Process for deep purification and recovery of mercury in lead-zinc smelting flue gas

A technology of smelting flue gas and deep purification, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of high operating cost, increased system resistance, and general mercury removal effect of activated carbon adsorption method, and achieve technology saving Transformation costs, meet environmental protection requirements, and the effect of simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

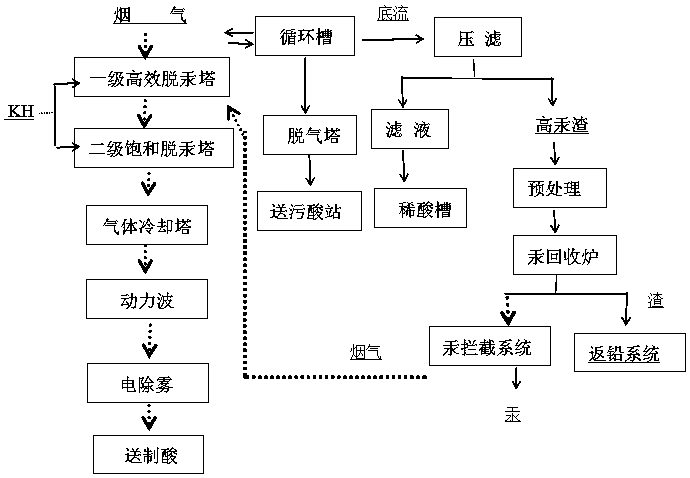

Image

Examples

Embodiment 1

[0023] A domestic lead smelting furnace flue gas mercury removal demonstration project, the demonstration project was constructed in early 2108, adopts the mercury deep purification and mercury recovery process in the lead-zinc smelting flue gas of the present invention, including the following steps:

[0024] Step 1: Turn on the dispensing tank to stir, weigh the KH powder material and pure water to make a KH slurry with a concentration of 40% to 60%.

[0025] Step 2: Input the flue gas into the primary mercury removal tower, and then add the prepared KH slurry in the primary mercury removal tower according to the mercury content of the flue gas, the mercury content of the flue gas is the same as the added KH slurry The mass ratio is 1:10, the automatic dosing device is turned on, and the KH slurry is fed into the tower at a uniform speed. It is best to add KH slurry when the temperature of the flue gas is in the range of 100°C to 300°C, so as to enhance the activity of the K...

Embodiment 2

[0032] This process is used to treat flue gas from a zinc smelting company in China. The company originally used the Polyton method to treat mercury in the flue gas. Later, this process was transformed in another zinc smelting system of the company. The process steps are as follows:

[0033] Step 1: Prepare KH powder material and purified water to make KH slurry with a concentration of 50%.

[0034] Step 2: Input the flue gas into the primary mercury removal tower, and then add the prepared KH slurry in the primary mercury removal tower according to the mercury content of the flue gas, the mercury content of the flue gas is the same as the added KH slurry The mass ratio is 1:10, the automatic dosing device is turned on, and the KH slurry is fed into the tower at a uniform speed.

[0035] Step 3: Input the flue gas after mercury removal in the primary mercury removal tower to the secondary saturated mercury removal tower, add excess KH slurry to the secondary saturated mercury ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com