Kitchen garbage crushing and recycling mechanism

A kitchen waste and crushing box technology, which is applied in the direction of garbage collection, garbage cans, applications, etc., can solve the problems of rough operation, unsuitable, large floor space, etc., and achieve simple structure, convenient operation, and increased garbage disposal volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

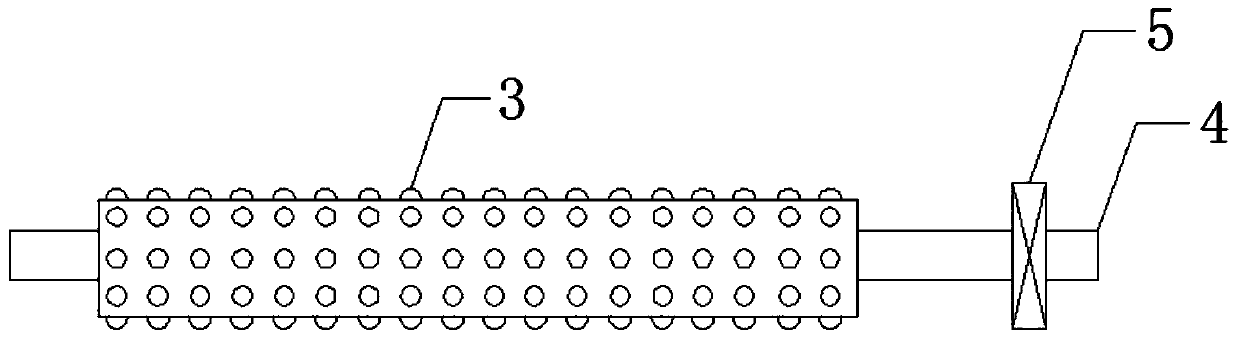

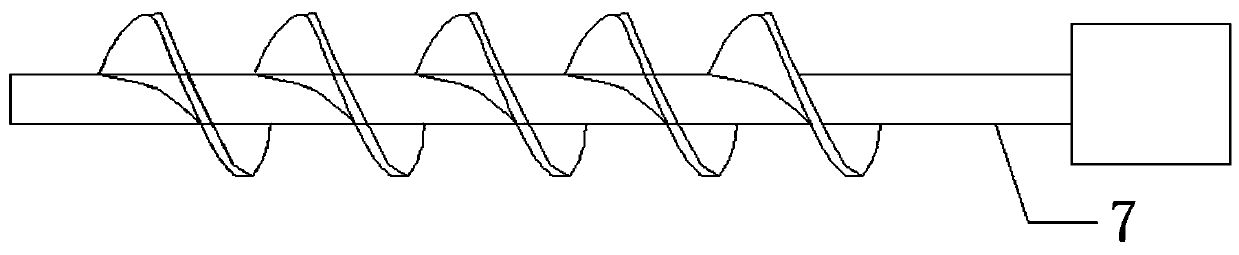

[0019] Such as Figure 1-3 As shown, the present invention provides a mechanism for crushing and reusing kitchen waste, including a crushing box 1, a sewage tank 8 and a garbage box 11. The top of the crushing box 1 is provided with a garbage inlet 2, and the bottom of the crushing box 1 is provided with a sewage Box 8, one side of crushing box 1 is provided with dustbin 11, and the inside of crushing box 1 is equipped with several crushing rollers 3, and the lower end of crushing box 1 inside is movable to be equipped with conveying auger 7, and the two ends of crushing rollers 3 are installed The shaft 4 is movably connected with the crushing box 1, and one end of one of the installation shafts 4 is connected to the motor 6 through transmission, and the adjacent installation shafts 4 are connected through the transmission wheel 5, and one end of the feeding auger 7 is connected to the motor 6 through transmission. The bottom of the other end is provided with a material deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com