Built-in bottom filling anti-overflow control device for canned oil tank

A control device and built-in technology, which is applied in the anti-overflow control of oil tank trucks and in the field of oil tank trucks, can solve problems such as roof spillage, environmental pollution, and impact on operation safety, and achieve high reliability and explosion-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0019] The technical scheme that the present invention solves the problems of the technologies described above is:

[0020] 1. Structural composition and working principle

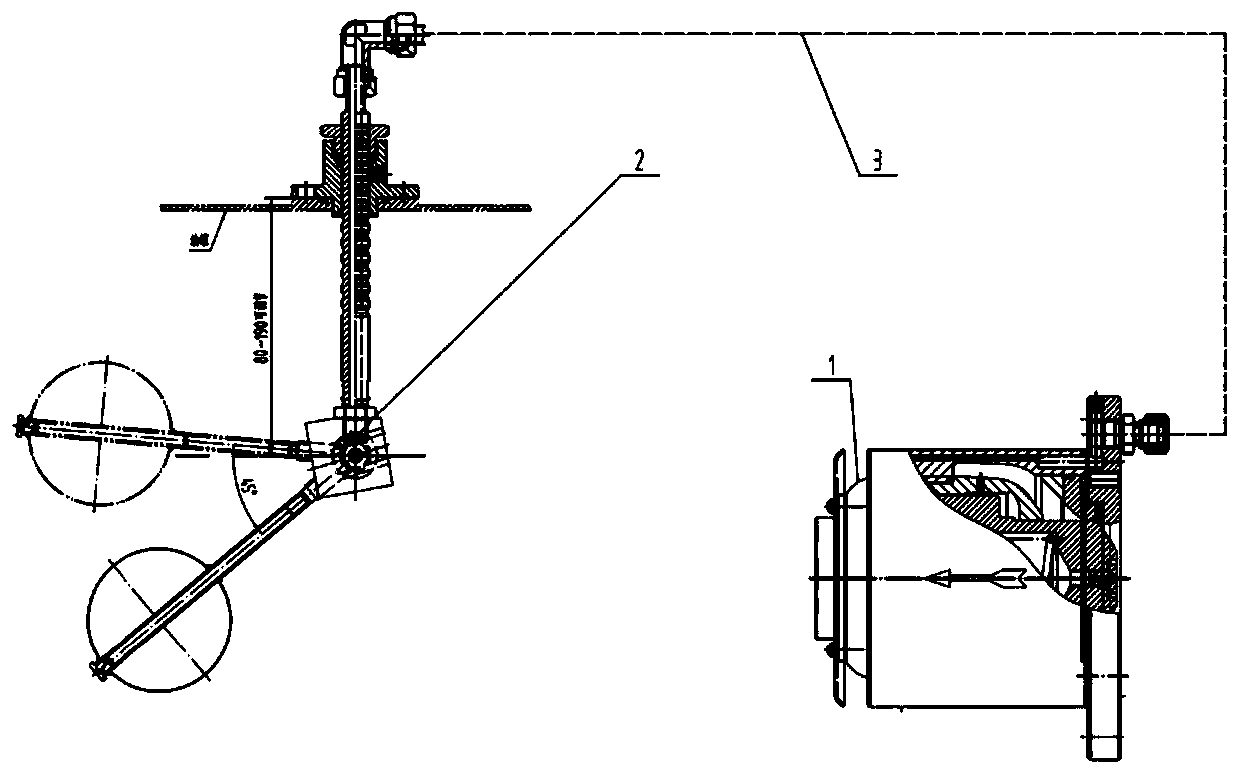

[0021] Bottom filling anti-overflow control device is composed of hydraulic control main valve, float pilot valve and connecting pipe, such as figure 1 shown. The hydraulic control main valve is installed in the oil tank of the inlet pipeline at the bottom of the oil tank, and the float pilot valve is installed on the top of the oil tank, and the float pilot valve communicates with the hydraulic control main valve through a connecting pipe.

