Special clamp and clamp group for serpentine laying of large-section cables and laying method

A special fixture and large cross-section technology, applied in the direction of electrical components, can solve problems such as mechanical damage to cables, and achieve the effects of reducing mechanical damage, high laying efficiency, and reducing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

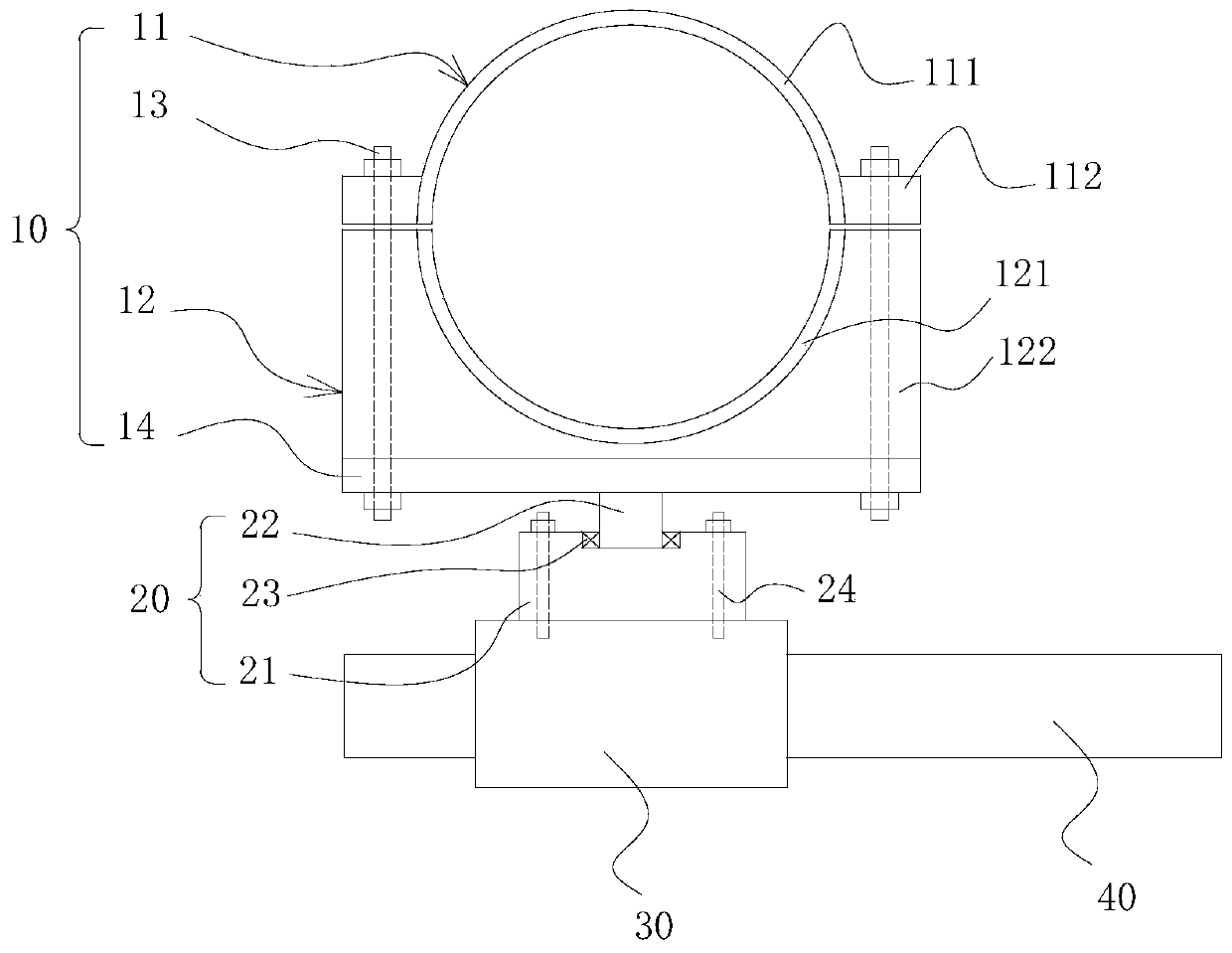

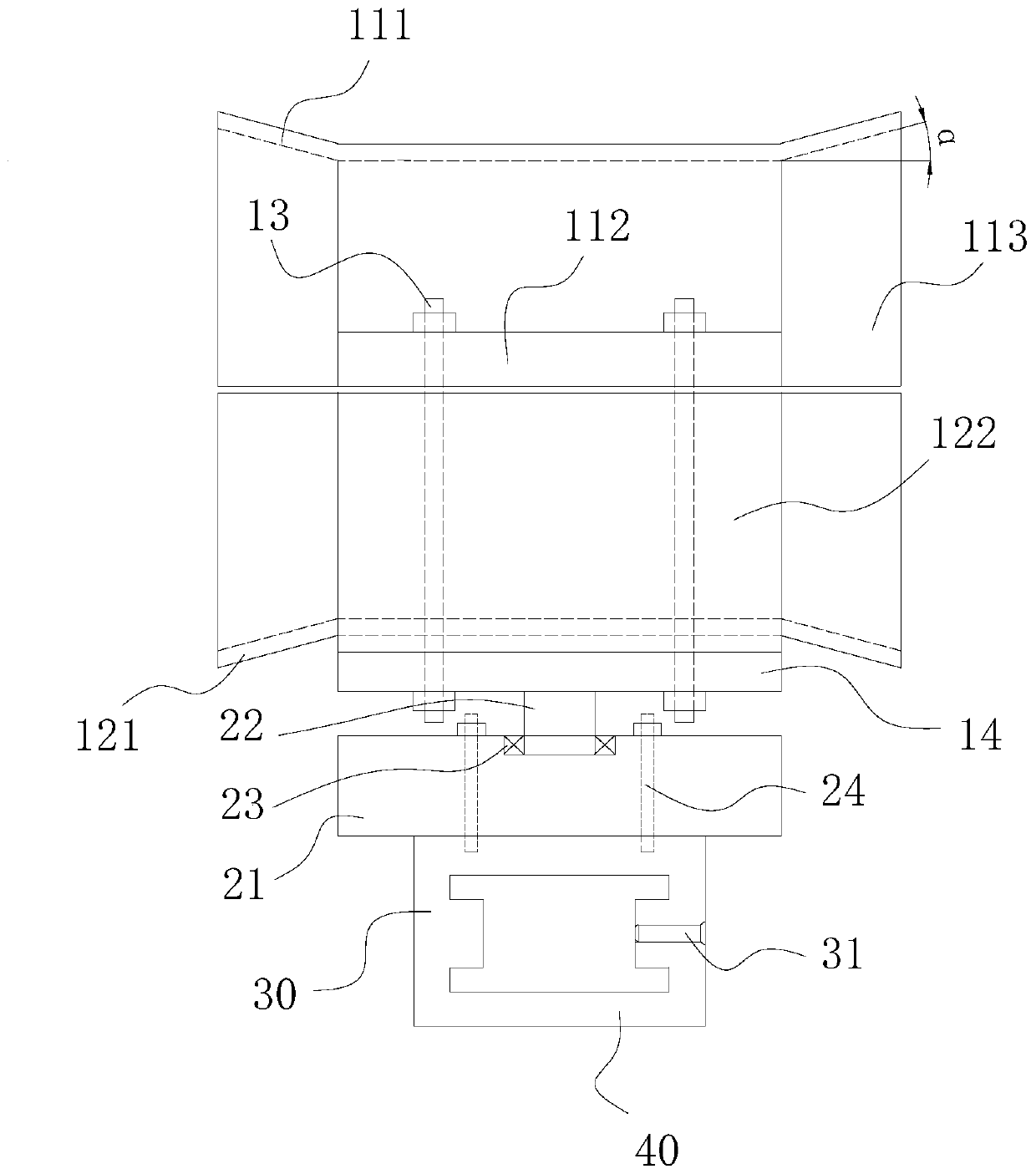

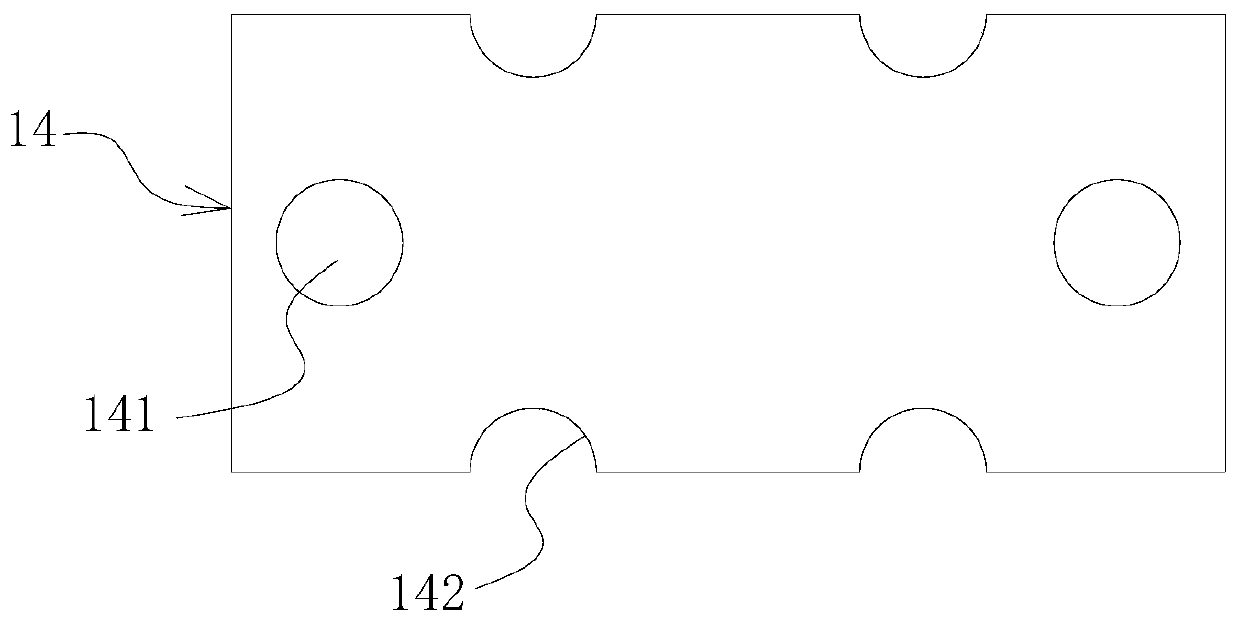

[0032] refer to Figure 1 ~ Figure 3 , the present invention provides a special fixture for serpentine laying of large cross-section cables, including a clamp body 10, a swivel base 20, a slider 30 and a guide rail 40; the clamp body 10 includes a connecting plate 14, a lower clamp body 12, an upper clamp body 11 and connecting Bolt 13, the lower clip body 12 includes a clamp seat 122 and a lower hoop, the lower hoop is welded on the clip seat 122, the upper clip body 11 includes an upper hoop, and the two ends of the upper hoop are provided with ears 112; the upper hoop It includes an upper arc-shaped plate 111, and the lower hoop includes a lower arc-shaped plate 121. After the upper and lower arc-shaped plates are closed together, a cylinder is formed. The inner diameter of the cylinder is adapted to the outer diameter of the cable, and the two ends of the cylinder face Open outward to form a bell mouth 113; the upper and lower hoops are held together by the connecting bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com