Rice shelling machine

A dehulling machine and rice technology, which is used in grain pod removal, grain hulling, and grain degermination, etc., can solve problems such as affecting the quality of rice, and achieve the effect of facilitating packaging or polishing treatment and saving water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

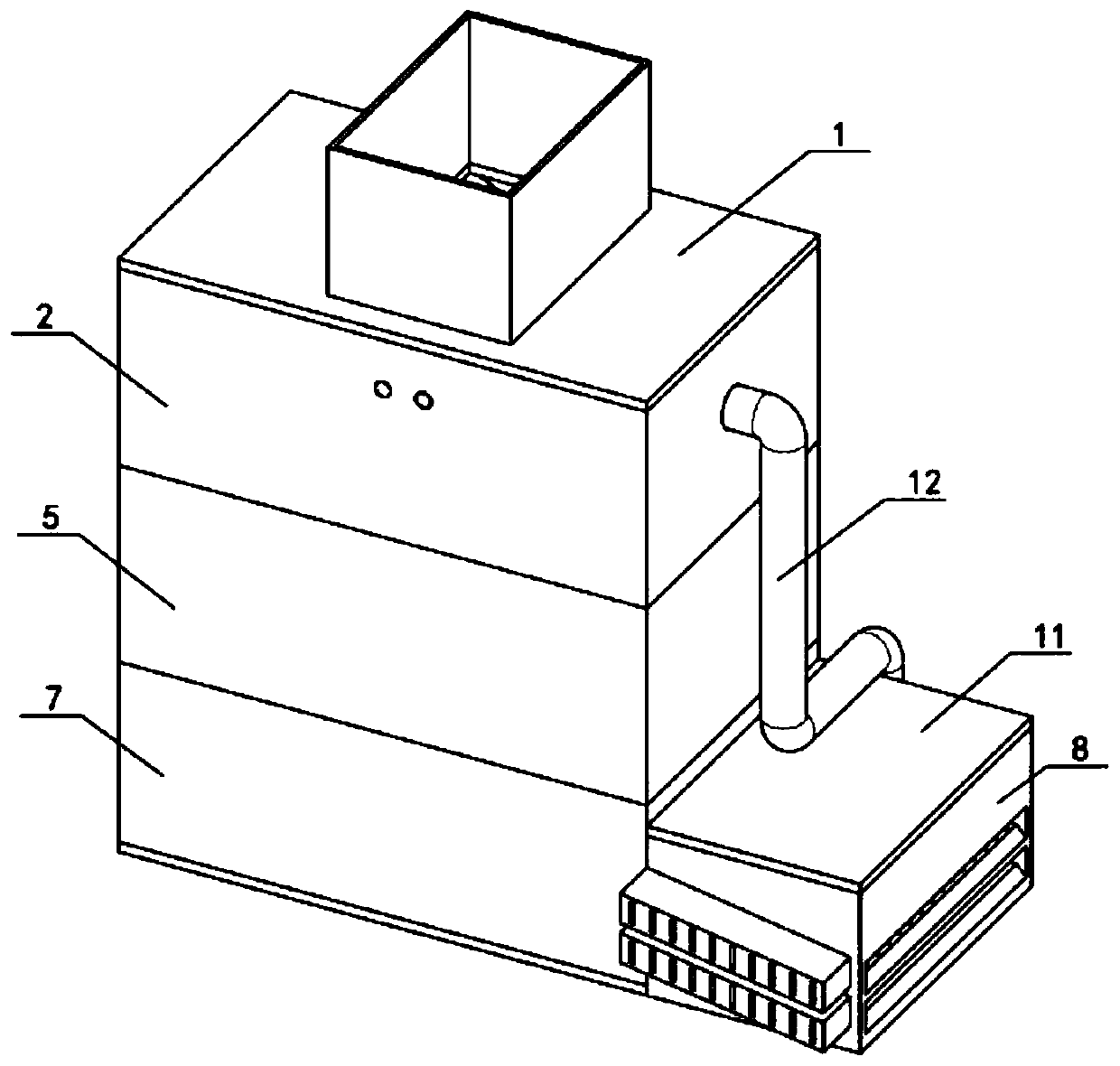

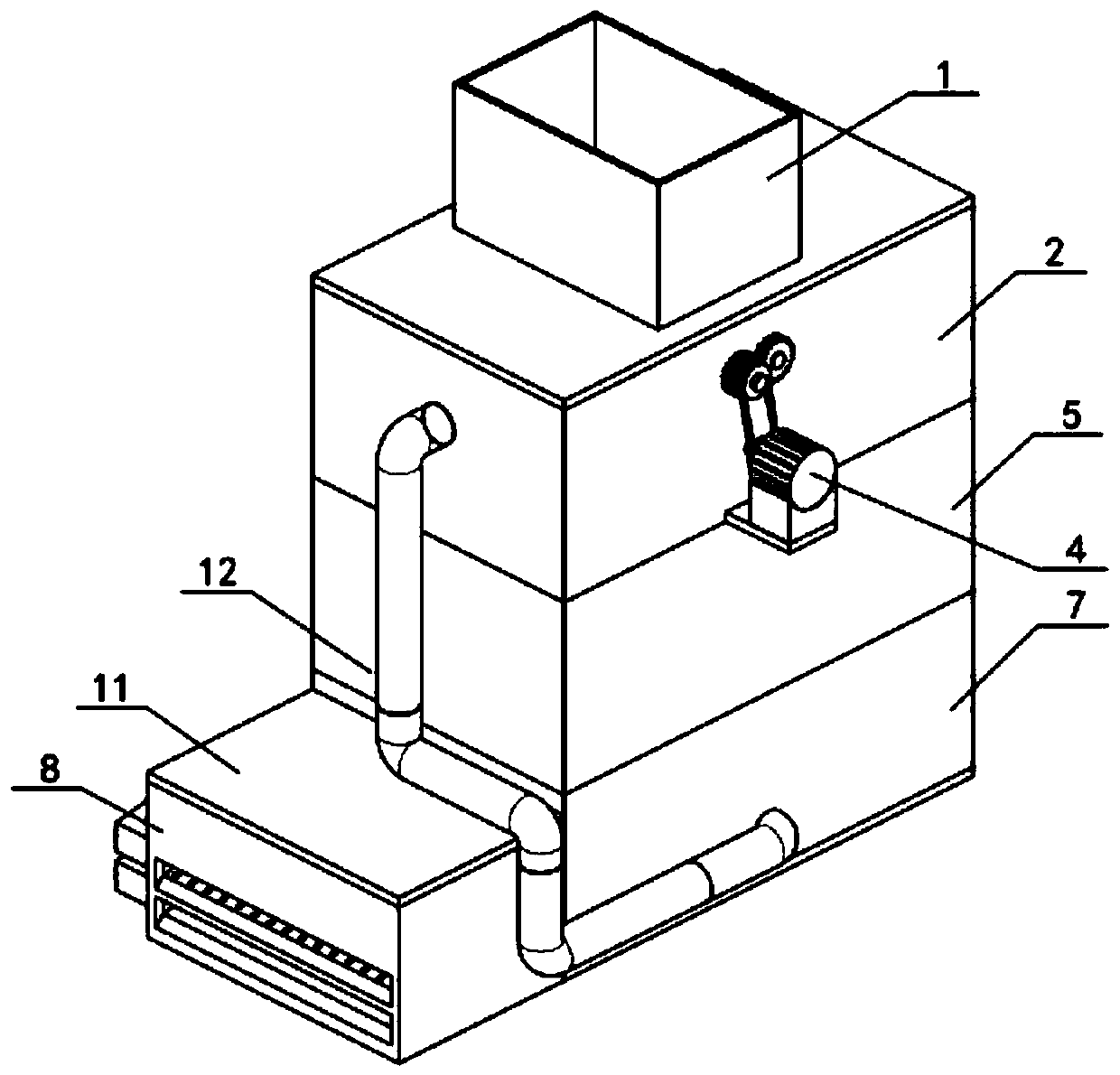

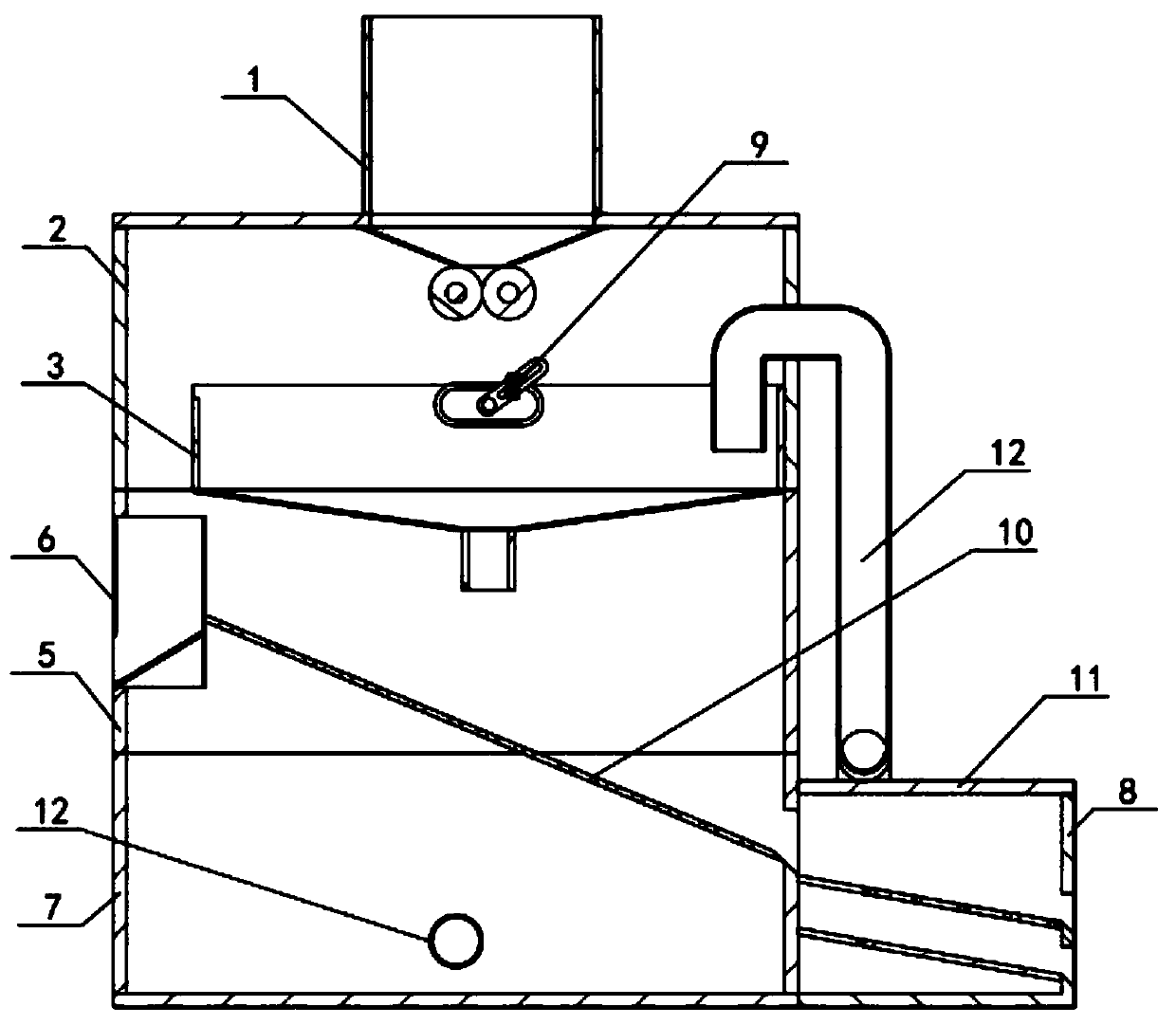

[0034] Such as Figure 1-13 Shown, a kind of rice shelling machine, comprises top box 1, upper box 2, separates built-in box 3, power part 4, middle box 5, dehydration casing box 6, lower box 7, dehydration screening box 8, pull out Plate 9, sliding plate 10, windshield 11 and water pipe 12, the upper end of the upper box 2 is fixedly connected to the top box 1, the separated built-in box 3 is fixedly connected to the right side of the inner end of the upper box 2, the power part 4 and the upper box 2 connection, the middle box 5 is fixedly connected to the lower end of the upper box 2, the dehydration