Polishing machine

A technology of polishing machine and moving mechanism, which is applied in the field of polishing machine, can solve the problems of slow polishing speed, unfavorable personal safety of workers, easy injury to hands, etc., and achieve the effect of protecting internal structure, improving flexibility and automation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

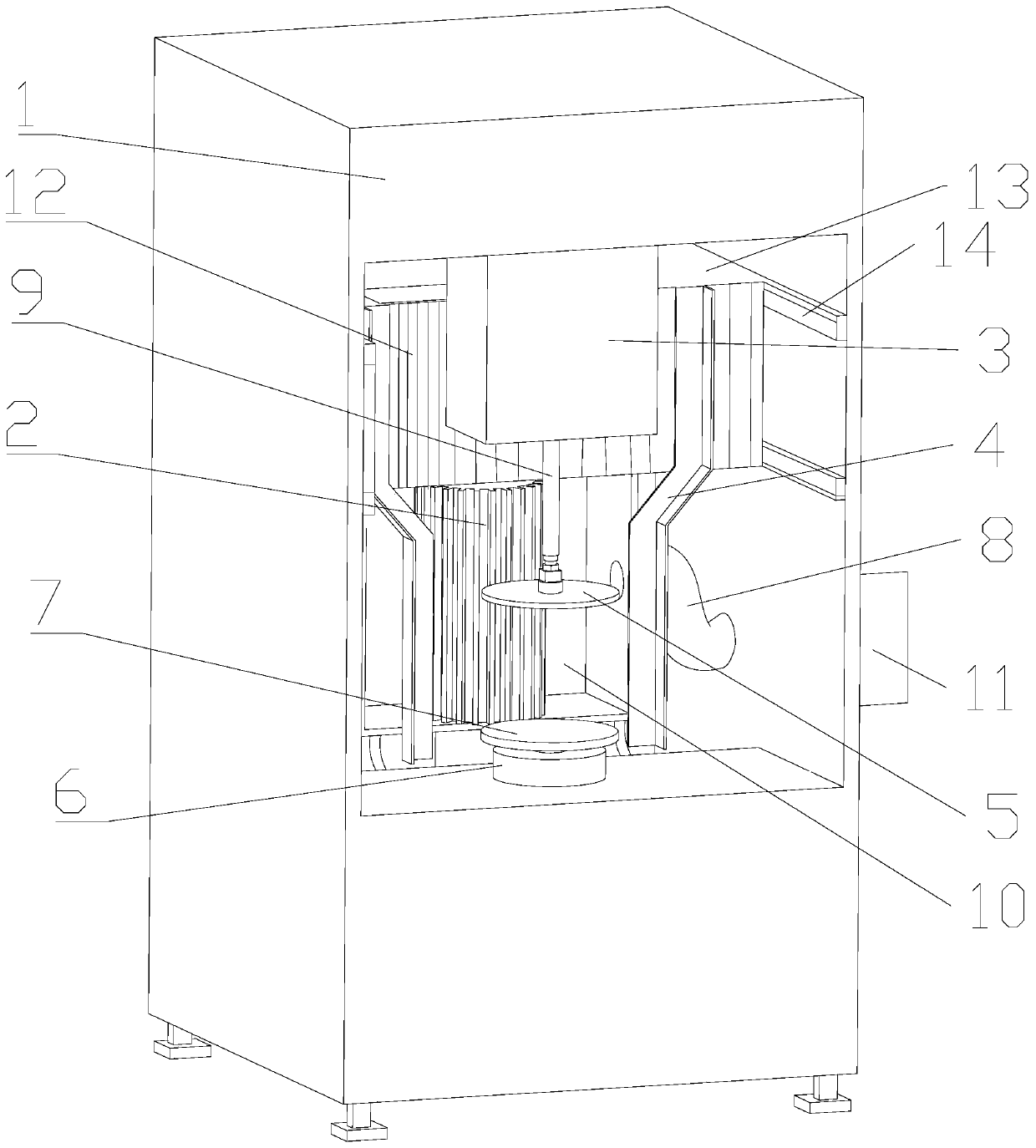

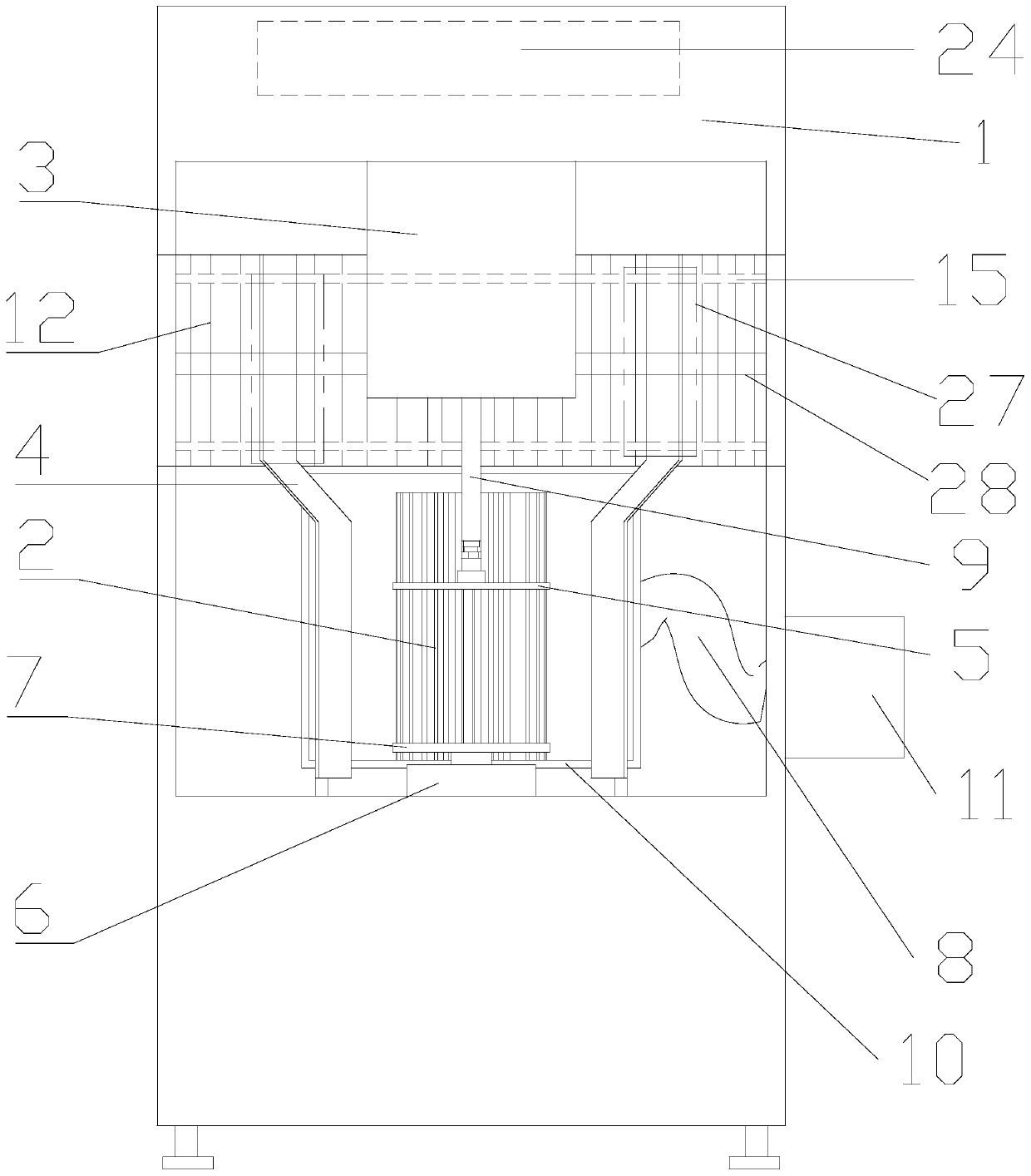

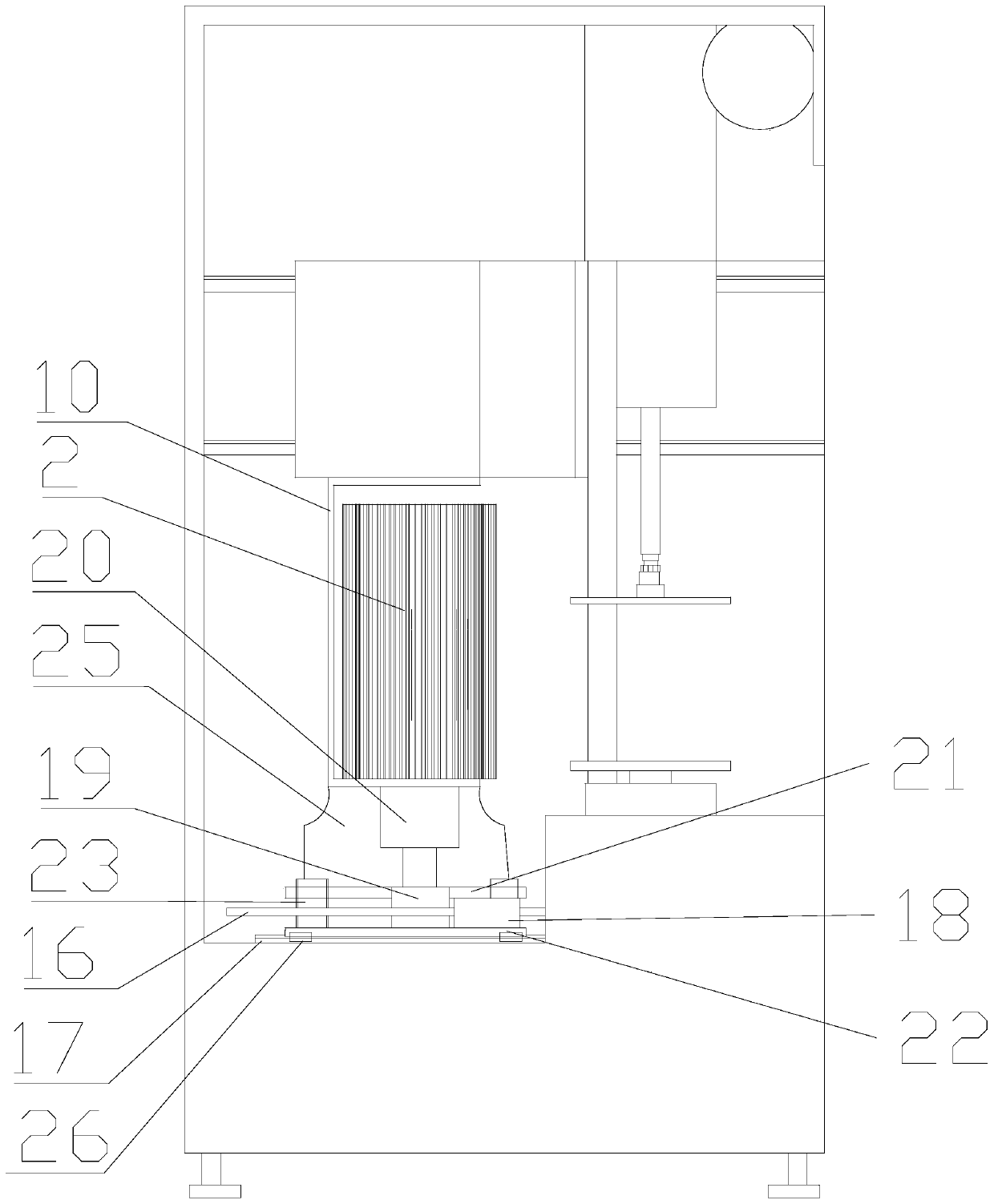

[0025] The invention discloses a polishing machine, which is used for grinding and polishing the corners of placemats. The polishing machine includes a polishing box 1, and the inner cavity of the polishing box 1 is provided with a cylinder 3, a positioning fixture table 13 and a polishing machine. Cavity 10, the bottom of the cylinder 3 is provided with a telescopic shaft 9, the telescopic shaft 9 is provided with a clamping panel 5, a tray 7 is provided below the corresponding position of the clamping panel 5, and a tray 7 is provided below the tray 7 Lifting platform 6 is arranged, and described positioning fixture platform 13 is equipped with moving mechanism, and what moving mechanism adopted promptly is screw drive, specifically comprises transverse guide rail 15, transverse screw mandrel 28, driving motor and traverse block 27, and transverse screw mandrel and The traversing block is slidably matched, and the driving motor is fixedly connected with the horizontal screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com