Steel plate combined shear wall with honeycomb partition plates arranged in staggered manner, outer frame and preparation method

A technology of combined shear walls and staggered arrangement, which is applied in the direction of walls, building materials, and building components, can solve the problems of unfavorable local stability of outsourcing steel plates, low overall stiffness of shear walls, and poor stability of outsourcing steel plates, etc., and achieve local Advantageous stability control, improved local stability, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

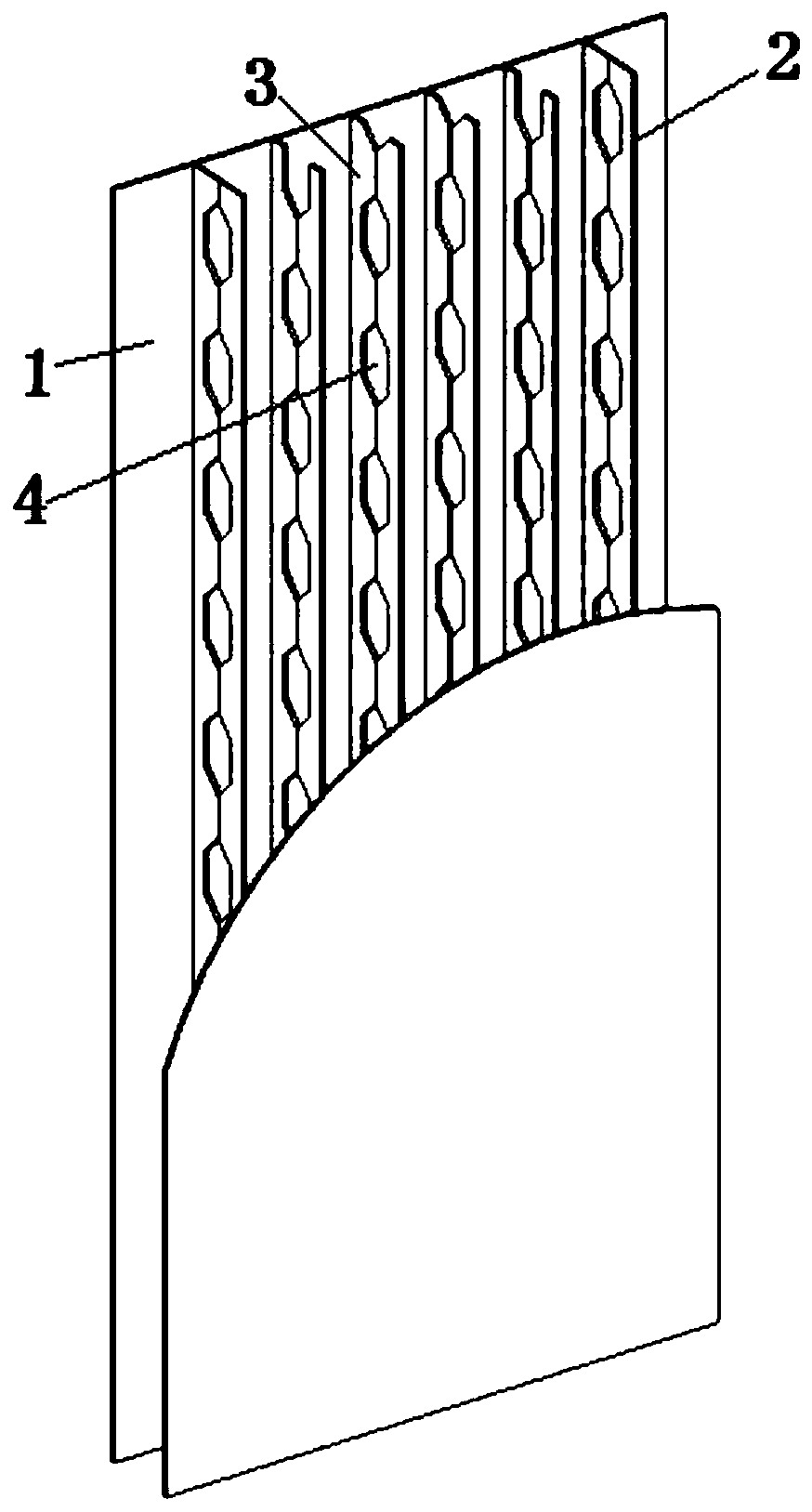

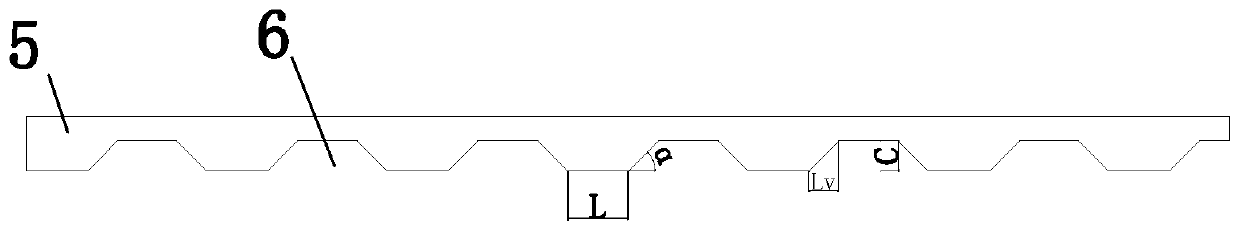

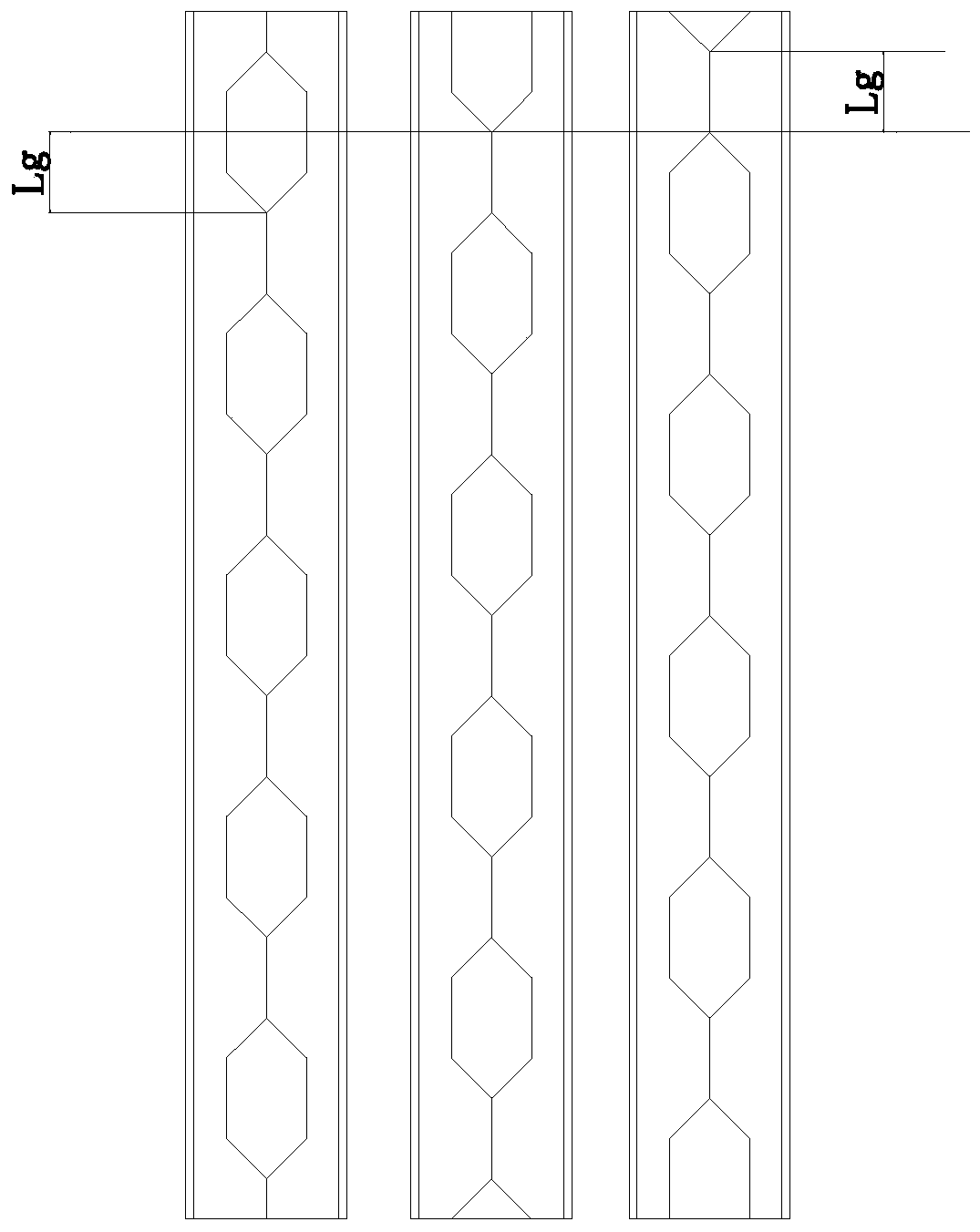

[0032] Example. The composite steel plate shear wall with honeycomb partitions arranged in staggered arrangement is as follows: Figure 1 to Figure 9 As shown, it includes two outsourcing steel plates 1 arranged in parallel, and one or more sets of honeycomb partitions 2 are arranged between the two outsourcing steel plates 1, and the honeycomb partitions 2 and the outsourcing steel plates 1 are perpendicular to each other; the honeycomb The type separator group 2 includes a plurality of separators 3 arranged side by side, and each separator 3 is provided with a group of honeycomb holes 4 that are evenly distributed up and down, and the honeycomb holes 4 on adjacent separators 3 are arranged in a misplaced manner. ; The separator 3 includes two welded and fixed separating veneers 5, and each separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com