shell discharge box 6 is slidably connected to the left end of the middle box 5, the lower box 7 is fixedly connected to the lower end of the middle box 5, and the dehydration screening box 8 and the lower box 7 The right end is fixedly connected, the pull-off plate 9 is fixedly connected with the separation built-in box 3, the left end of the sliding plate 10 is fixedly connect...

specific Embodiment approach 2

[0036] Such as Figure 1-13 As shown, the top box 1 includes a top plate 1-1, a material storage box 1-2 and a buffer funnel 1-3, the upper end of the top plate 1-1 is fixedly connected to the material storage box 1-2, and the buffer funnel 1-2 3 is fixedly connected to the lower end of the top plate 1-1, and the buffer funnel 1-3 is located directly below the material storage box 1-2. The function of the buffer funnel 1-3 is to make the rice accurately fall between the two rubber rollers 2-3 to prevent the rice from falling to other positions, and the storage box 1-2 is a container for storing the rice, and put the rice Storage boxes 1-2 get final product.

specific Embodiment approach 3

[0038] Such as Figure 1-13As shown, the upper case 2 includes an upper case body 2-1, a shaft 2-2, a rubber roller 2-3, a gear 2-4 and a pulley I2-5, and the upper case body 2-1 is rotatably connected to two A shaft 2-2, the middle parts of the two shafts 2-2 are respectively fixedly connected to a rubber roller 2-3, the two rubber rollers 2-3 are in contact, and the front ends of the two shafts 2-2 are respectively fixedly connected to a gear 2-4, The two gears 2-4 are meshed for transmission, and the pulley I2-5 is fixedly connected to the rear end of the shaft 2-2 at the right end; the upper box body 2-1 is fixedly connected to the lower end of the top plate 1-1, and the water pipe 12 The other end is fixedly connected and communicated with the right end of the upper box body 2-1, and the two rubber rollers 2-3 contacts are located directly below the buffer funnel 1-3. When the pulley I2-5 rotates, the pulley I2-5 drives the shaft 2-2 connected to it to rotate, the gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com