A kind of royal jelly automatic insect suction device

A royal jelly and automatic technology, which is applied in the field of agricultural engineering, can solve the problems of limiting royal jelly extraction efficiency, slow filter time, troublesome replacement and cleaning, etc., to achieve the effect of ensuring product quality, fast pulp extraction speed, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

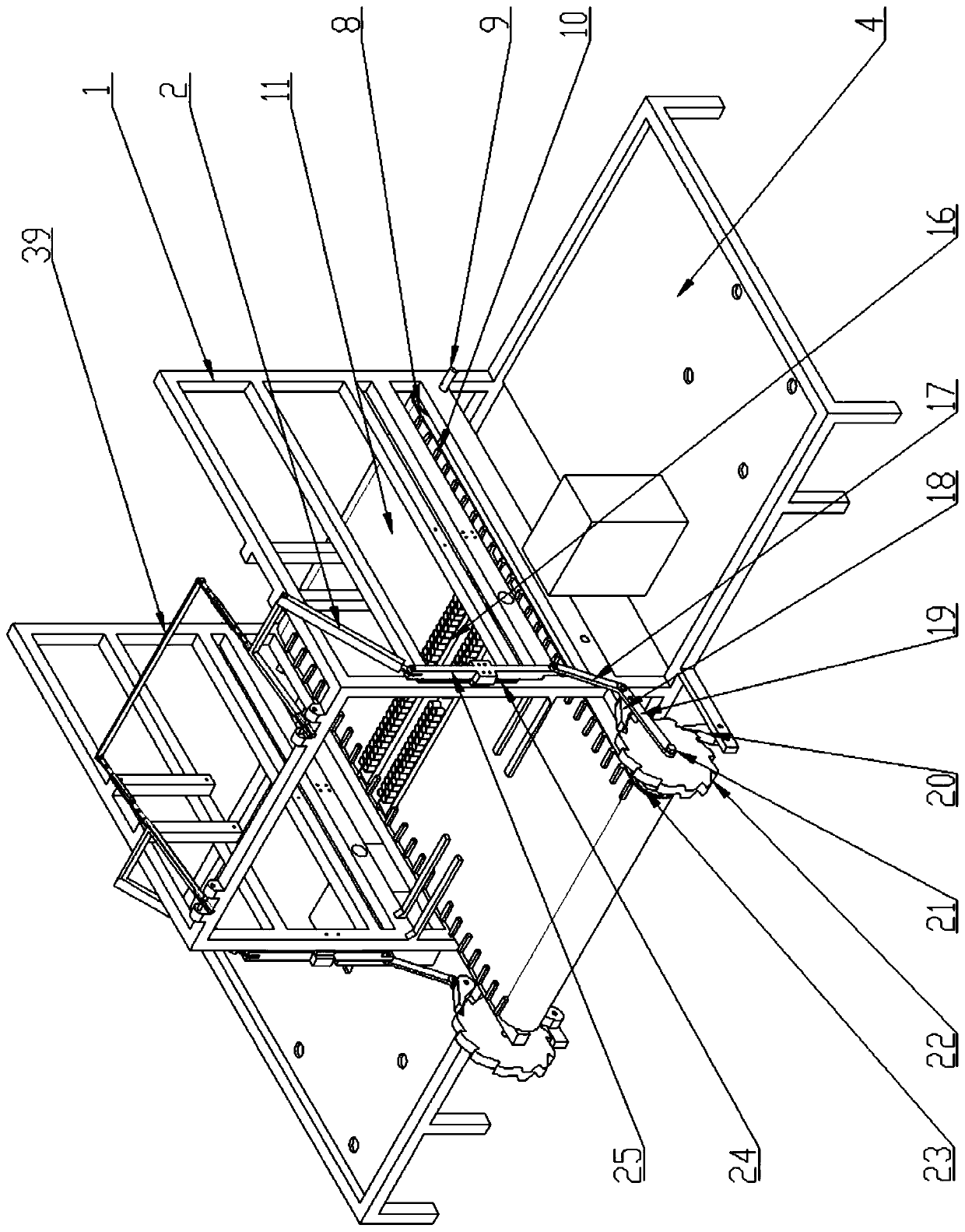

[0056] An automatic royal jelly extraction and suction device for insects comprises a frame 1, a working platform 4, a transmission device, an insect extraction device and a slurry suction device.

[0057] Such as Figure 1-4 , wherein, the frame 1 is located on the working platform 4, and the frame 1 is provided with a rocker 39 in a "Xi" type structure, which is connected with the frame 1 by pins to form a rotating pair;

[0058] The transmission device includes a conveyor belt 11 straddling the working platform 4, a driving roller 23 and a driven roller 8 that drive the conveyor belt 11 to move, and a ratchet mechanism that drives the driving roller 23 and the driven roller 8 to rotate intermittently. Such as figure 2 , Figure 5 , The ratchet mechanism is located at both ends of the driving roller 23, including a ratchet 22, a ratchet lever 19 and a ratchet 18 mounted on the ratchet lever 19. The ratchet 18 and the ratchet lever 19 are connected by pins to form a revol...

Embodiment 2

[0063] On the basis of embodiment 1, the royal jelly automatic extraction and suction device for insects of the present embodiment has been further improved. Such as Figure 5 , Image 6 , wherein, the driving device includes a cam 31 and a linear roller guide 32 (model MGN9H); the linear roller guide 32 is symmetrically installed on both sides of the frame 1, and the insect collection box 7 is fixed on the slider of the linear roller guide 32 , the roller follower 41 (model 688ZZ) on the cam 31, the insect collection box 7 and the roller linear guide 32 are installed to the center, so as to realize the left and right movement of the insect collection box 7 on the frame 1; The long connecting rods 40 are connected by pins through the cam connecting rods 29 to form a revolving pair. Symmetrical inserts 10 are arranged on the conveyor belt 11 , and the distance between two adjacent inserts 10 is equal to the width of the pulp production bar 16 , forming a space for placing the...

Embodiment 3

[0065] On the basis of embodiment 2, the royal jelly automatic extracting and sucking device for worms of the present embodiment has been further improved. Among them, such as Image 6, the driving device also includes a power unit, which is composed of a motor 13 (model F86-H125) and a shaft coupling 14 (model SXL-40), connected with the cam 31, located on the working platform 4, the output end of the motor 13 It is connected with the third transmission shaft 28 through the coupling 14 , and the cam 31 is installed on the frame 1 through the third transmission shaft 28 .

[0066] Such as Figure 7 , Figure 8 , The suction head 27 includes a plurality of suction heads 42 , an inner hollow pipe 43 and a manifold 44 , and the suction head 27 is fixed on the suction head support 30 through a fixing seat 46 . Suction head 42 is a hollow suction pipe structure, in an inverted cone shape, the inner diameter of the head is smaller than the inner diameter of the root, installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com