Paper cup online collecting and automatic packaging device

A technology for automatic packaging and paper cups, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult adjustment of chutes, complicated operations, functional limitations, etc., and achieve the effect of reducing jamming and efficient transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

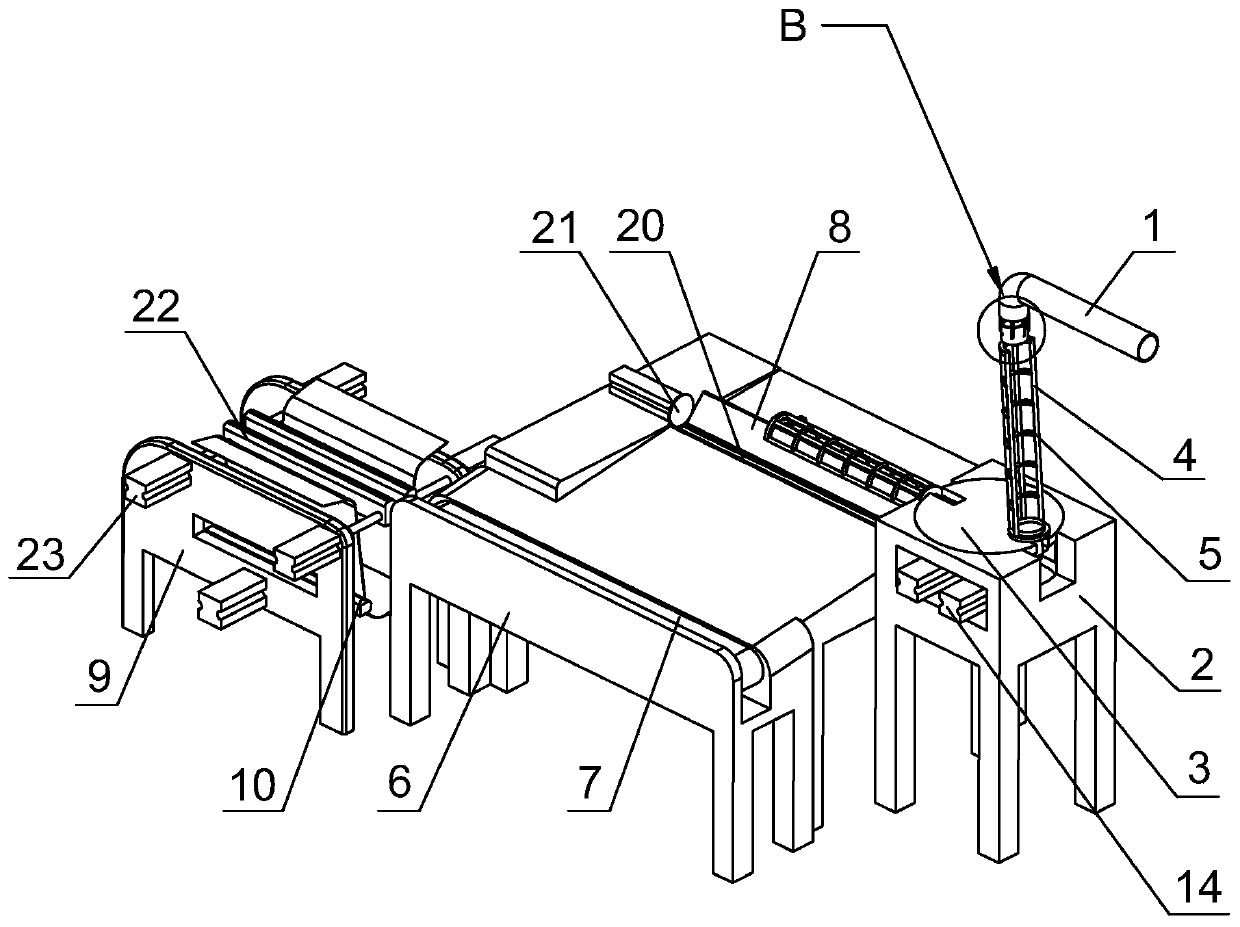

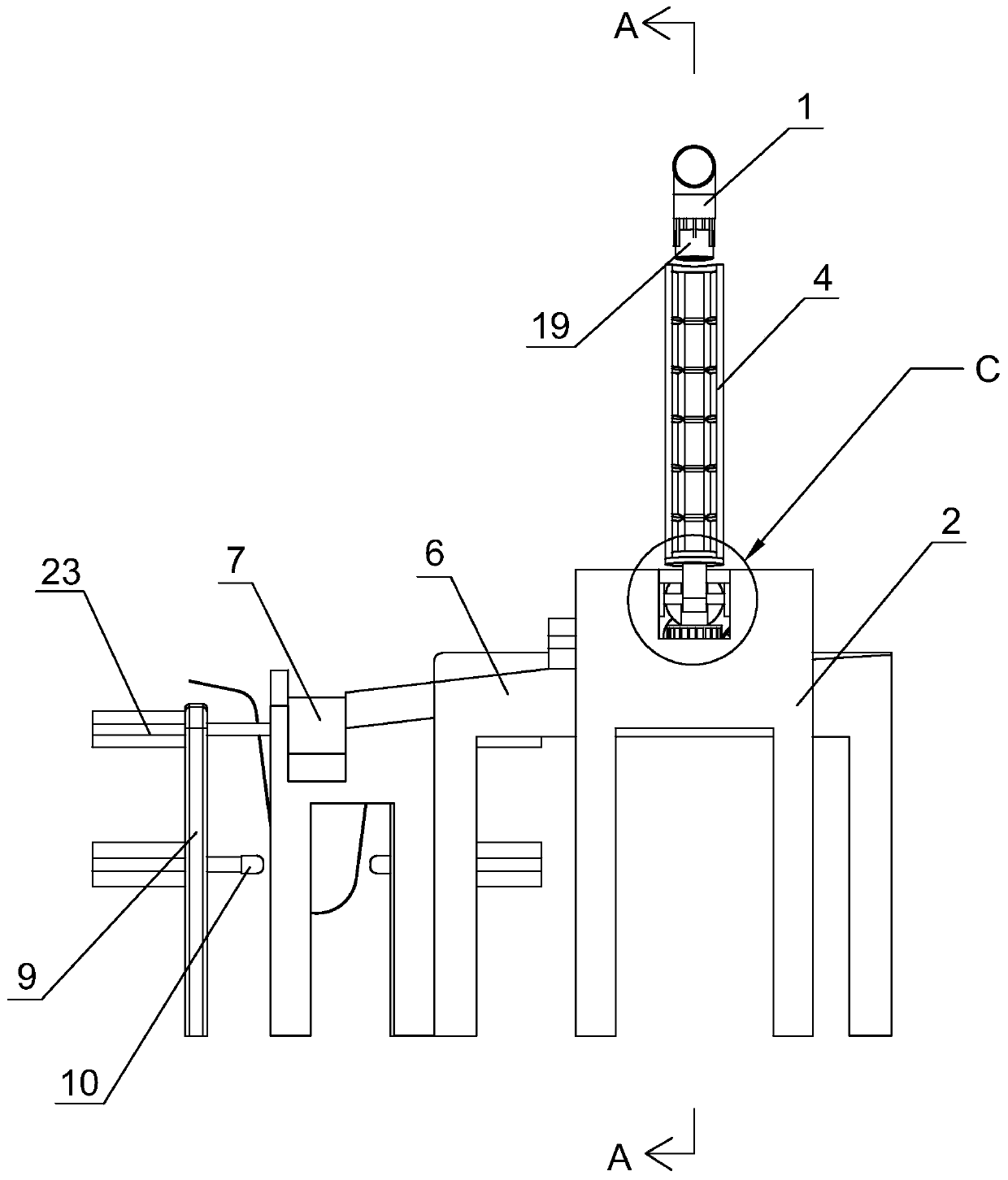

[0040]The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] refer to figure 1 , is an online collection and automatic packaging device for paper cups disclosed in the present invention, including a glass conduit 1 for outputting finished paper cups, a frame 2, a sorting mechanism, a transfer mechanism, and a bagging mechanism. One end of the glass conduit 1 extends to the In the paper cup production workshop, the other end extends to the position where the frame 2 is located. A negative pressure fan is fixed outside the glass conduit 1 to guide the finished paper cups into the glass conduit 1 and move to the side where the frame 2 is located. The inside of the glass conduit 1 is drawn into a negative pressure by a negative pressure fan, and the finished paper cup is moved to the position where the frame 2 is located by the suction force.

[0042] The sorting mechanism includes a sorting carousel 3 and two cup c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com