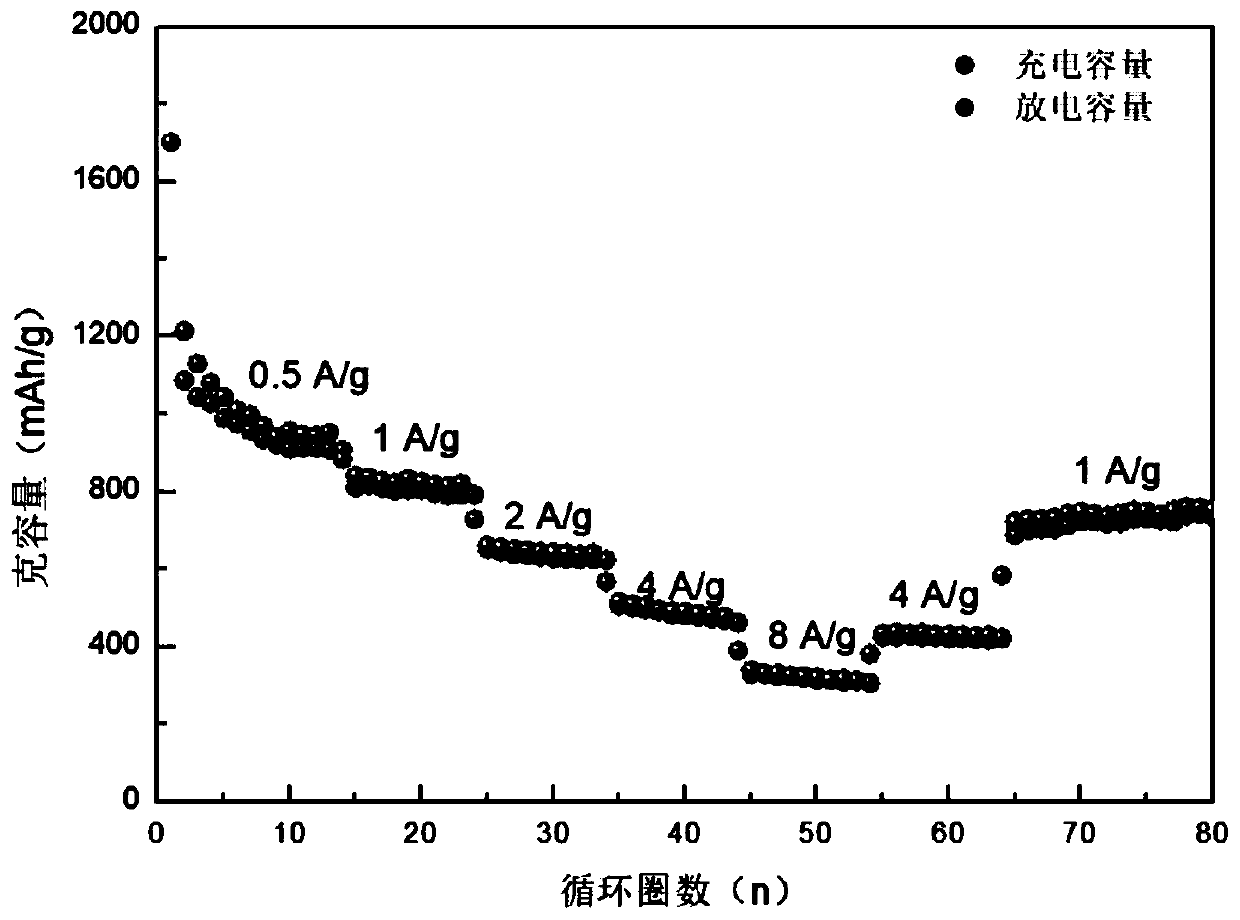

Electrostatic self-assembly three-dimensional flower-like cobalt disulfide/MXene composite material and preparation method and application thereof

An electrostatic self-assembly, three-dimensional flower-like technology, applied in nanotechnology, electrochemical generators, circuits, etc. for materials and surface science, to achieve high specific capacity, prevent collapse, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Mix 5mmol CoSO 4 ·7H 2 O and 10mmol Na 2 Dissolve S in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0035] 2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0036] 3. Pour the solution C described in step 2 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it at 150°C for 36 hours, then carry out suction filtration after cooling in the furnace, and obtain solid D after drying;

[0037] 4. Dilute 4ml of 20wt.% polydiallyldimethylammonium chloride (PDDA) solution with 100mL of deionized water, put 200mg of solid D obtained in step 3 into it and stir for a period of time, and obtain solid E;

[0038] 5. Weigh the aqueous solution containing 50mg of MXene, add 100mL of deionized water to dilute, put 200mg of solid E obtained in step 4 into it, stir it thoroughly and let it stand for 24 hou...

Embodiment 2

[0042] 1. Add 3mmol CoCl 2 ·6H 2 0 and 3mmol TAA (thioacetamide) were dissolved in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0043] 2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0044] 3. Pour the solution C described in step 2 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it at 150°C for 36 hours, then carry out suction filtration after cooling in the furnace, and obtain solid D after drying;

[0045] 4. Dilute 4ml of 20wt.% polydiallyldimethylammonium chloride (PDDA) solution with 100mL of deionized water, put 200mg of solid D obtained in step 3 into it and stir for a period of time, and obtain solid E;

[0046] 5. Weigh the aqueous solution containing 50mg of MXene, add 100mL of deionized water to dilute, put 200mg of solid E obtained in step 4 into it, stir it thoroughly and let ...

Embodiment 3

[0049] 1. Add 3mmol CoCl 2 ·6H 2 0 and 3mmol L-cysteine were dissolved in 40mL deionized water respectively to obtain pink A solution and B solution;

[0050] 2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0051] 3. Pour the solution C described in step 2 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it at 280°C for 36 hours, then carry out suction filtration after cooling in the furnace, and obtain solid D after drying;

[0052] 4. Dilute 4ml of 25wt.% polydiallyldimethylammonium chloride (PDDA) solution with 100mL of deionized water, put 200mg of solid D obtained in step 3 into it and stir for a period of time, and obtain solid E;

[0053] 5. Weigh the aqueous solution containing 5mg of MXene, add 100mL of deionized water to dilute, put 200mg of solid E obtained in step 4 into it, stir it thoroughly and let it stand for 35h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com