind-FtsZ-FtsA, D3-D7 respectively represent blue light intensity of 0.2W / cm 2 、0.25W / cm 2 、0.3W / cm 2 、0.4W / cm 2 , Engineering strains at 0.8W / cm.

[0051] Such as Figure 4 with 5 As shown, the strain growth and product synthesis were detected in NBS inorganic salt medium. The shake flask fermentation results show...

Embodiment 3

[0052] Example 3 Fermentation performance of fermenter for introducing acetoin production strain into dynamic gene circuit

[0053] The fermentation performance of the D7 strain was tested in a 5L fermenter. The temperature is constant at 37°C, 500rpm, the initial inoculation amount is controlled at 5%, the ventilation rate is 1vvm, and the fermentation period is 72h. At the end of the fermentation, the accumulation of acetoin reached 63g / L, and the conversion rate reached 0.57g / g glucose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expression | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com