Multifunctional flexible sensing material and preparation method and application thereof

A sensing material and multi-functional technology, applied in chemical instruments and methods, using electric/magnetic devices to transmit sensing components, measuring the properties and forces of piezoelectric resistance materials, etc., can solve the development of multi-functional flexible sensing materials Insufficient, complex preparation process of flexible sensing materials, inconvenient large-scale production and application, etc., to achieve good sensory feedback ability, good cycle stability, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

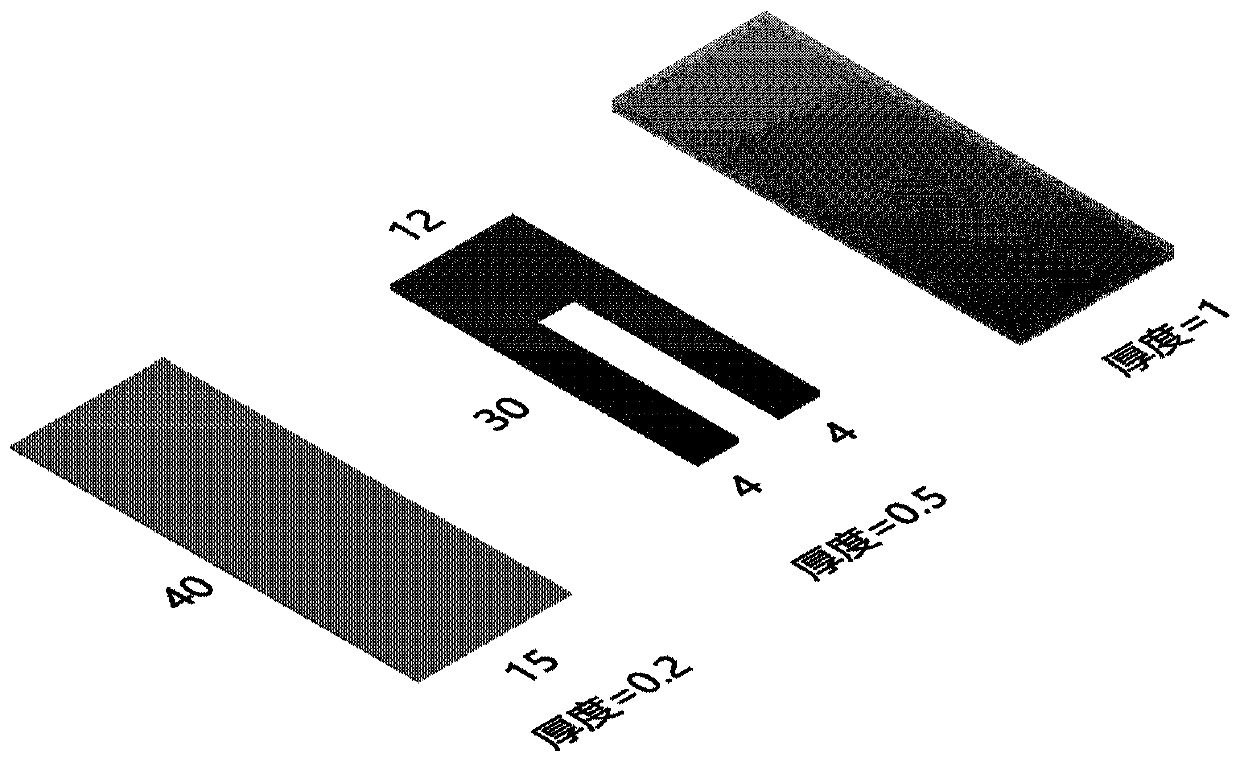

[0043] According to some embodiments of the present invention, there is also provided a method for preparing the multifunctional flexible sensing material as described above, comprising the following steps:

[0044] Prepare magnetorheological layer and conductive layer respectively;

[0045] The magnetorheological layer and the conductive layer are stacked and assembled to obtain a multifunctional flexible sensing material.

[0046] Wherein, the magnetorheological layer is prepared through the following steps:

[0047] a. Mix the silicone rubber matrix with the magnetic particles;

[0048] b. Carrying out vacuum degassing treatment to the mixture obtained in step a;

[0049] c. Carrying out room temperature curing treatment to the vacuum-treated mixture;

[0050] The conductive layer is prepared by the following steps:

[0051] d. mixing the silicone rubber matrix with conductive nanoparticles;

[0052] e. carrying out vacuum degassing treatment to the mixture obtained in...

Embodiment 1-1

[0063] Get the raw material of following mass fraction:

[0064] Ecoflex 0030 A: 25%

[0065] Ecoflex 0030 B: 75%

[0066] The preparation steps of the silicone rubber matrix are as follows:

[0067] Mix Ecoflex 0030 A and Ecoflex 0030 B uniformly for 2 to 3 minutes to obtain the required silicone rubber matrix, among which Ecoflex 0030 A and Ecoflex 0030 B are purchased from Dow Corning Smooth-On Series.

Embodiment 1-2

[0069] Get the raw material of following mass fraction:

[0070] Ecoflex 0030 A: 50%

[0071] Ecoflex 0030 B: 50%

[0072] Others are the same as embodiment 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com