Method and a system for detecting rod pumped well polish rod suspension center dead point

A technology for pumping wells and detection methods, which is applied in the direction of measurement, drill pipe, drilling equipment, etc., can solve problems such as dead point drift, accuracy cannot be guaranteed, and affect displacement detection accuracy, so as to achieve high safety, improve monitoring capabilities, and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

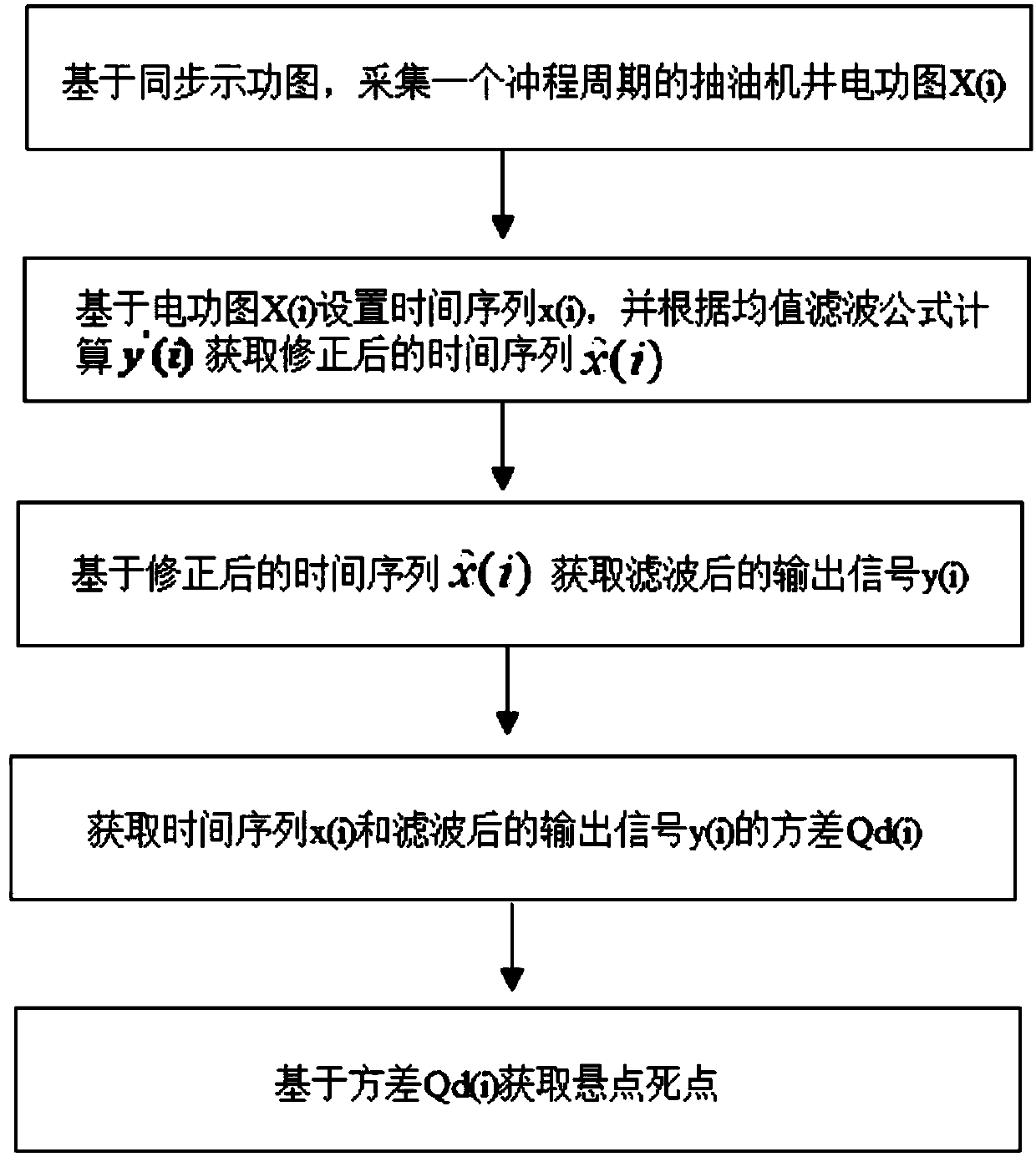

[0098] figure 1 A flow chart showing the steps of a method for detecting the dead center of a polished rod of a pumping unit according to an exemplary embodiment of the present invention.

