Powder automatic adding device control system

A device control and automatic adding technology, which is applied in the direction of conveyor control device, packaging, loading/unloading, etc., can solve the problems of automatic powder adding, which cannot be realized, and the degree of automation of powder adding equipment is low, so as to achieve a high degree of control automation , strong versatility, reasonable planning of control process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

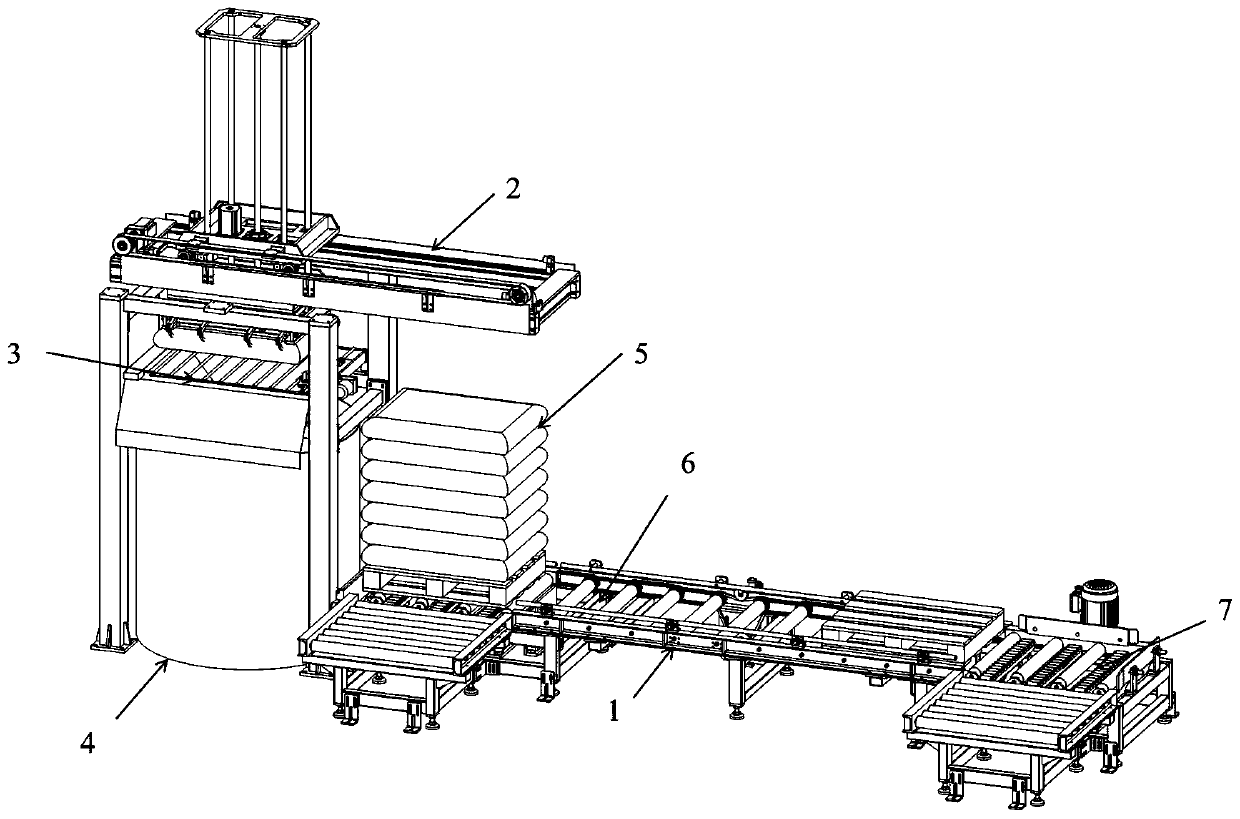

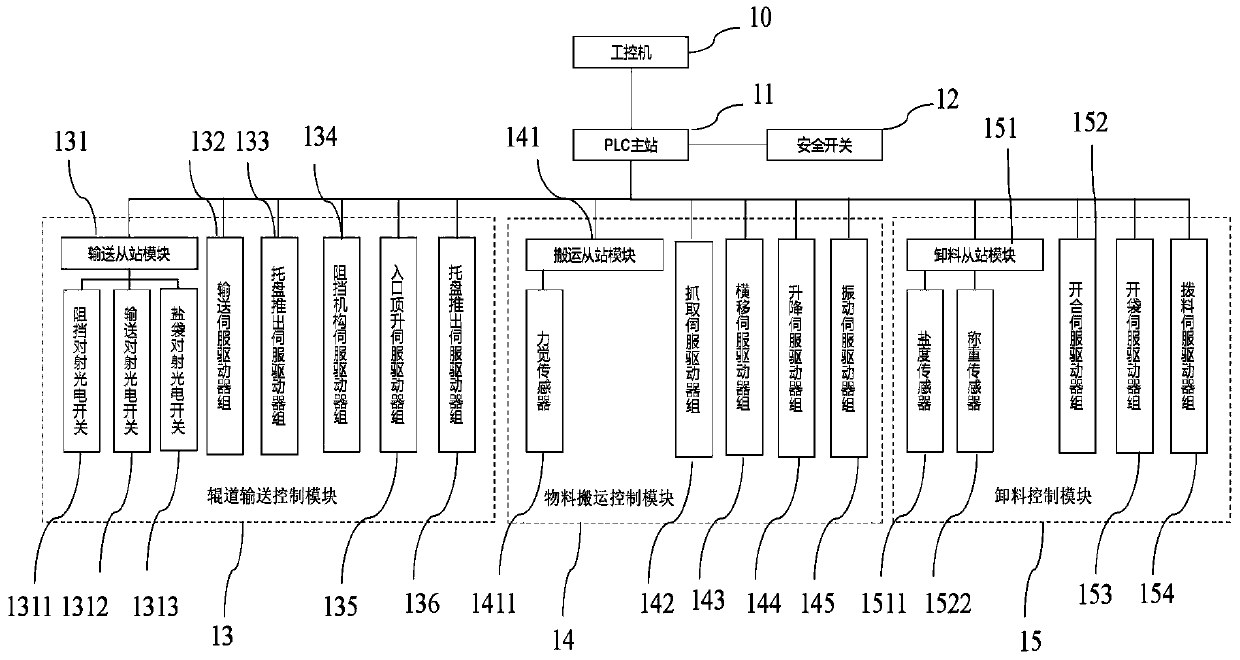

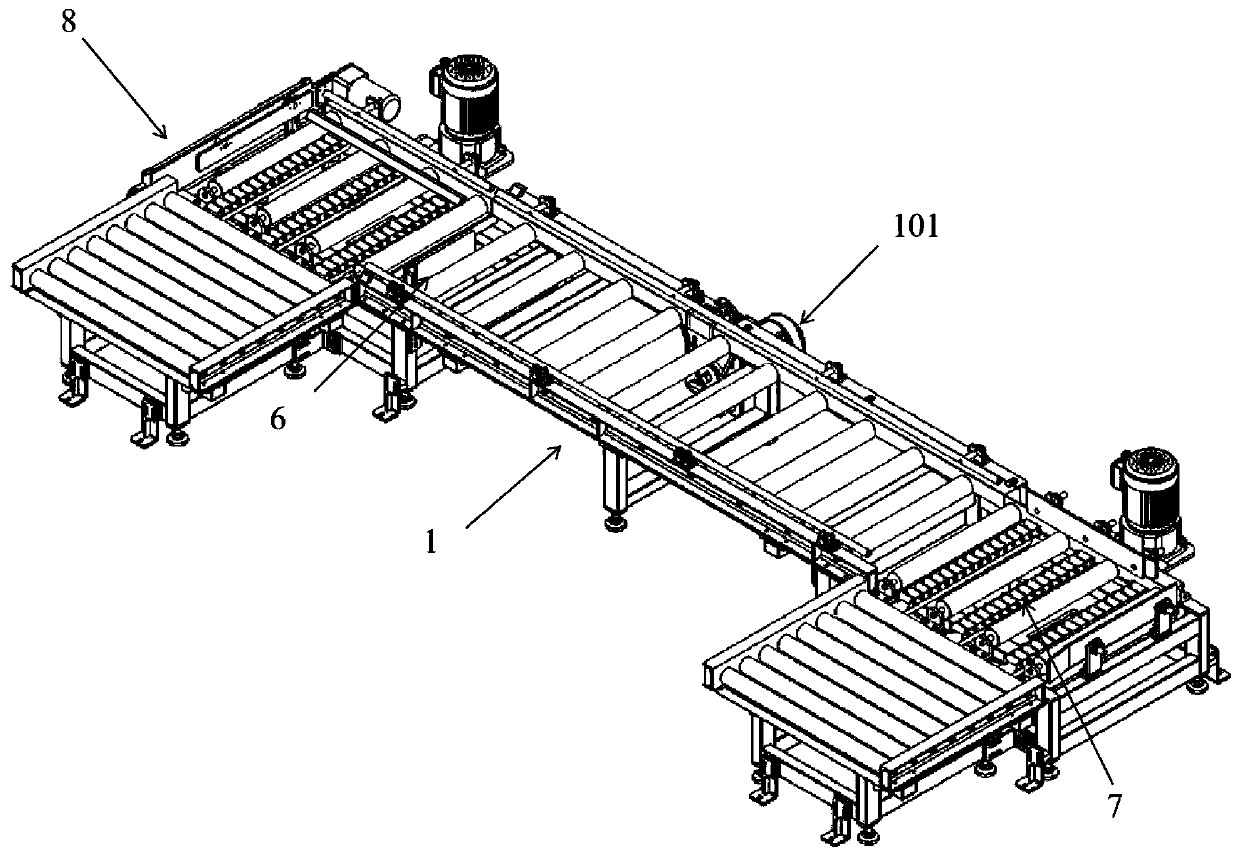

[0027] Regular addition of industrial salt to the external cooling system of the converter valve has the following beneficial effects: to ensure the removal of calcium and magnesium ions in the water, to prevent fouling of the cooling pipes, and to obtain the best heat exchange efficiency. In this embodiment, the external cooling of the converter valve For example, the process of automatically adding salt bags by the system, see Figure 1 to Figure 10 , the control system in the present invention is applied to the automatic powder addition device, and the automatic powder addition device includes a roller conveyor 1, a material handling device 2, a powder bag unloading device 3 and a silo 4; the roller conveyor 1 is installed There is a blocking mechanism 6; the silo 4 is set at the end of the conveying direction of the roller conveyor 1; the powder bag unloading device 3 includes a discharge silo 31 and a bag opening mechanism 32, and the discharge silo 31 is located directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com