Anti-deflection construction method for large-area network frame high-altitude cantilever installation

A construction method and large-area technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of uneconomical, labor-intensive, slow construction period, etc., to save rental costs, avoid production costs, and speed up construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

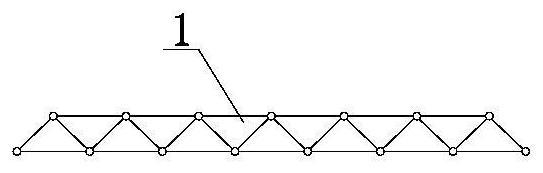

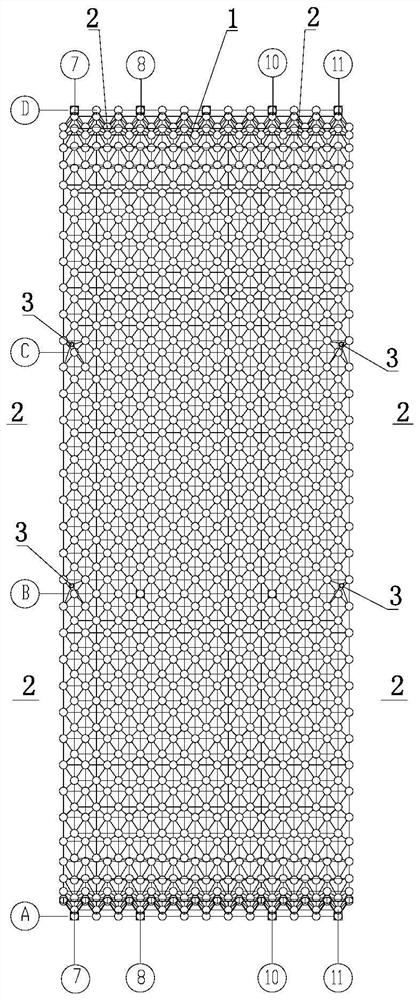

[0027] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings: the design concept of the present invention is to first complete the installation of the starting span; When the cantilever is installed to about 3 grids, the poles on the poles are used to form a stable support structure, which can effectively prevent the grid frame from deflecting.

[0028] combined with Figure 1-10 And an embodiment of the present invention specifies construction method of the present invention:

[0029] (1) The network frame constructed in this example spans 16 axes as a whole, and the figures are respectively marked by ①- It is indicated that according to this construction method, the two grid structures between the ⑧ and ⑩ axes are used as the starting span 1, and the first step of construction is carried out, and the step spans are installed according to the usual grid installation method.

[0030] (2) With the starting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com