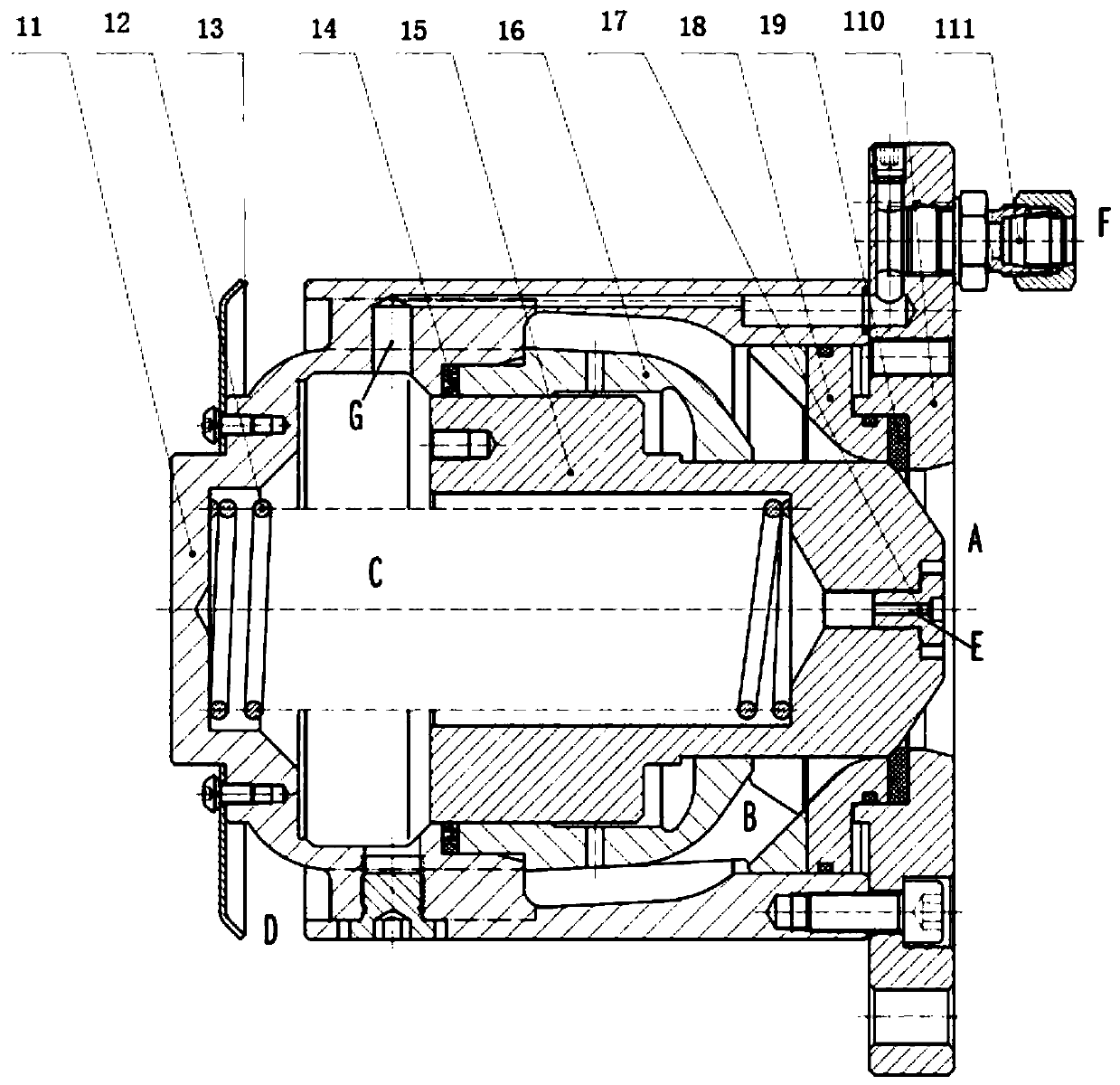

[0022] (1) Hydraulic control main valve

[0023] The hydraulic control main valve is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com