Microwave cooperative hot air drying method for green onion leaves

A technology of hot air drying and microwave drying, applied in the direction of dehydration preservation of fruits/vegetables, etc., can solve the problems of expensive drying equipment, long drying time, poor product quality, etc., to avoid a large amount of damage, extend the shelf life, and eat conveniently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Microwave synergistic hot air drying method of chive leaves

[0045] (1) Arranging raw materials

[0046] Get the fresh chives purchased in the market, remove the yellow leaves and rotten leaves and separate the leaves and petioles, and keep the leaves for later use.

[0047] (2) Cleaning and refreshing water

[0048] Wash the treated shallot leaves with flowing water, and place the washed leaves on a strainer to cool the water until there is no excess water on the surface.

[0049] (3) Cut into sections and shake water

[0050] Cut the shallot leaves after refreshing water into sections, the length of which is 8-10mm, and shake off the water for later use.

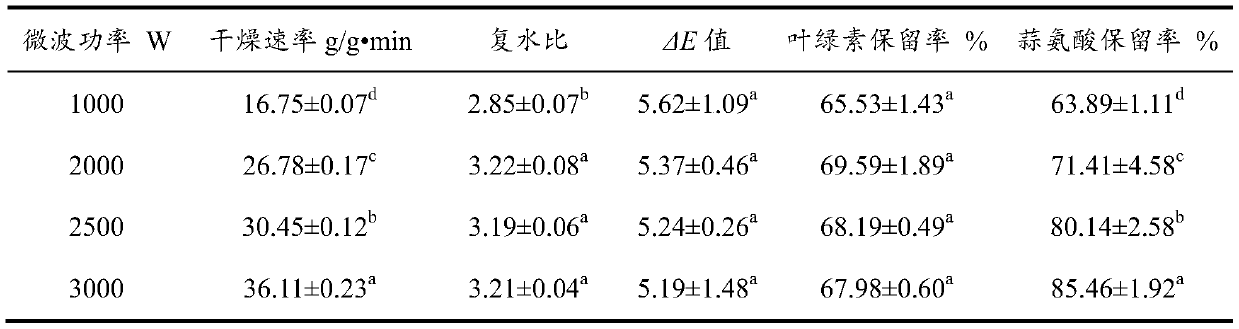

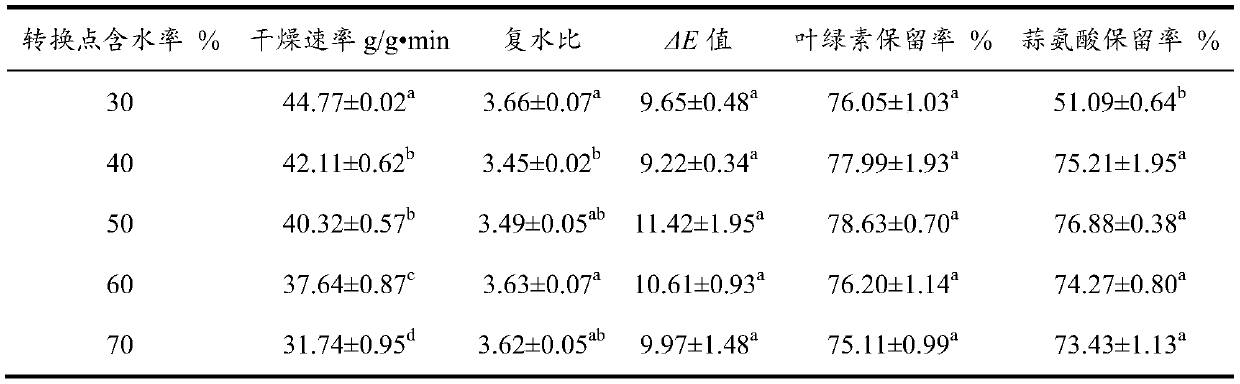

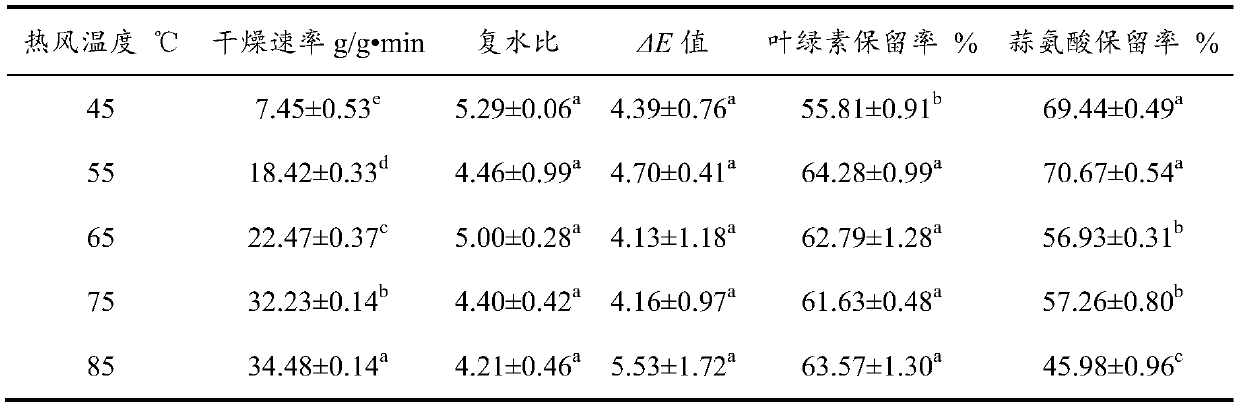

[0051] (4) Microwave pre-drying

[0052] Get 150g of sliced chive leaves and spread them evenly on the material conveyor belt of the tunnel microwave drying equipment, set the microwave power to 3000W, dry until the wet base moisture content of the chive blades is 50%, stop drying, and dry them ...

Embodiment 2

[0056] Embodiment 2: the microwave synergistic hot air drying method of chive leaves

[0057] (1) Arranging raw materials

[0058] Get the fresh chives purchased in the market, remove the yellow leaves and separate the leaves and petioles, and keep the leaves for later use.

[0059] (2) Cleaning and refreshing water

[0060] Wash the treated shallot leaves with flowing water, and place the washed leaves on a strainer to cool the water until there is no excess water on the surface.

[0061] (3) Cut into sections and shake water

[0062] Cut the shallot leaves after refreshing water into sections, the length of which is 8-10mm, and shake off the water for later use.

[0063] (4) Microwave pre-drying

[0064] Get 150g of sliced chive leaves and spread them evenly on the material conveyer belt of the tunnel microwave drying equipment, set the microwave power to 2000W, dry until the wet base moisture content of the chive blades is 50%, stop drying, and dry them Take it out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com