Clamping device for printed circuit board detection

A technology for printed circuit boards and clamping devices, which is applied in the directions of measuring devices, measuring device housings, and parts of electrical measuring instruments, etc., to achieve the effects of improving detection efficiency, high versatility, and maintaining flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as Figure 4 As shown, a clamping device for printed circuit board detection, the device includes a clamping mobile support plate 50, a front and rear moving support plate 51, a front and rear moving electric cylinder 52, a front and rear moving slide rail 53, a left and right moving support plate 54, Left and right moving electric cylinder 55 , left and right moving slide rail 56 , clamping moving plate 58 , and three clamping assemblies 59 ; The left part of moving back and forth support plate 51 is arranged on the moving part of moving electric cylinder 52 forward and backward, and the right part of moving back and forth supporting plate 51 is arranged on the slide rail 53 of front and rear movement, drives back and forth moving support plate 51 by moving electric cylinder 52 forward and backward. The front and rear moving slide rails 53 move forward and backward; the front portion of the left and right moving support plate 54 is arranged on the front portion of...

Embodiment 2

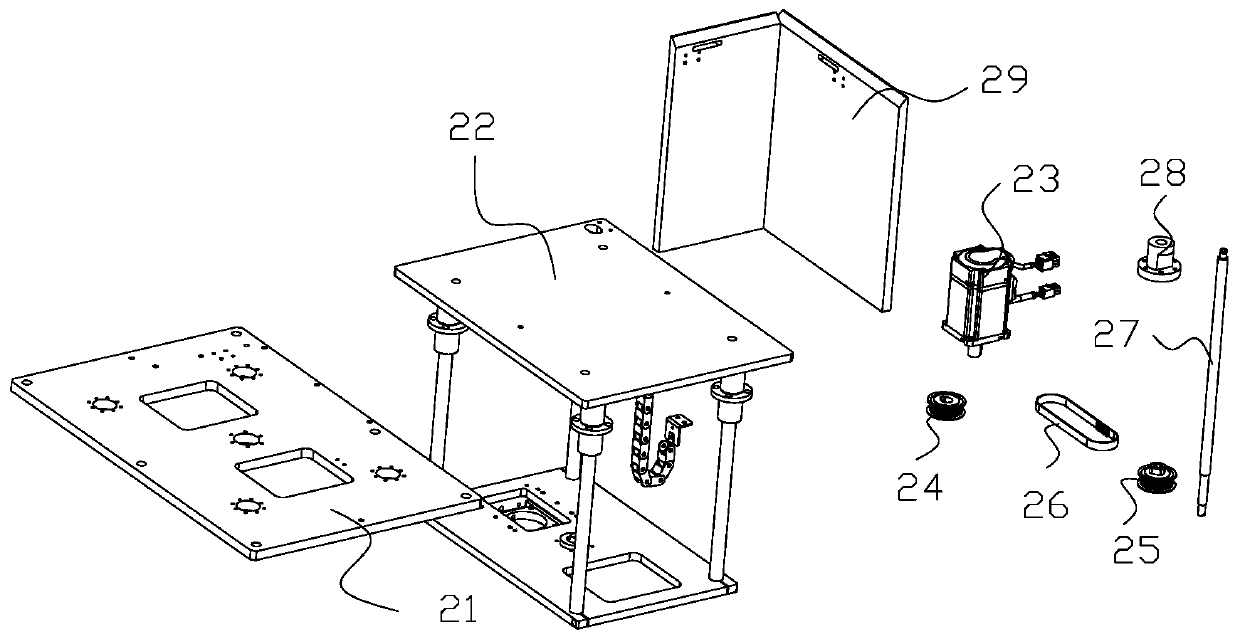

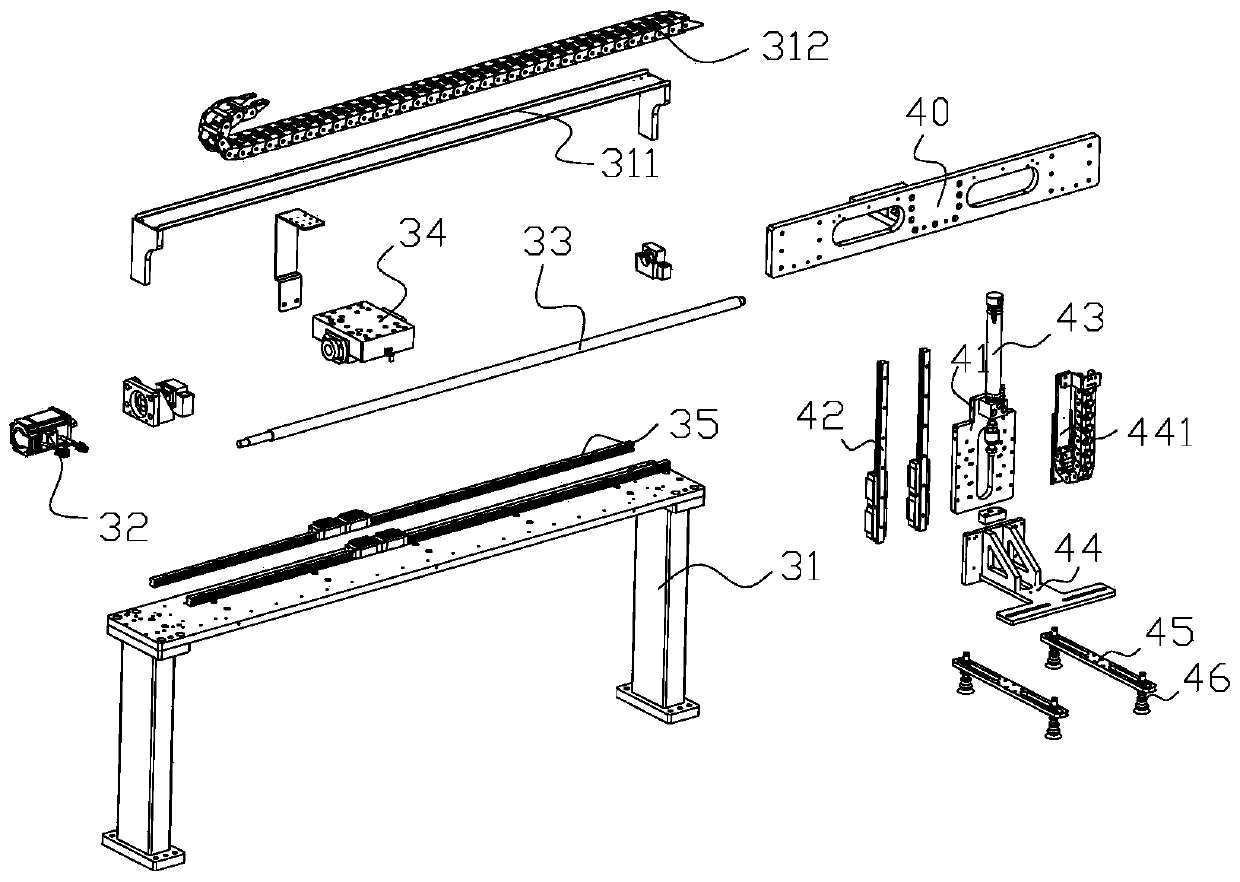

[0033] Such as figure 1 As shown, an automatic detection equipment for printed circuit boards includes a frame 1, a feeding device 2, a horizontal moving device 3, a retrieving device 4, a clamping moving device 5, a detection device 6 and a feeding device 7; the feeding device 2 is arranged at the feeding end of the frame 1, and the feeding device is used to feed the printed circuit board; the horizontal moving device 3 is arranged at the rear of the frame 1; the reclaiming device 4 is arranged on the On the horizontal moving device 3, the retrieving device 4 is used to clamp the printed circuit board, and the horizontal moving device 3 drives the printed circuit board on the reclaiming device 4 to move horizontally, and the feeding and unloading are completed through the retrieving device 4; The clamping mobile device 5 is arranged in the middle of the frame 1; the clamping mobile device 5 is used to clamp the printed circuit board and drive the printed circuit board to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com