Dual-pulse solid rocket engine soft interlayer ablation test device

A solid rocket and ablation test technology, which is applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems that the double pulse engine II pulse soft compartment is difficult to simulate and observe, and achieve the free length of the grain Adjustable, simple structure, the effect of free control of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

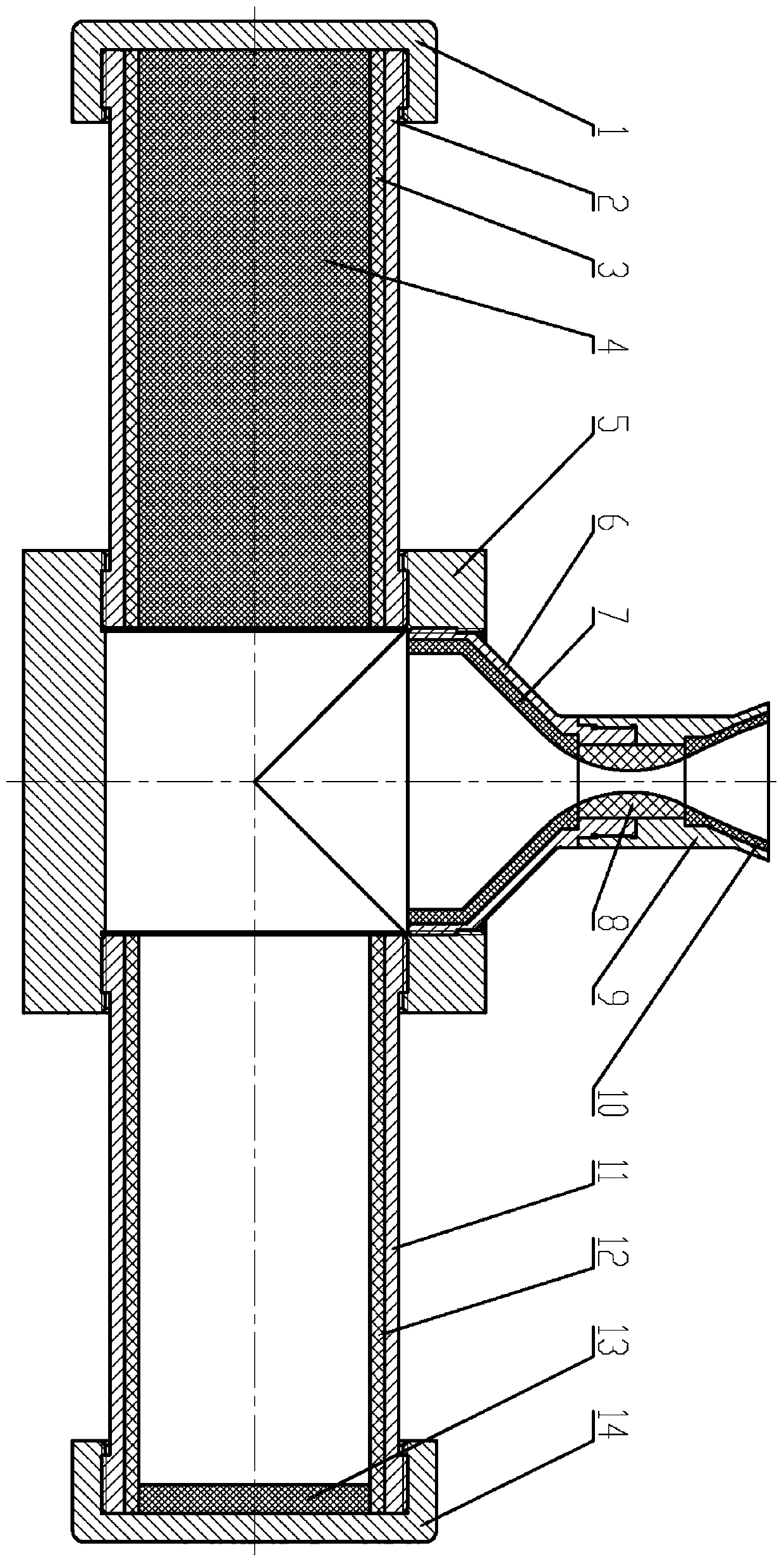