[0099] like figure 1 As shown, the present embodiment provides a detection method for the dead point of the polished rod of the pumping unit, including:

[0100] Based on the synchronous dynamometer diagram, collect the electric power diagram X(i) of the pumping well for one stroke cycle;

[0101] Set the time series x(i) based on the electric power diagram X(i), and calculate y'(i) according to the mean filter formula to obtain the corrected time series

[0102] Based on the corrected time series Obtain the filtered output signal y(i);

[0103] Obtain the variance Qd(i) of the time series x(i) and the filtered output signal y(i);

[0104] Obtain the dead point of the suspension point based on the variance Qd(i).

[0105] Among them, the variance Qd(i) is:

[0106]

[0107] Fur...

Embodiment 2

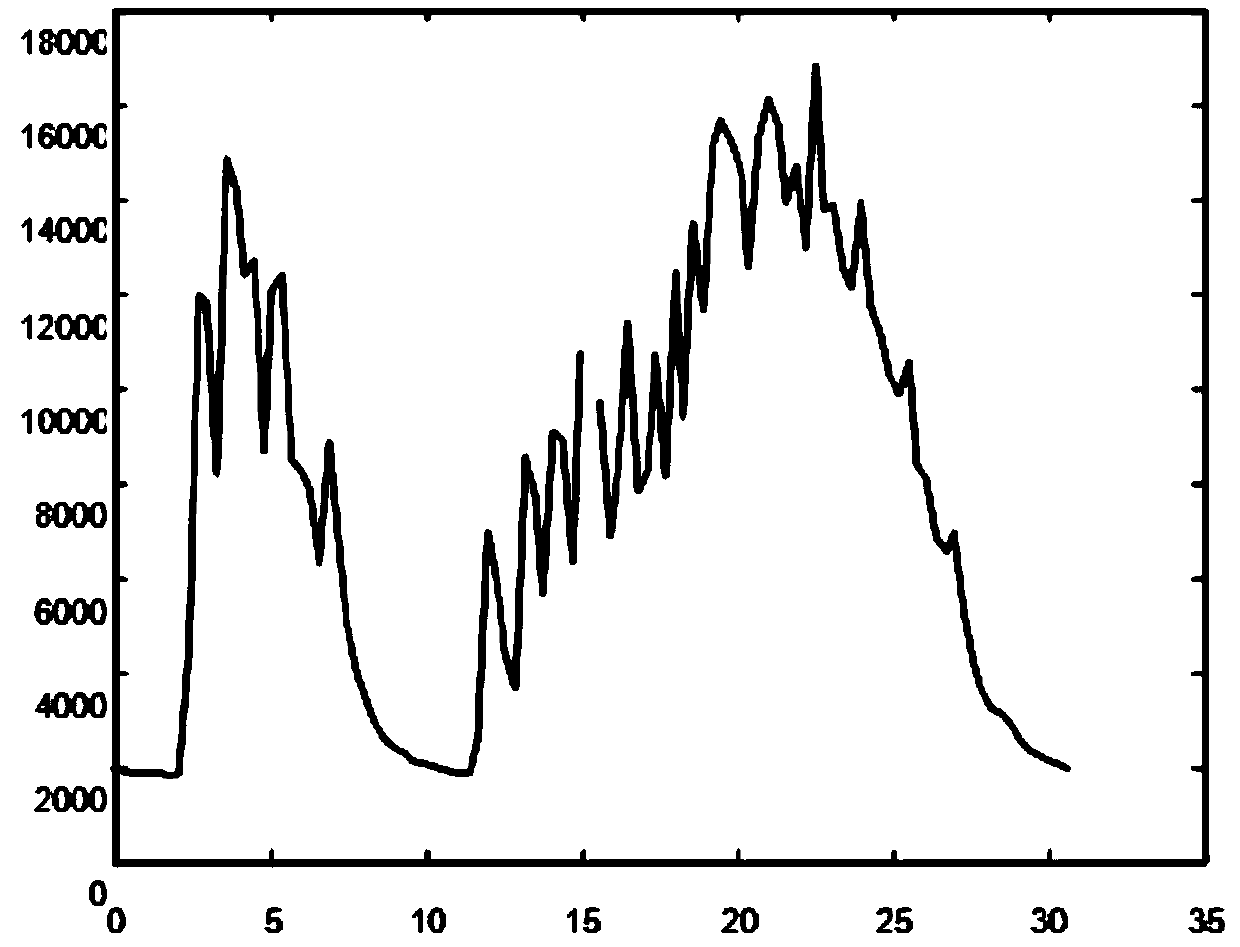

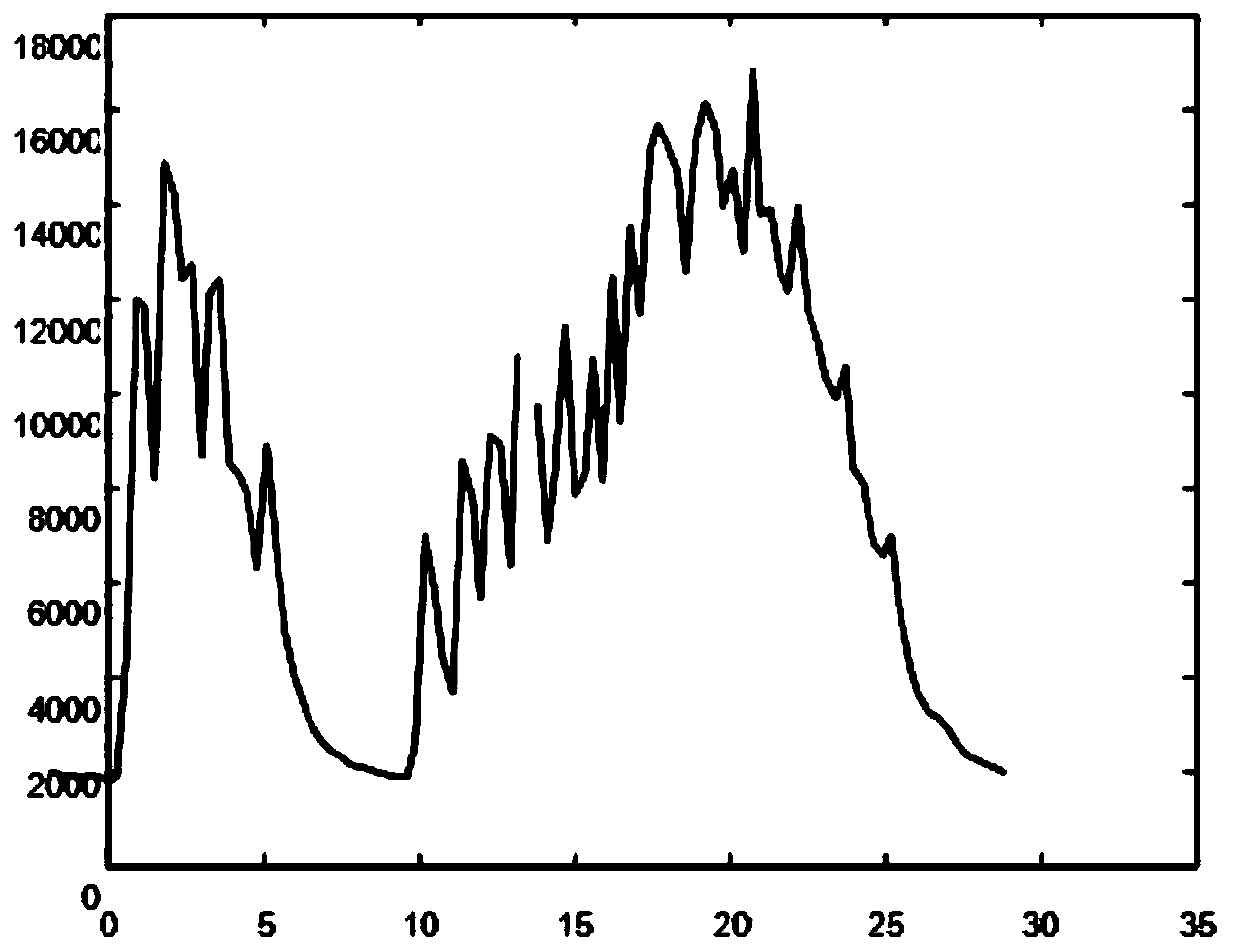

[0133] figure 2 It shows a periodic electric power diagram output synchronously with the indicator diagram of a pumping unit well according to an exemplary embodiment of the present invention. image 3 It shows a corrected cycle electric power diagram according to an exemplary embodiment of the present invention.

[0134] like figure 2 and image 3 As shown, the method of Example 1 is applied to the well number X109X102, and it can be seen that based on the synchronous dynamometer diagram acquisition of the pumping unit well cycle electric power diagram, the method detects that the electric power diagram collected by the well has a dead point lag, figure 2 The calculated liquid volume of the collection graph will lead to an increase in the judgment of the effective stroke, which will lead to a larger calculated liquid volume. The corrected electric power diagram is as follows: image 3 As shown, the obtained corrected cycle electric power diagram realizes the purpose of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com