Water conservancy and hydropower dam water inlet floating object cleaning device

A water conservancy, hydropower, and cleaning device technology, which is applied in water conservancy projects, solid waste removal, artificial waterways, etc., can solve problems such as difficult cleaning by staff, excessive accumulation of garbage at water inlets, etc., to achieve convenient handling and processing, convenient follow-up processing, The effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

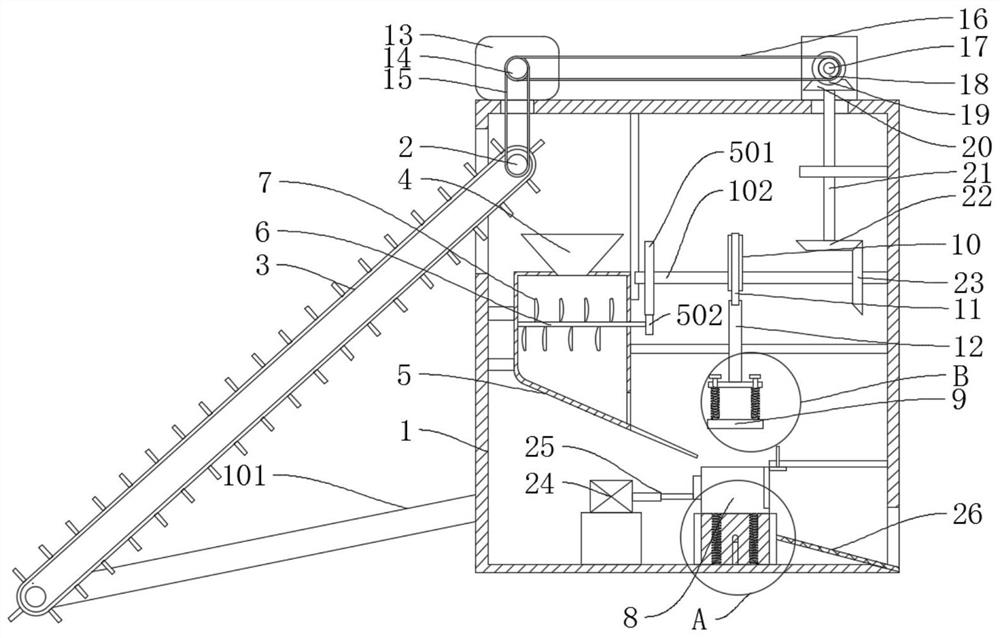

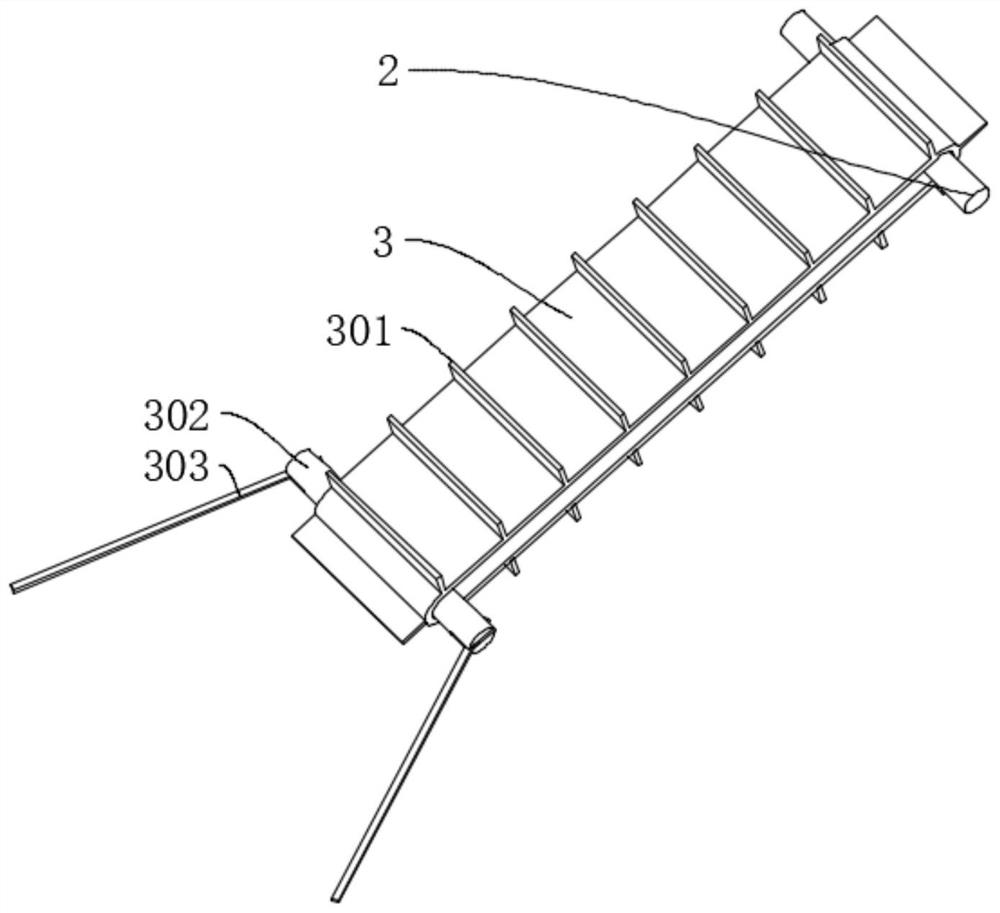

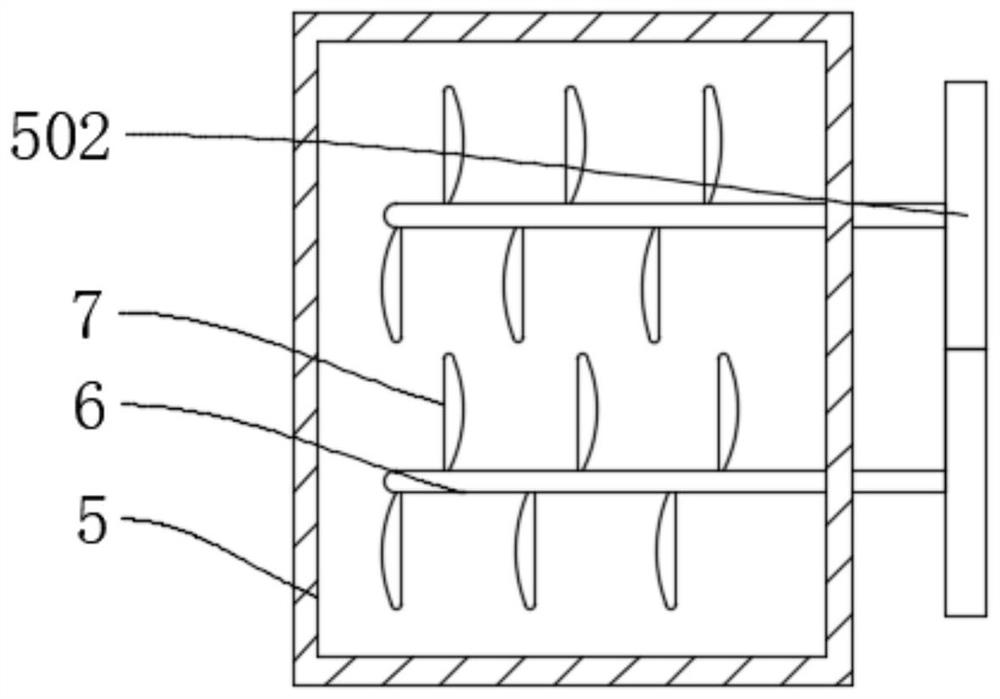

[0030] refer to figure 1 , figure 2 , image 3 , a water conservancy and hydropower dam water inlet floating debris cleaning device, including a box body 1, a transmission mechanism, a crushing mechanism, and an extrusion mechanism, the transmission mechanism is rotatably connected to the box body 1, and the crushing mechanism and the extrusion mechanism are fixedly connected to the box body 1, a drive mechanism is fixedly connected to the box body 1, the drive mechanism is connected to the transmission mechanism in rotation, and the drive mechanism is connected to the crushing mechanism and the extrusion mechanism in rotation through the transmission mechanism.

[0031] The driving mechanism includes a motor 13, a driving wheel 14, a first transmission belt 15 and a second transmission belt 16, the motor 13 is fixedly connected to the casing 1, the driving wheel 14 is fixedly connected to the output end of the motor 13, the first transmission belt 15 and the second transmis...

Embodiment 2

