Non-pressure grouting method based on mine construction

A grouting and mine technology, applied in mining equipment, shaft equipment, shaft lining, etc., can solve the problems of broken surrounding rock, a small amount of water gushing, and poor quality of the shaft wall, so as to reduce the pressure of the shaft wall and ensure the quality of the shaft wall quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Wellbore pressureless grouting method

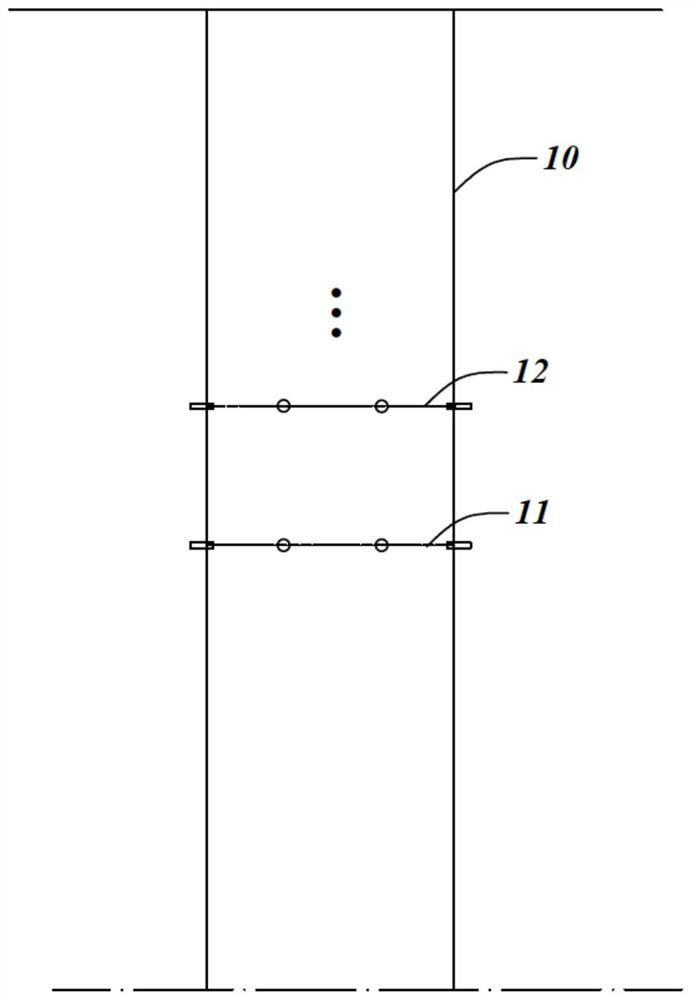

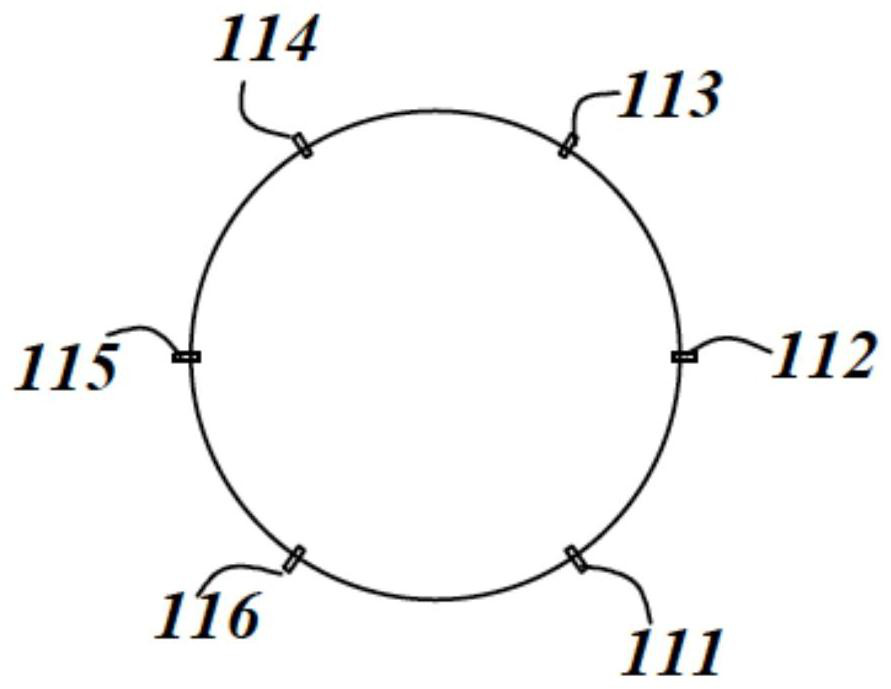

[0041] ginseng Figure 2a , 2b As shown, the wall of the wellbore 10 includes a first section 11, a second section 12 . . . in order from bottom to top at different levels, and several grouting holes are equally spaced on each section, as shown in the present embodiment. 2m, the first section 11 is provided with grouting holes 111, 112, 113, 114, 115 and 116 in sequence, the cross section of the first section 11 is circular, and the 6 grouting holes are evenly distributed along the circumference at equal intervals. The spacing of the grouting holes is 2m, and the setting of the grouting holes on the other sections is the same as that of the first section, and will not be repeated here. In addition, a gate valve is correspondingly installed on each grouting hole to control the opening or closing of the grouting hole.

[0042] The specific steps of the pressureless grouting method in this embodiment are as follows:

...

Embodiment 2

[0049] Example 2: Roadway pressureless grouting method

[0050] ginseng Figure 3a , 3b As shown, the shaft wall of the roadway 20 includes a first section 21, a second section 22... A section 21 is provided with grouting holes 211, 212, 213, 214, 215 and 116 in sequence, the grouting holes 211 and 216 are located at the same level, the grouting holes 212 and 215 are located at the same level, Located at the same level, the spacing of the six grouting holes on the first section 11 is 2m, and the setting of the grouting holes on the other sections is the same as that of the first section, which will not be repeated here. In addition, a gate valve is correspondingly installed on each grouting hole to control the opening or closing of the grouting hole.

[0051] When grouting the roadway, it is necessary to install all the orifice pipes of the grouting section first, and then seal the grouting by shotcrete or masonry.

[0052] The specific steps of the pressureless grouting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com