Novel method for in-situ stabilizing repairing of lead polluted sediment by using iron-based material synergistic microbes

A technology for iron-based materials and lead pollution is applied in the field of iron-based materials and microorganisms in the field of remediation reagents for lead-contaminated sediments, reagents for remediation of lead-contaminated sediments, and reagents for remediation of lead-contaminated sediments, to reduce mobility and have application prospects. Expansive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The lead-contaminated sediment was taken from the Qingshui Pond in the Xiangjiang section of Zhuzhou, and the sample was air-dried and sieved (60 mesh). The basic property analysis is shown in Table 1.

[0029] Table 1 Basic properties of sediment

[0030] pH 7.8 Organic carbon (g / kg) 7.88 Organic matter (g / kg) 13.59 Cation exchange capacity CEC (cmol / kg) 21.6 Total lead (mg / kg) 733.68

[0031] Preparation of iron-based materials: mix fayalite and oxalic acid dihydrate at a ratio of 2:1, place in a reactor, add deionized water according to a liquid-solid ratio of 4:1, seal it, and heat it up to 90°C for 36 hours , after the reaction is completed, wash, filter and dry.

[0032] Culture of sulfate-reducing bacteria: inoculate Desulfovibrio sp.ATCC 7757 in anaerobic medium (KH 2 PO 4 0.5g / L,NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2 (2.5g / L, sodium lactate 3.5g / L), the pH value is adjusted to 6.5, when growing to the logarithmic...

Embodiment 2

[0038] The sample is the same as in Example 1.

[0039] Preparation of iron-based materials: Mix biotite and oxalic acid dihydrate at a ratio of 3:2, place in a reactor, add deionized water according to a liquid-solid ratio of 5:1, seal it, raise the temperature to 80°C for 12 hours, and react When done, wash, filter and dry.

[0040] Culture of sulfate-reducing bacteria: inoculate Desulfovibrio sp.ATCC 7757 in anaerobic medium (KH2 PO 4 0.5g / L,NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2 (2.5g / L, sodium lactate 3.5g / L), the pH value is adjusted to 6.5, when growing to the logarithmic phase, it is ready for use, and the cell density of the bacterial liquid is 3.2*10 8 individual / mL.

[0041] Remediation of lead-contaminated sediments in a simulated anaerobic environment. The repair experiment was carried out in a 10L reactor. 2kg of sediment samples and 4L of deionized water were added to the reactor successively, and the reactor was divided into four groups: A, B, C and ...

Embodiment 3

[0043] The sample is the same as in Example 1.

[0044] Preparation of iron-based materials: Mix phillips and oxalic acid dihydrate at a ratio of 1:2, place them in a reactor, add deionized water according to a liquid-solid ratio of 4:1, seal, heat up to 90°C for 24 hours, and react When done, wash, filter and dry.

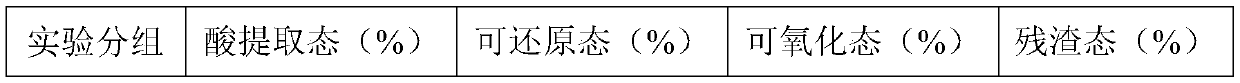

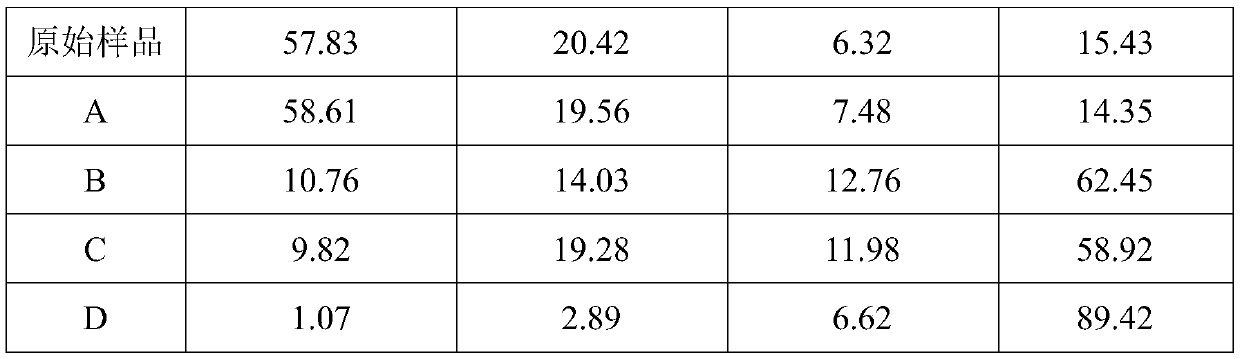

[0045] Table 3 Morphological changes of lead-contaminated sediment before and after immobilization reaction

[0046]

[0047]

[0048] Culture of sulfate-reducing bacteria: inoculate Desulfovibrio sp.ATCC 7757 in anaerobic medium (KH 2 PO 4 0.5g / L,NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2 (2.5g / L, sodium lactate 3.5g / L), the pH value is adjusted to 6.5, when growing to the logarithmic phase, it is ready for use, and the cell density of the bacterial liquid is 3*10 8 individual / mL.

[0049] Remediation of lead-contaminated sediments in a simulated anaerobic environment. The repair experiment was carried out in a 10L reactor. 2kg of sediment samples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com