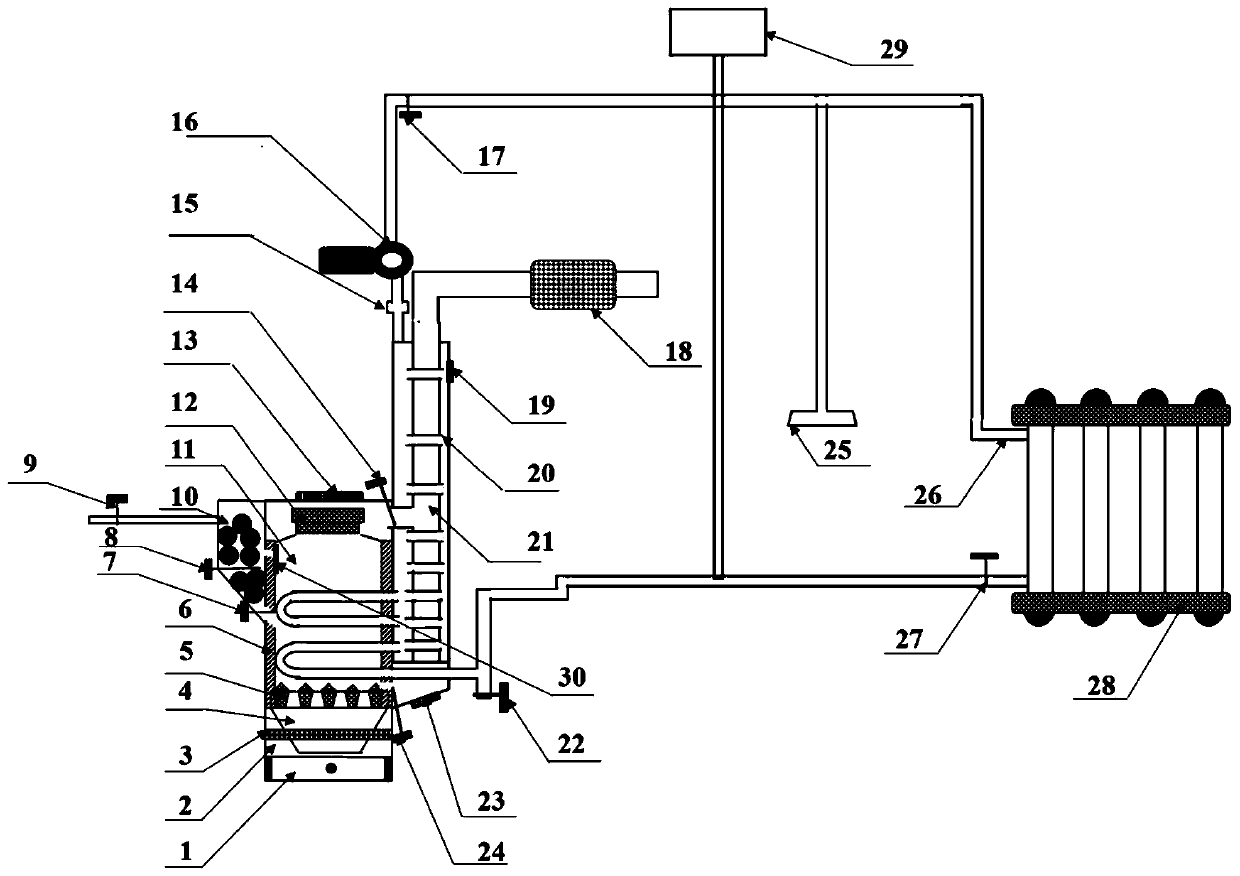

Clean and safe combustion system and method

A combustion system and safety technology, applied in the field of clean and safe combustion system, can solve the problems of poor fuel quality and low efficiency of stoves, and achieve the effects of less pollution emissions, strong fuel applicability, and lightening the burden on the people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The ignition fuel is ignited in the furnace, and the biomass coal fuel is added to the fuel storage room 10 for low-temperature pyrolysis, and the pyrolysis gas inlet channel and the switch 9 are opened to allow the pyrolysis gas to enter the combustion chamber 11 for full combustion. Move left and right to move the airflow control plate 3 to adjust the size of the grid holes on the furnace body to increase the air intake appropriately, close the lower smoke control valve 24, open the upper smoke control valve 14 so that the flame is concentrated on the upper part of the combustion chamber 11, open The fire sealing cover 13 and the fire collecting cover 13 on the top of the gasification tray 12 are used as cooking purposes. The flue gas is only discharged through the passage where the upper flue gas control valve 14 is located. The double-layer hob and local pressurized structure make the airflow smoothly enter the combustion chamber 11 for combustion support, and the b...

Embodiment 2

[0040] The ignition fuel is ignited in the combustion chamber 11, and the biomass molding fuel is added to the fuel storage room 10 for low-temperature pyrolysis, and the pyrolysis gas recovery channel and switch 9 are opened to allow the pyrolysis to be stored in the storage tank through the booster pump to avoid incomplete combustion. Pollution emissions and energy waste. Move the airflow control plate left and right to adjust the size of the grid holes on the furnace body to appropriately reduce the air intake, and at the same time open the lower flue gas control valve 24 and the upper flue gas control valve 14 and close the top fire sealing cover and collector of the gasification tray 12. The fire hood 13 is used for heating. Due to the function of sealing the fire, a CO alarm needs to be installed to prevent danger from happening. At the same time, the smoke is discharged through the passage where the upper smoke control valve 14 and the lower smoke control valve 24 are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com