[0042] refer to figure 1 , Figure 4 , Figure 5 , Image 6 , a water conservancy and hydropower dam water inlet floating debris cleaning device, including a box body 1, a transmission mechanism, a crushing mechanism, and an extrusion mechanism, the transmission mechanism is rotatably connected to the box body 1, and the crushing mechanism and the extrusion mechanism are fixedly connected to the box body 1, a drive mechanism is fixedly connected to the box body 1, the drive mechanism is connected to the transmission mechanism in rotation, and the drive mechanism is connected to the crushing mechanism and the extrusion mechanism in rotation through the transmission mechanism.

[0043] The driving mechanism includes a motor 13, a driving wheel 14, a first transmission belt 15 and a second transmission belt 16, the motor 13 is fixedly connected to the casing 1, the driving wheel 14 is fixedly connected to the output end of the motor 13, the first transmission belt 15 and the se...

Embodiment 3

[0054] refer to figure 1 , a water conservancy and hydropower dam water inlet floating debris cleaning device, including a box body 1, a transmission mechanism, a crushing mechanism, and an extrusion mechanism, the transmission mechanism is rotatably connected to the box body 1, and the crushing mechanism and the extrusion mechanism are fixedly connected to the box body 1, a drive mechanism is fixedly connected to the box body 1, the drive mechanism is connected to the transmission mechanism in rotation, and the drive mechanism is connected to the crushing mechanism and the extrusion mechanism in rotation through the transmission mechanism.

[0055] The driving mechanism includes a motor 13, a driving wheel 14, a first transmission belt 15 and a second transmission belt 16, the motor 13 is fixedly connected to the casing 1, the driving wheel 14 is fixedly connected to the output end of the motor 13, the first transmission belt 15 and the second transmission belt 16 Both are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com