A cable bonding device

A technology for cables and appliances, applied in the field of cable splicing appliances, can solve the problems of wasting more time, rising costs, and prolonging the progress of cable construction projects, and achieves the effects of strong functionality, prolonged progress, complete moisture resistance and insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

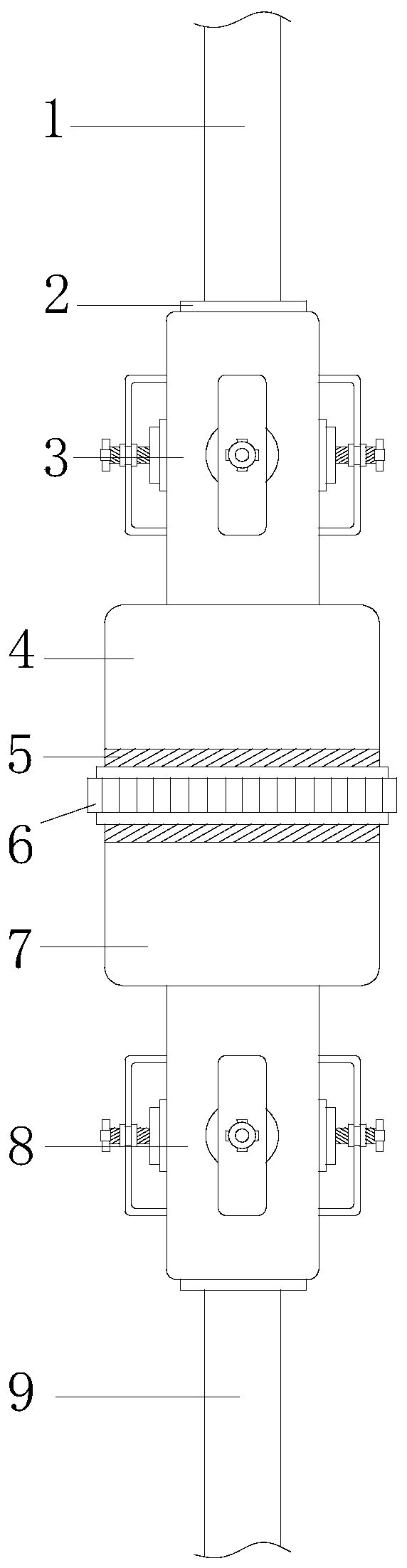

[0028] see figure 1, a cable lapping device, its structure includes a first cable 1, a sealing ring 2, an upper cable locking sleeve 3, an upper conductor connecting sleeve 4, a thread groove 5, a locking spiral ring 6, a lower conductor connecting sleeve 7. The lower cable locking sleeve 8, the second cable 9, the upper conductor connecting sleeve 4 is provided with a threaded groove 5, the upper conductor connecting sleeve 4 is provided with a locking screw ring 6, the described The locking screw ring 6 and the thread groove 5 are threaded, and the upper conductor connecting sleeve 4 and the lower cable locking sleeve 8 are connected through the locking screw ring 6, and the upper and lower ends of the locking screw ring 6 are respectively An upper cable locking sleeve 3 and a lower cable locking sleeve 8 are provided, and the upper cable locking sleeve 3 and the lower cable locking sleeve 8 have an axisymmetric structure, and the upper cable locking sleeve 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com