Multifunctional flexible sensing equipment and preparation method thereof

A multi-functional and flexible technology, applied in the field of smart wearables, can solve the problems of design difficulties, lack of wearable equipment, inconvenient mass production and application, etc., and achieve the effect of good protection and warmth, and good sensory feedback capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation method of shear hardening glue is as follows:

[0060] Get the raw materials of following mass ratio:

[0061] Silicone oil: boric acid = 40:1

[0062] Mix and stir 100g of silicone oil and 2.5g of boric acid, put it in an oven with a temperature of 180 degrees Celsius, and after the silicone oil coagulates into a block, add 250 μL of n-octanoic acid, wait until the n-octanoic acid softens the agglomerate, and stir again. Put it back into an oven at 180°C and continue heating for 15 minutes before taking it out.

[0063] Wherein: said silicone oil is QK-501 hydroxyl silicone oil of Shenzhen Qianjing Technology Development Co., Ltd., with a viscosity of 15-30 at 25 degrees Celsius and a hydroxyl content of 8-9.

Embodiment 2

[0065] The preparation method of shear hardening glue is as follows:

[0066] Get the raw materials of following mass ratio:

[0067] Silicone oil: boric acid = 30:1

[0068] Mix and stir 100g of silicone oil and 3.33g of boric acid, put it in an oven with a temperature of 180 degrees Celsius, and after the silicone oil has coagulated into a block, add 250 μL of n-octanoic acid, wait until the n-octanoic acid softens the agglomerate, and stir again. Put it back into an oven at 180°C and continue heating for 15 minutes before taking it out.

[0069] Wherein: said silicone oil is QK-501 hydroxyl silicone oil of Shenzhen Qianjing Technology Development Co., Ltd., with a viscosity of 15-30 at 25 degrees Celsius and a hydroxyl content of 8-9.

Embodiment 3

[0071] The preparation method of shear hardening glue is as follows:

[0072] Get the raw materials of following mass ratio:

[0073] Silicone oil: boric acid = 20:1

[0074] Mix and stir 100g of silicone oil and 5g of boric acid, and put it in an oven at 180 degrees Celsius. After the silicone oil is coagulated into a block, add 250 μL of n-octanoic acid. After the n-octanoic acid softens the agglomerate, stir again. Put it back into an oven at 180°C and continue heating for 15 minutes before taking it out.

[0075] Wherein: said silicone oil is QK-501 hydroxyl silicone oil of Shenzhen Qianjing Technology Development Co., Ltd., with a viscosity of 15-30 at 25 degrees Celsius and a hydroxyl content of 8-9.

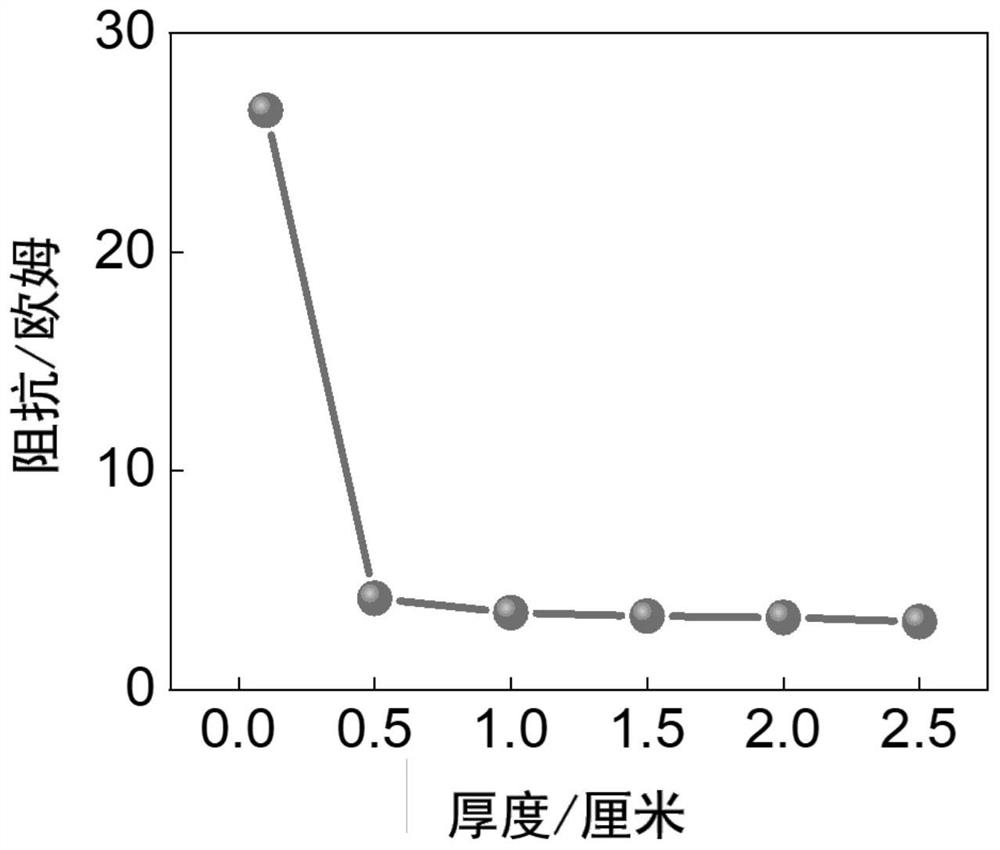

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com