Three-dimensional carbon aeration electrode for efficiently producing hydrogen peroxide

A hydrogen peroxide and carbon electrode technology, applied in the field of environmental engineering, can solve the problems of complex reactor configuration, complex cathode preparation, and low oxygen utilization rate, and achieve strong hydraulic shock resistance, good mass transfer effect, and oxygen utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

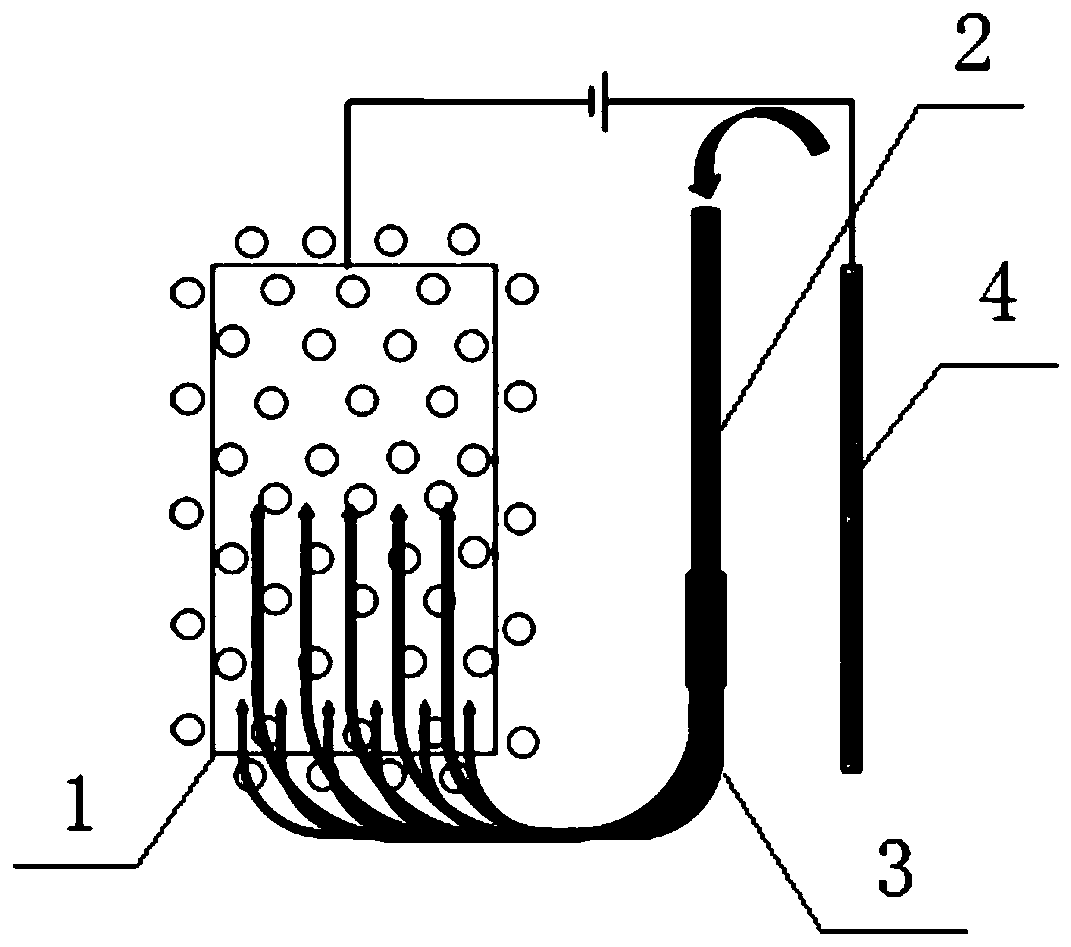

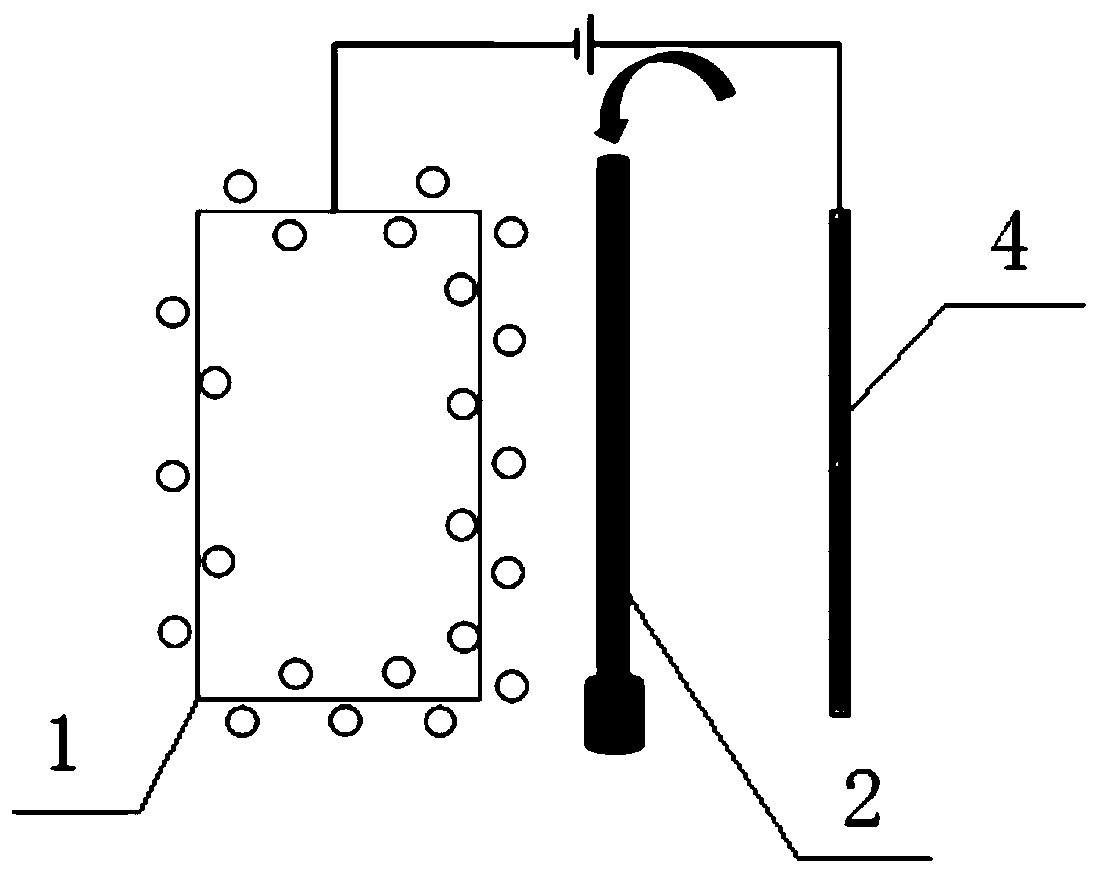

[0018] Specific Embodiment 1: In this embodiment, a three-dimensional carbon aeration electrode includes a three-dimensional carbon electrode 1 and several flexible tubes 3. The three-dimensional carbon electrode 1 is used as a cathode, and the three-dimensional carbon electrode 1 has a three-dimensional channel. One end of the tube 3 extends into the interior of the three-dimensional carbon electrode 1 and communicates with the three-dimensional channel.

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the three-dimensional carbon electrode 1 has a carbon cathode with a three-dimensional structure macroscopically, and the three-dimensional carbon electrode 1 is a graphite felt electrode, a carbon felt electrode, or an activated carbon fiber electrode. , Mesh glassy carbon electrode, graphite sponge electrode, carbon airgel electrode or foam carbon electrode.

[0020] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the three-dimensional carbon aeration electrode also includes a vent pipe 2 , and the vent pipe 2 communicates with the other ends of several hoses 3 .

[0022] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com