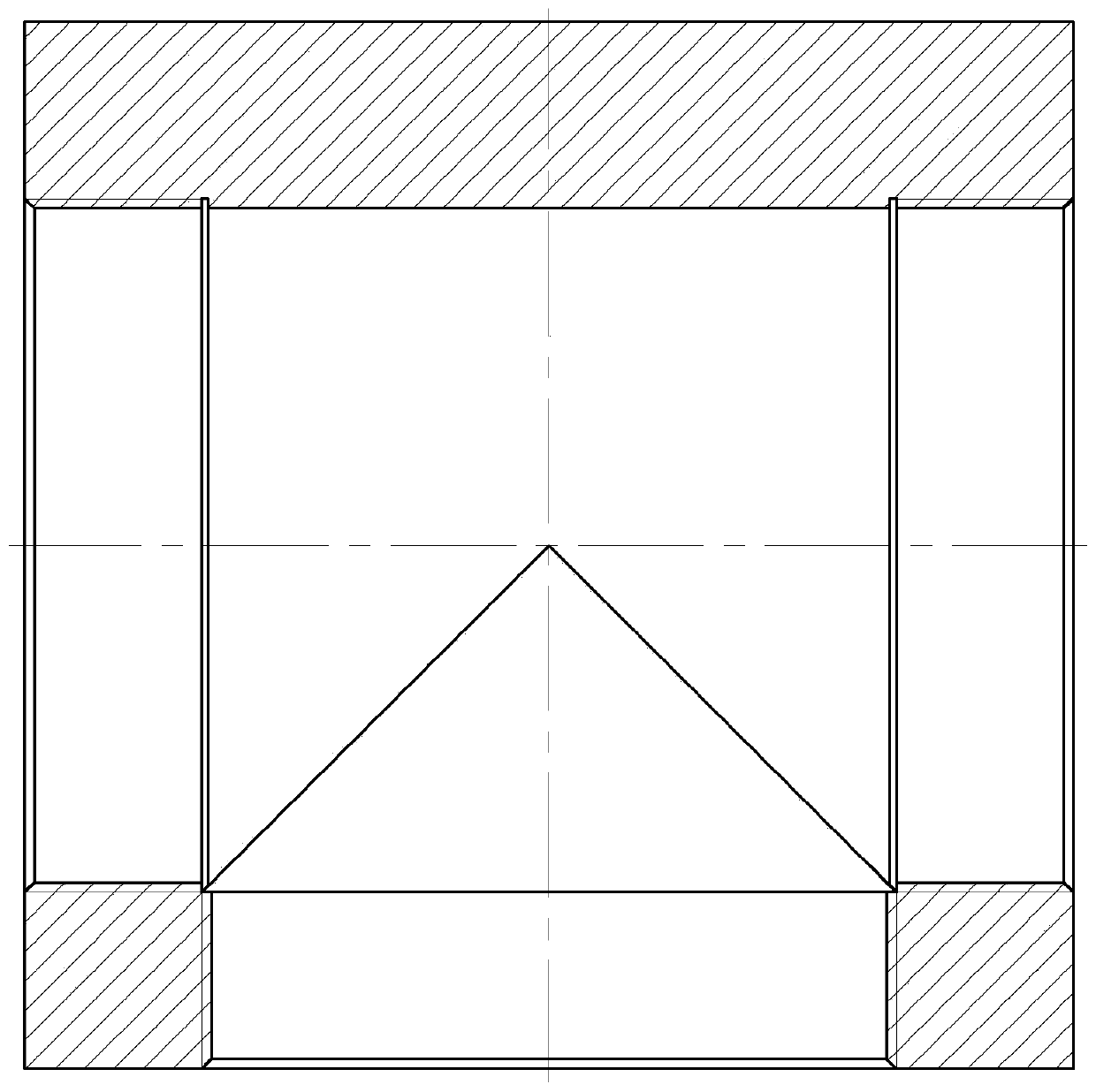

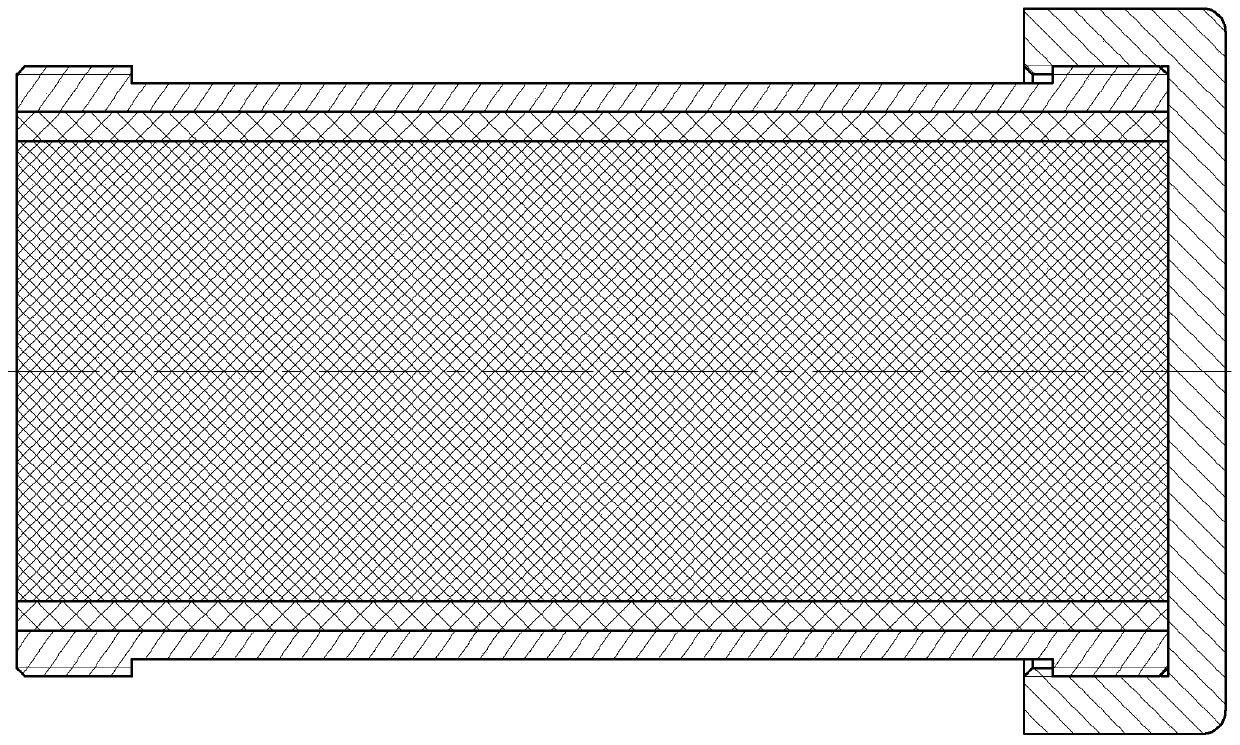

[0024] combine figure 1 , a double-pulse solid rocket motor soft interlayer ablation test device, which is used to study the mass transfer and heat transfer ablation process of thermal insulation materials, and has important reference value for the design of thermal protection structures of engines. The end-burning charge cavity plugging cover 1 of the test device, the end-burning charge cavity shell 2, the central cubic connector 5, the nozzle cavity shell 6, the rear section of the nozzle cavity 9, the test piece burning The corrosion chamber shell 11 and the test piece ablation chamber plug cover 14 are all made of high-strength 45 steel materials; Both the lining 10 and the inner lining 12 of the ablation cavity of the specimen are made of EPDM rubber; the throat lining 8 of the nozzle cavity is made of graphite. All three cavities are connected with the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com