Method for recycling fresh scrapped concrete

A technology of concrete and recycled concrete, which is applied in the field of civil engineering, can solve the problems of lack of recycling of fresh and scrapped concrete, and achieve the effect of super long workability retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

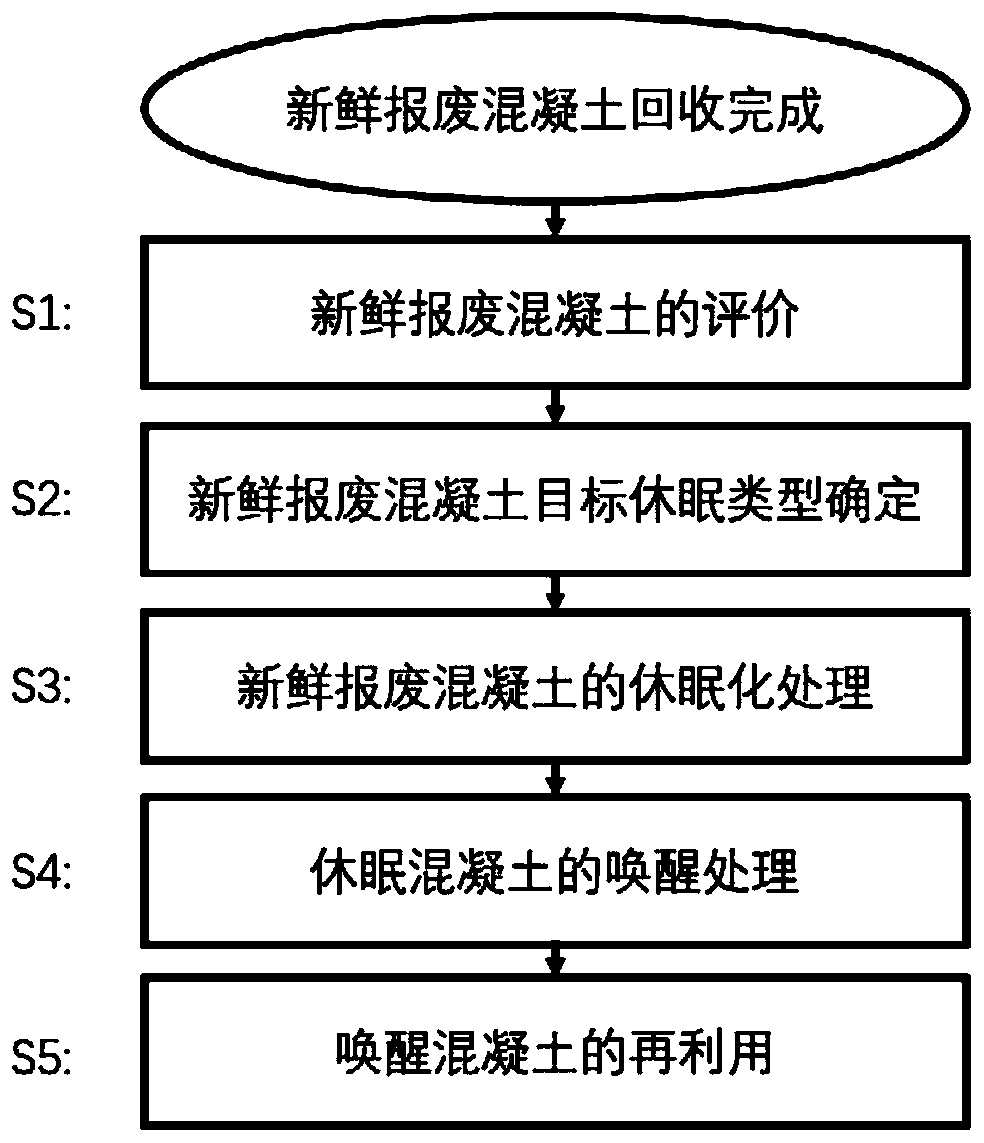

Method used

Image

Examples

Embodiment 1

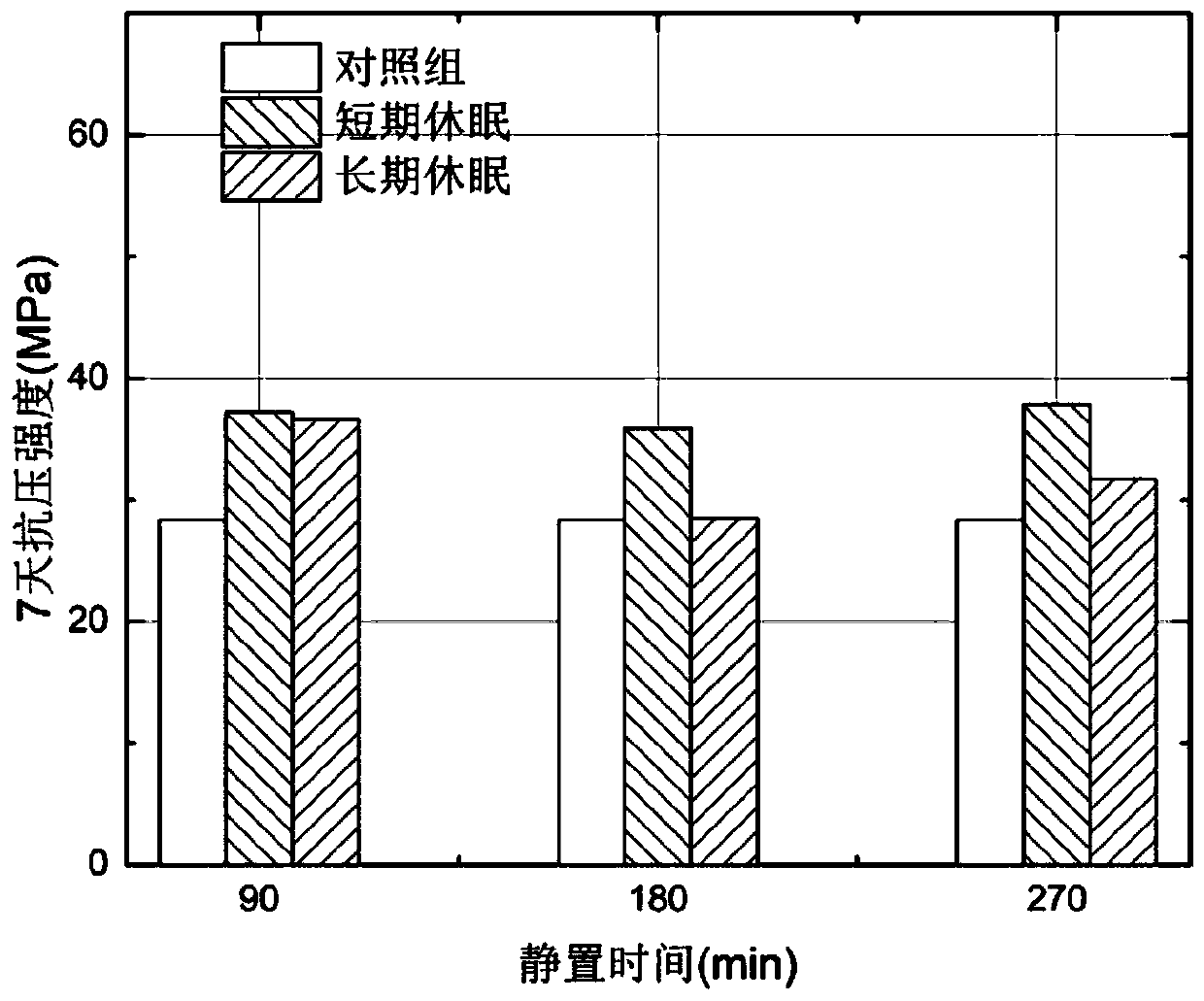

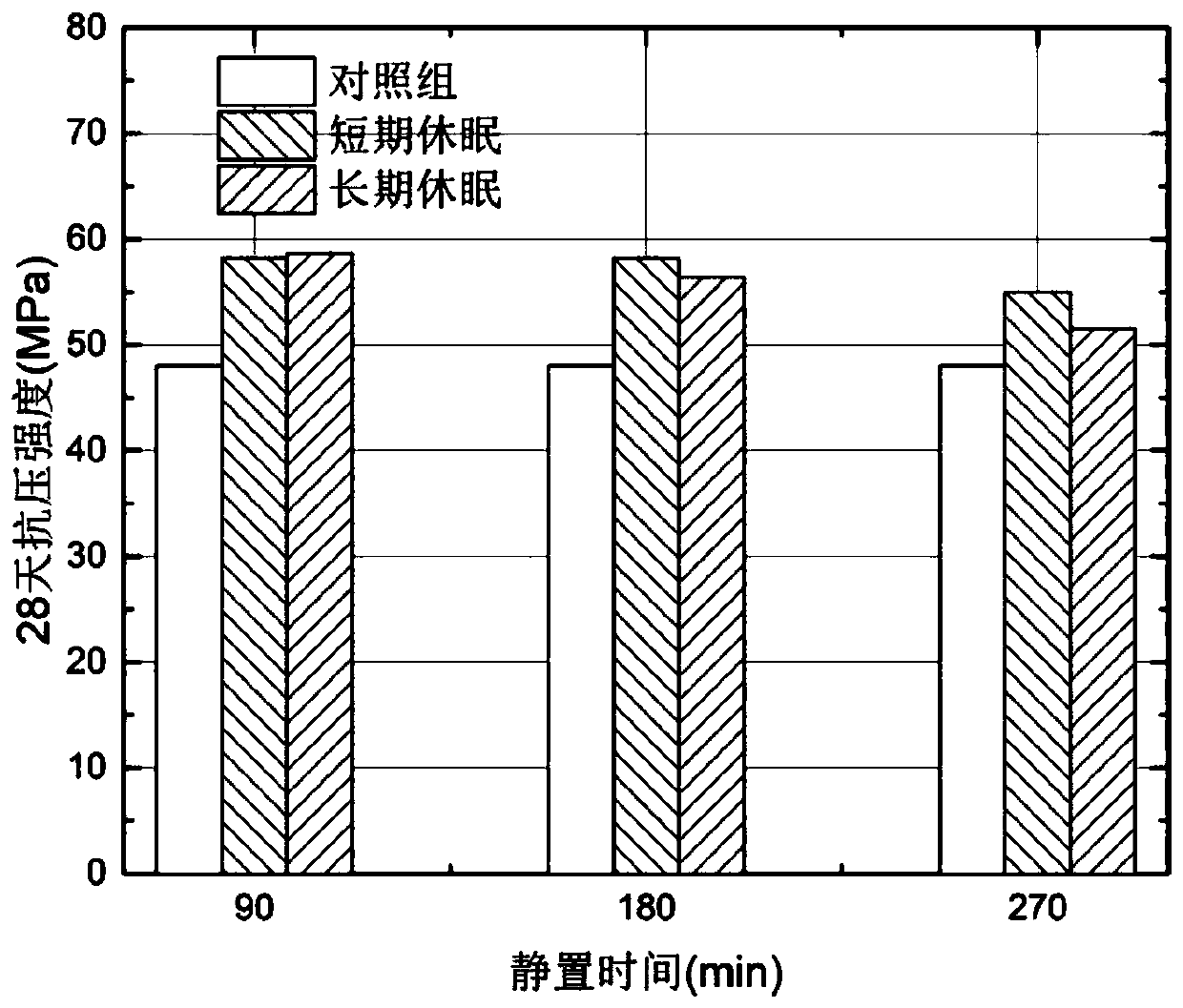

[0139] Fresh scrap concrete was taken as unqualified fresh concrete, and the selected raw materials and mix ratio were the same as the fresh concrete prepared in the comparative example. The selected fresh scrapped concrete should ensure that its strength grade is not lower than the strength grade of the target recycled concrete, and ensure that the time interval between the completion of mixing of fresh scrapped concrete and the addition of dormant agent is ≤ 6h, and that it has a slump that matches its strength grade , specifically, the strength grade of fresh scrap concrete is C45, and the detection volume of the slump matching its strength grade is 2.0L.

