An electric kettle hot water cooling system

An electric kettle and hot water technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of long waiting time, low cooling efficiency, low heat dissipation efficiency, etc., and achieve low cost and structural Simple and effective in improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

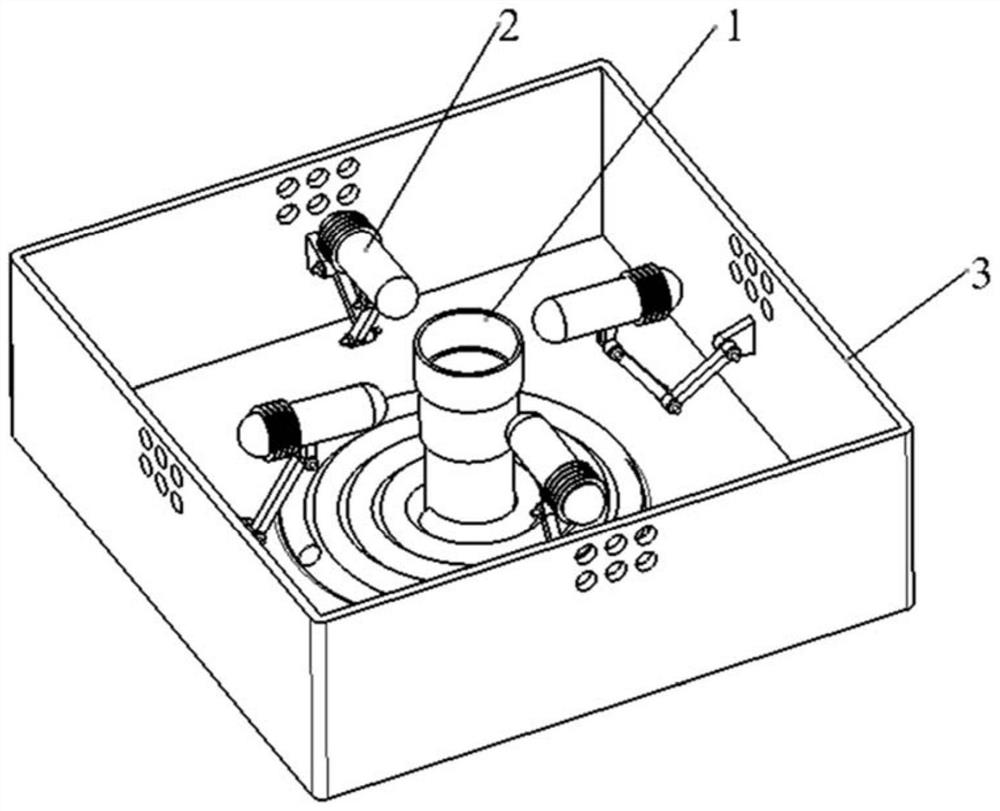

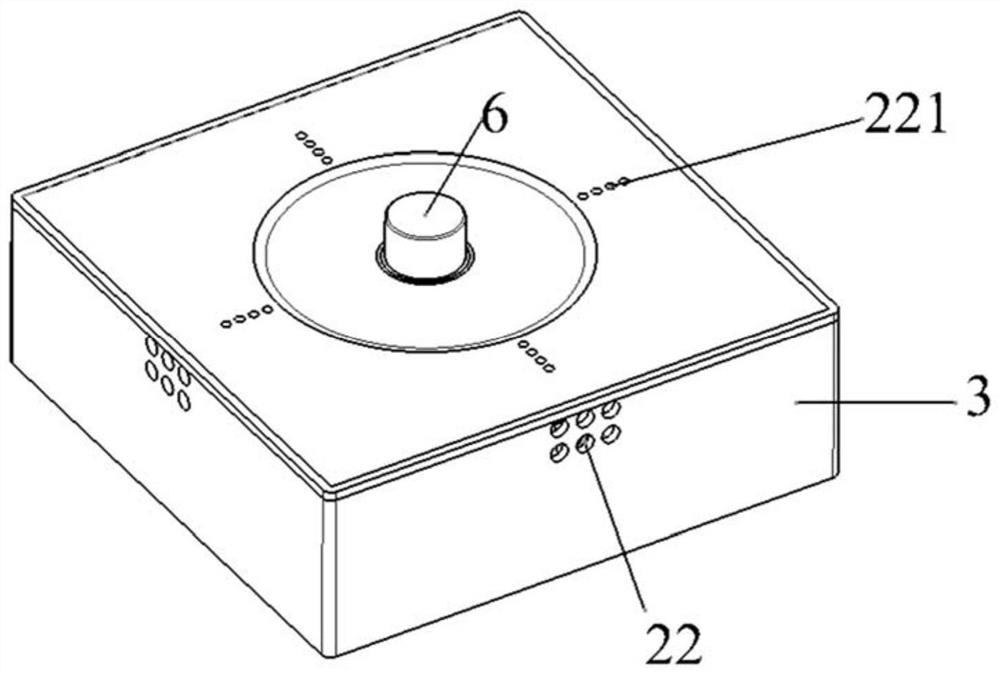

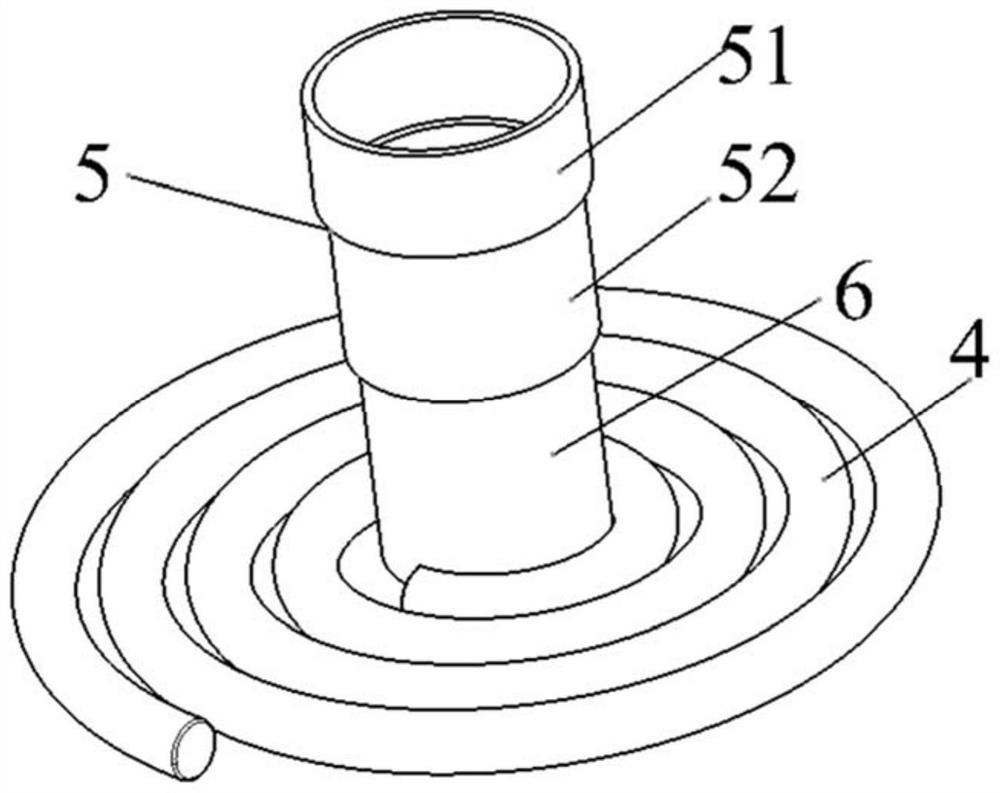

[0029] Embodiment 1: A hot water cooling system for an electric kettle, including a heating assembly, a cooling assembly, and a casing. The casing 3 includes a base and a top plate. The upper top of the top plate is provided with a middle hole 23, and the heating assembly is arranged on the The middle part of the base, the heating assembly includes a resistance wire 4, an electric push rod 5 and a heating column 6, the resistance wire 4 is coaxially arranged with the heating column, and a number of cooling tubes are provided on the peripheral side of the heating column 6 Components 2, each of the cooling components 2 includes a heat pipe 7, a fixed hinge 8, a moving crank 9, a rocking rod 10 and a connecting rod 11, and the heat pipe 7 is provided with a connecting rod 11 on the side facing the base, and the connecting rod 11 Rod 11 is hinged with one end of described rocking bar 10, and the other end of described rocking bar 10 is hinged with described moving crank 9, and the ...

Embodiment 2

[0030] Embodiment 2: A hot water cooling system for an electric kettle, including a heating assembly, a cooling assembly, and a casing. The casing 3 includes a base and a top plate. The upper top of the top plate is provided with a middle hole 23, and the heating assembly is arranged on the The middle part of the base, the heating assembly includes a resistance wire 4, an electric push rod 5 and a heating column 6, the resistance wire 4 is coaxially arranged with the heating column, and a number of cooling tubes are provided on the peripheral side of the heating column 6 Components 2, each of the cooling components 2 includes a heat pipe 7, a fixed hinge 8, a moving crank 9, a rocking rod 10 and a connecting rod 11, and the heat pipe 7 is provided with a connecting rod 11 on the side facing the base, and the connecting rod 11 Rod 11 is hinged with one end of said rocking lever 10, the other end of said rocking lever 10 is hinged with said moving crank 9, the other end of said m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com