Plate type fractionation tower

A fractionation tower and plate type technology, applied in the field of fractionation towers, can solve the problems of poor tensile performance of metal valve sheets, valve sheet falling off, valve sheet rusting, etc., to achieve good corrosion resistance, prevent disconnection, and good insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

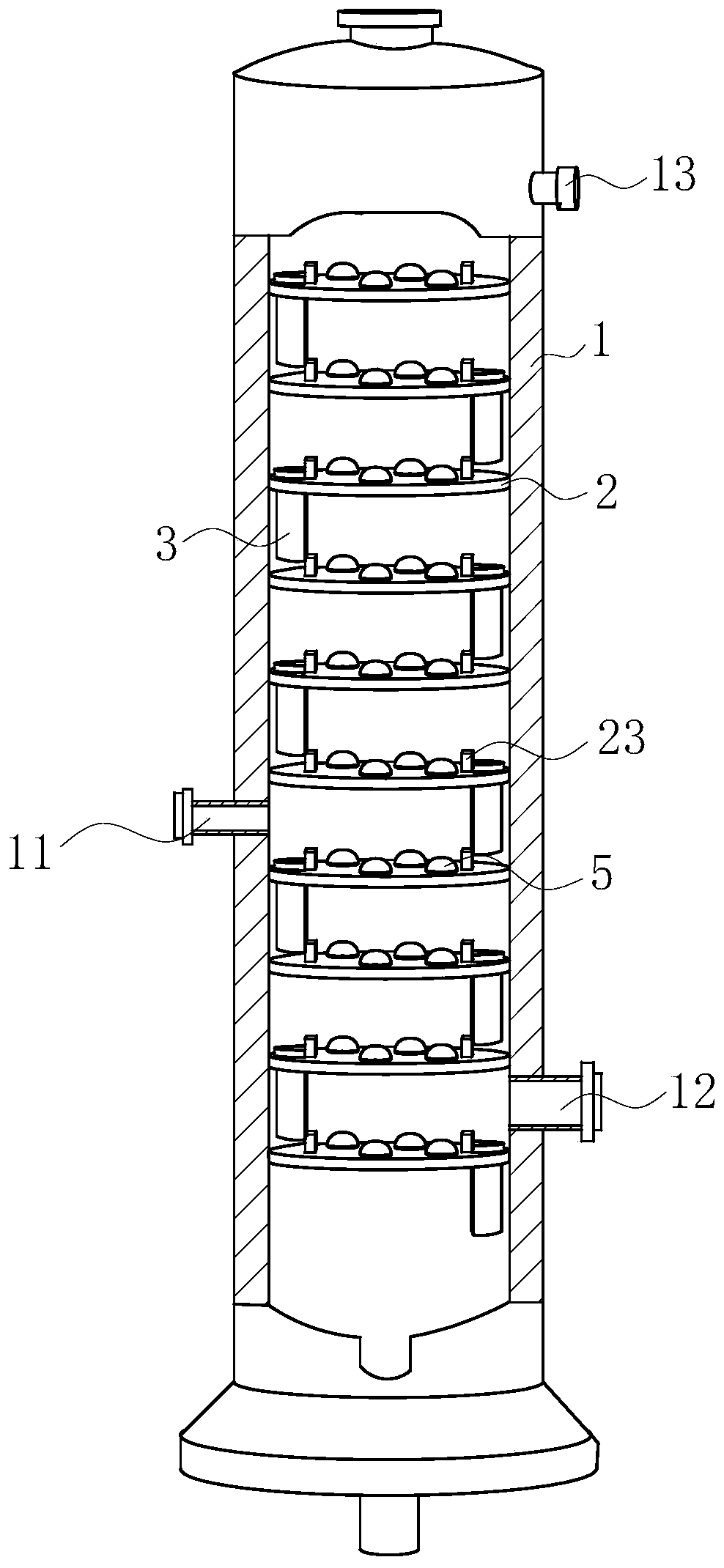

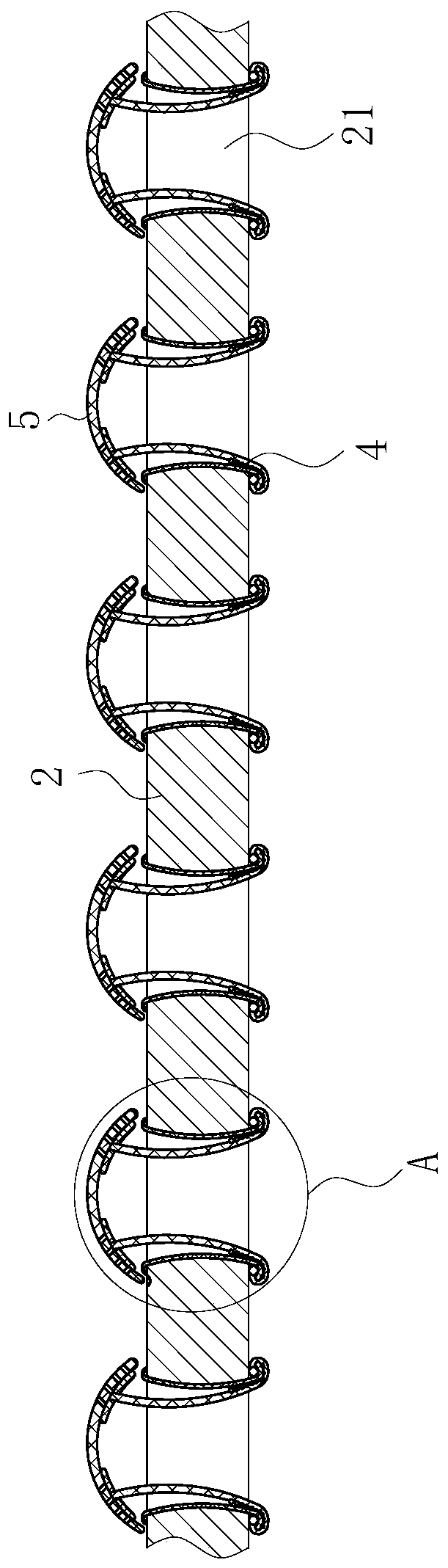

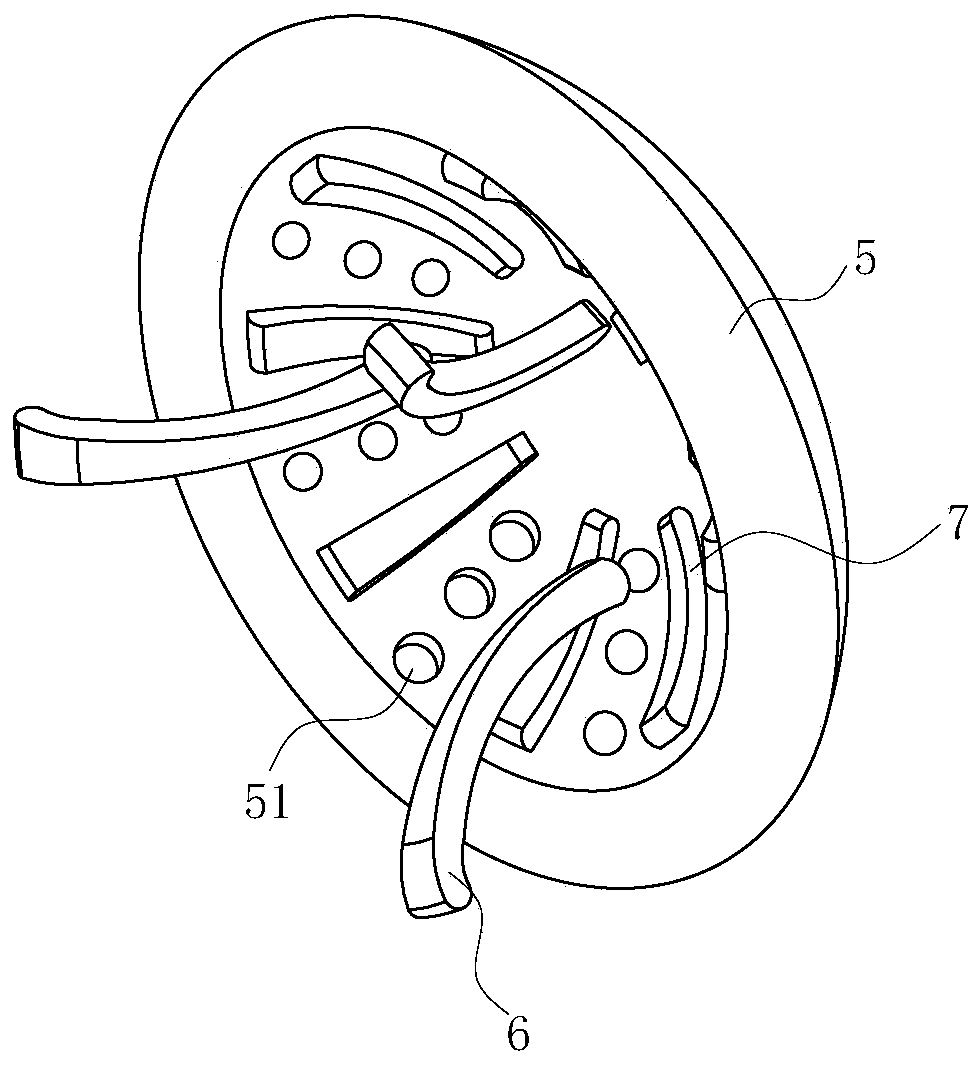

[0022] use Figure 1-Figure 5 A plate-type fractionation column according to an embodiment of the present invention will be described below.

[0023] like Figure 1-Figure 5As shown, a plate type fractionation tower according to the present invention includes a tower body 1 and a tower plate 2; one side of the tower body 1 is provided with a feed port 11, and the other side of the tower body 1 is provided with an air inlet port 12 and return port 13, and the feed port 11 is located between the air inlet 12 and the return port 13; the column plate 2 is evenly installed inside the tower body 1, and the upper surface of the column plate 2 is provided with an overflow weir 23, And the side of the overflow weir 23 is installed with a downcomer 3; the downcomer 3 between the adjacent two adjacent trays 2 is dislocated; the tray 2 is evenly provided with overflow holes 21, and the overflow An elastic riser 4 is inserted into the hole 21, and the bottom end of the elastic riser 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com