Nano diamond riding wheel bearing bush oil and preparation method thereof

A nano-diamond and support wheel shaft technology, applied in the field of lubricating oil, can solve the problems of increasing the number and time of maintenance, insufficient protection of bearing pads, and increased wear, so as to improve the extreme pressure and anti-wear performance and bearing capacity, and reduce the time and frequency of maintenance , Improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

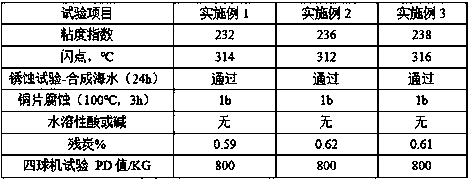

Examples

Embodiment 1

[0032] In the present embodiment, a kind of nano-diamond supporting wheel bearing pad oil is made up of following components by weight:

[0033] Metallocene PAO200C 29.5 parts;

[0034] 21 parts of alkyl naphthalene;

[0035] High-performance complex calcium sulfonate base grease 20 parts;

[0036] 8 parts of nano-diamond dispersions through lipophilic surface modification;

[0037] 1.0 parts of aromatic amine antioxidants;

[0038] 6.5 parts of polyisobutylene PIB1100;

[0039] 7 parts of hydrogenated styrene isoprene copolymer;

[0040] 3.6 parts of ashless composite extreme pressure antiwear agent;

[0041] 0.85 parts of multifunctional agent;

[0042] 8 parts of solid additives;

[0043] Among them, the lipophilic surface-modified nano-diamond dispersion is to uniformly disperse nano-diamonds with a particle size below 10nm in cyclohexane dicarboxylate, and disperse evenly through ultrasonic waves, and suspend within 2000h without precipitation. , the ratio of nano...

Embodiment 2

[0056] In the present embodiment, a kind of nano-diamond supporting wheel bearing pad oil is made up of following components by weight:

[0057] Metallocene PAO200C 30.5 parts;

[0058] 20 parts of alkyl naphthalene;

[0059] High-performance complex calcium sulfonate base grease 22 parts;

[0060] 9 parts of nano-diamond dispersions through lipophilic surface modification;

[0061] 1.1 parts of aromatic amine antioxidants;

[0062] 7 parts of polyisobutylene PIB1100;

[0063] 6.5 parts of hydrogenated styrene isoprene copolymer;

[0064] Ashless composite extreme pressure antiwear agent 3.8 parts;

[0065] 0.95 parts of multifunctional agent;

[0066] 8 parts of solid additives;

[0067] Among them, the lipophilic surface-modified nano-diamond dispersion is to uniformly disperse nano-diamonds with a particle size below 10nm in cyclohexane dicarboxylate, and disperse evenly through ultrasonic waves, and suspend within 2000h without precipitation. , the ratio of nano-diam...

Embodiment 3

[0080] In the present embodiment, a kind of nano-diamond supporting wheel bearing pad oil is made up of following components by weight:

[0081] Metallocene PAO200C 30 parts;

[0082] 19 parts of alkylnaphthalene;

[0083] High-performance complex calcium sulfonate base grease 21 parts;

[0084] 7 parts of nano-diamond dispersions through lipophilic surface modification;

[0085] 1.2 parts of aromatic amine antioxidants;

[0086] 7.5 parts of polyisobutylene PIB1100;

[0087] 7 parts of hydrogenated styrene isoprene copolymer;

[0088] 3.9 parts of ashless composite extreme pressure antiwear agent;

[0089] 1 part of multifunctional agent;

[0090] 9 parts of solid additives;

[0091] Among them, the lipophilic surface-modified nano-diamond dispersion is to uniformly disperse nano-diamonds with a particle size below 10nm in cyclohexane dicarboxylate, and disperse evenly through ultrasonic waves, and suspend within 2000h without precipitation. , the ratio of nano-diamon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com