[0140] According to the time interval between the completion of mixing of fresh scrapped concrete and the time required for recycling, that is, the standing time, the dormancy type of fresh scrapped concrete is determined as short-term dormancy or long-term dormancy. In this embodiment, the standing time of fresh scrap c...

Embodiment 2

[0145] Fresh scrap concrete was taken as unqualified fresh concrete, and the selected raw materials and mix ratio were the same as the fresh concrete prepared in the comparative example. The selected fresh scrapped concrete should ensure that its strength grade is not lower than the strength grade of the target recycled concrete, and ensure that the time interval between the completion of mixing of fresh scrapped concrete and the addition of dormant agent is ≤ 6h, and that it has a slump that matches its strength grade , specifically, the strength grade of fresh scrap concrete is C45, and the detection volume of the slump matching its strength grade is 2.0L.

[0146] According to the time interval between the completion of mixing of fresh scrapped concrete and the time required for recycling, that is, the standing time, the dormancy type of fresh scrapped concrete is determined as short-term dormancy or long-term dormancy. In this embodiment, the standing time of fresh scrap c...

Embodiment 3

[0151] Fresh scrap concrete was taken as unqualified fresh concrete, and the selected raw materials and mix ratio were the same as the fresh concrete prepared in the comparative example. The selected fresh scrapped concrete should ensure that its strength grade is not lower than the strength grade of the target recycled concrete, and ensure that the time interval between the completion of mixing of fresh scrapped concrete and the addition of dormant agent is ≤ 6h, and that it has a slump that matches its strength grade , specifically, the strength grade of fresh scrap concrete is C45, and the detection volume of the slump matching its strength grade is 2.0L.

[0152] According to the time interval between the completion of mixing of fresh scrapped concrete and the time required for recycling, that is, the standing time, the dormancy type of fresh scrapped concrete is determined as short-term dormancy or long-term dormancy. In this embodiment, the standing time of fresh scrap c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com