Method for strengthening construction unit using high strength fibre cloth

A technology of reinforcing components and high-strength fibers, applied in building components, building reinforcements, structural elements, etc., can solve the problems of easy aging, affecting long-term effects, and inability to adjust the stress state of the original structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

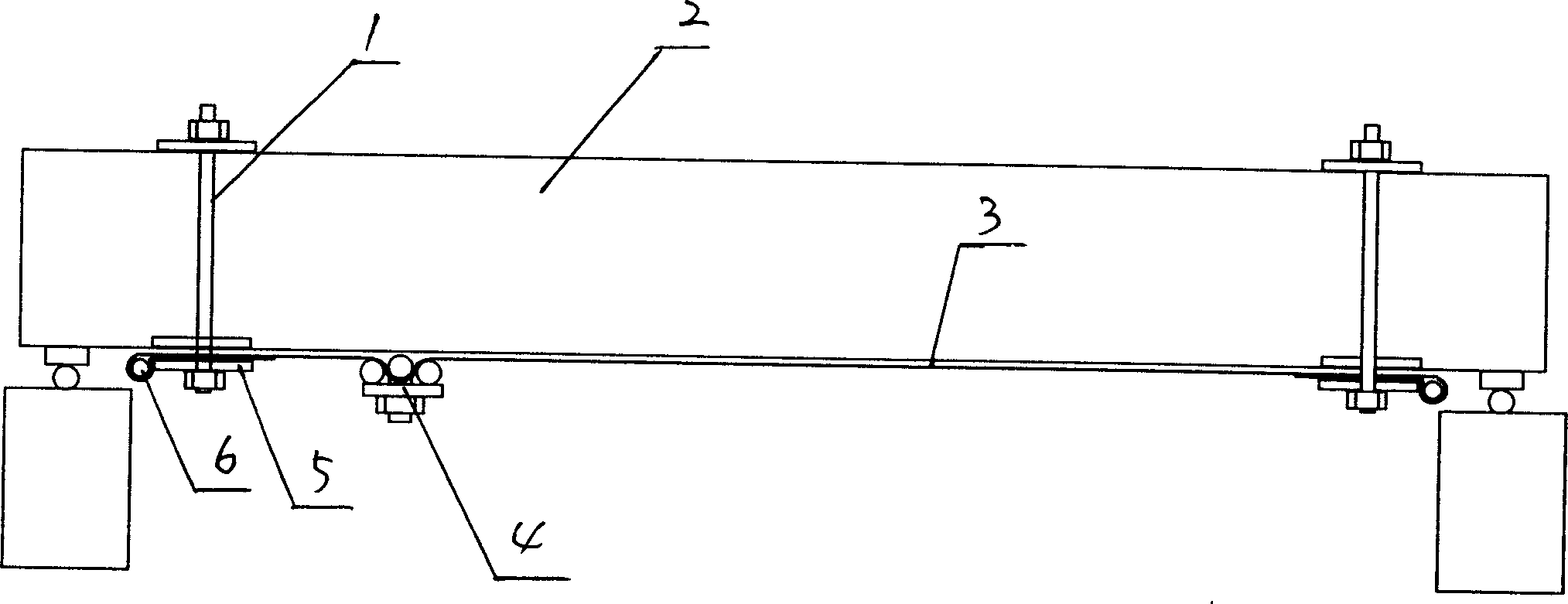

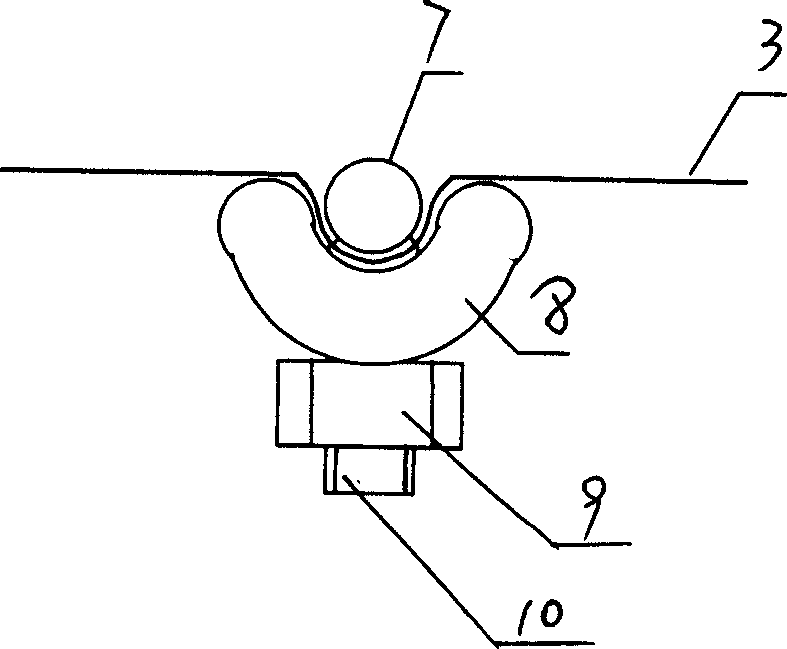

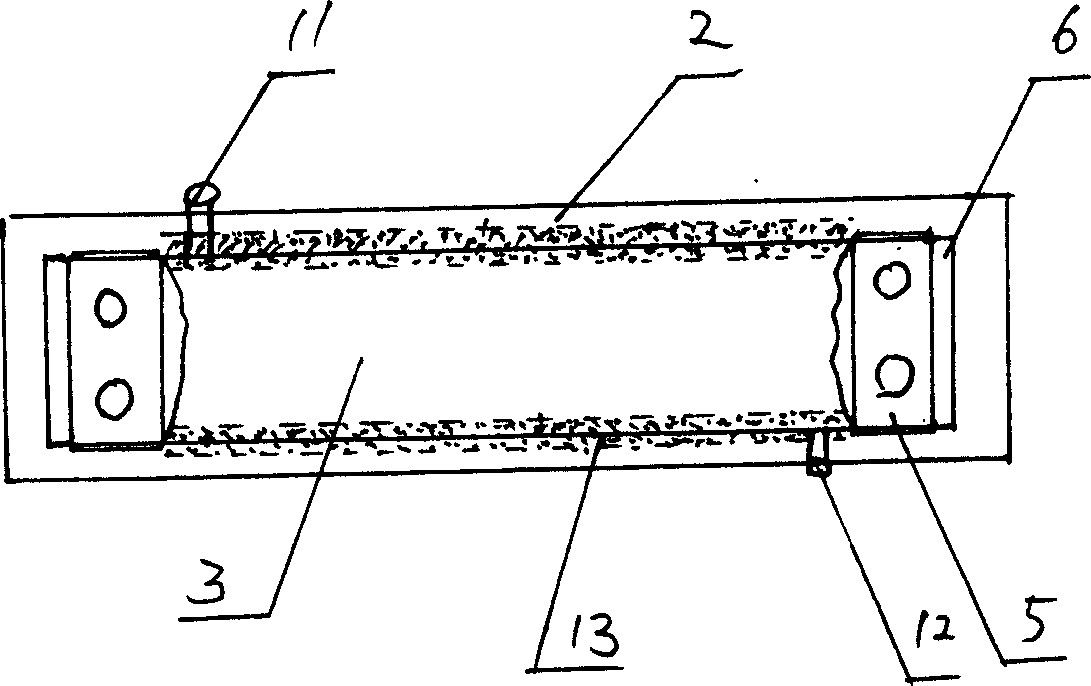

[0013] A method of using high-strength fiber cloth to reinforce components. First, the end of the high-strength fiber cloth 3 is bypassed by a steel roller 6 and then folded back. 1 is fixed at the end of the reinforced member 2. The high-strength fiber cloth 3 forms an end pan head at the steel roller 6 to improve the anchoring effect of the fiber cloth 3 at the end. Then the transverse tension is carried out by the transverse tension device 4 arranged between the two anchor ends. The bonding layer can be coated on the surface of the component 2 first, and the anchoring and tensioning are carried out before the glue of the bonding layer is solidified. It is also possible to seal the edge of the fiber cloth 3 with the component 2 with an adhesive tape 13 after the anchoring and tensioning are completed, and leave a glue injection hole 12 at one end, and leave a vent hole 11 at the other end, through the glue injection hole 12 to Structural glue is poured between the fiber cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com