High-pressure-water cavitation rock breaking TBM and construction method thereof

A high-pressure water and high-pressure water pump technology, used in earth-moving drilling, mining equipment, tunnels, etc., to achieve the effect of reducing total thrust, reducing vibration, and reducing central belt conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

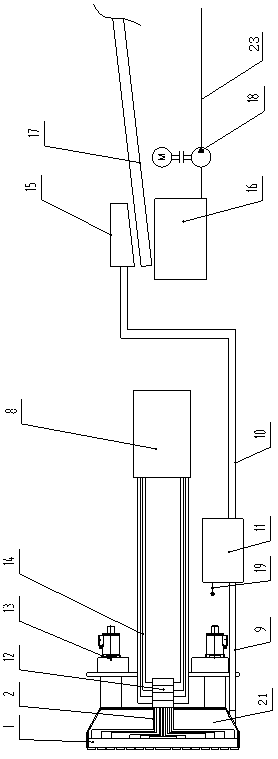

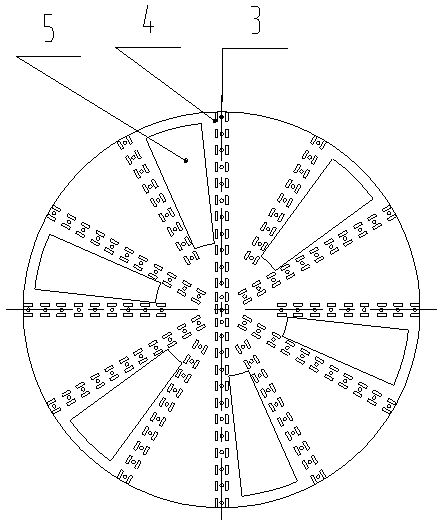

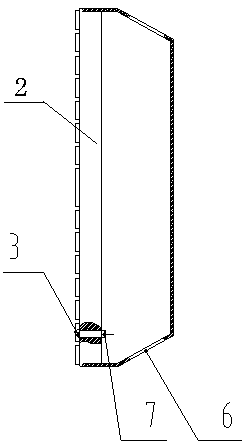

[0026] Example 1, such as figure 1 As shown, a high-pressure water cavitation rock-breaking TBM includes a main machine 1, a cutter head 2 is provided at the front end of the main machine 1, and several pulse cavitation nozzles 3 are arranged on the cutter head 2, and the pulse cavitation nozzles can be covered with The front end of the cutter head is suitable, and the pulse cavitation nozzle 3 is connected to the high-pressure water system. The high-pressure water system leads the high-pressure water to the pulse cavitation nozzle to form a cavitation water jet, which instantly generates high pressure and micro jets to directly erode the broken rock , to achieve full-section pure water rock breaking. The rear of the cutter head 2 is connected with a vacuum sewage system, which uses the jet vacuum sewage device as a power source to discharge sludge and water. The vacuum sewage system has high sewage discharge efficiency and compact structure. The installation in the center pr...

Embodiment 2

[0028] Example 2, such as figure 1 As shown, a high-pressure water cavitation rock-breaking TBM, the high-pressure water system includes a high-pressure water pump set 8, the high-pressure water pump set 8 is provided with a first high-pressure pipeline 14, and the first high-pressure pipeline 14 passes through a multi-channel high-pressure rotary assembly 12 is connected to the high-pressure pipeline 2 of the cutter head. Under the action of the high-pressure water pump group, the high-pressure water enters the multi-channel high-pressure rotary assembly 12 through the first high-pressure pipeline. The multi-channel high-pressure rotary assembly is a kind of rotary joint. The high-pressure rotary center Used to deliver high pressure water to the rotating cutter head. One end of the cutterhead high-pressure pipeline 2 is rotatably connected to the multi-channel high-pressure rotary assembly 12 , and the other end is connected to the pulse cavitation nozzle 3 . The high-pressu...

Embodiment 3

[0030] Example 3, such as Figure 4 As shown, a high-pressure water cavitation rock-breaking TBM, the sewage pipeline 19 is provided with a filter and purification device 20, the filter and purification device 20 filters and purifies the sewage separated by the slag-water separation device 15, and the filter and purification device 20 A water outlet pipe 22 is provided, and a water pump is arranged on the water outlet pipe. The water outlet pipe 22 is connected with the high-pressure water pump group 8. Under the action of the water pump, the filtered and purified water enters the high-pressure water pump group, and then re-passes into the pulse cavitation nozzle to perform cavitation. The jet breaks rocks and realizes water circulation.

[0031] Other structures are the same as in Embodiment 2.

[0032] A construction method of high-pressure water cavitation rock-breaking TBM, comprising the following steps:

[0033] S1: Start the high-pressure water pump set and adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com