Correcting device of transmission center of metering pump of spinning machine

A technology of calibration device and metering pump, which is applied in the direction of machine/engine, pump, mechanical equipment, etc., can solve the problems of non-concentricity of metering pump transmission, easy damage of metering pump, difficult measurement of concentricity, etc., to achieve simple structure design and reduce production. Cost, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

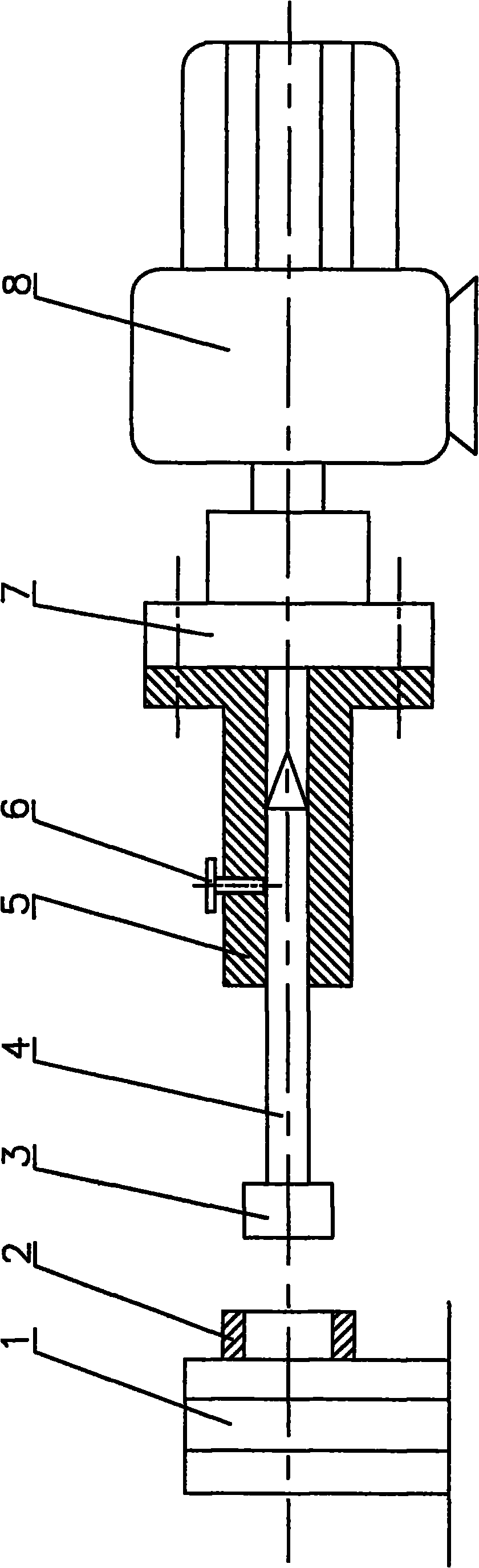

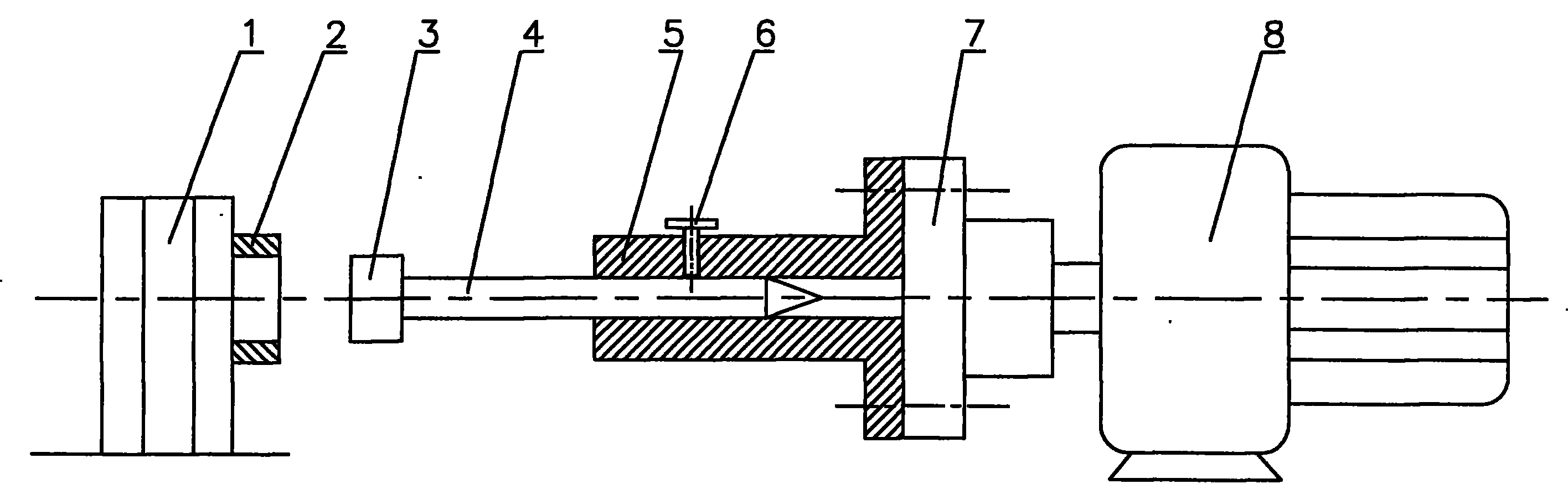

[0011] Below by non-limiting embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0012] As shown in the accompanying drawings, it is a schematic diagram of the present invention in practical application. The present invention includes a sleeve 5 with a central hole in the axial direction and a correction rod 4 that is passed through the central hole of the sleeve 5 and can slide axially. One end of the sleeve 5 has a coupling plate. The matching gap between the rod 4 and the center hole of the sleeve is preferably 0.03mm~0.04mm. The head end of the correction rod 4 has a correction head 3, which matches the shaft hole of the metering pump coupling 2. The correction rod The tail end of 4 is tapered to facilitate assembly. There is also a locking screw 6 on the sleeve 5, so that the correction rod 4 can be locked.

[0013] When the present invention is applied in practice, the connecting disk of the sleeve 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com