Method for manufacturing gold thread with no drawing-induced inconsistency, and gold thread manufactured by same

A manufacturing method and a non-uniform technology, applied in the field of gold wire manufacturing, can solve the problems of skin wrinkle removal and moisturizing effect and antibacterial effect, reduce production efficiency, and increase working time, etc., so as to promote cell regeneration and growth, improve Friction, the effect of improving bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to allow those with ordinary knowledge in the technical field of the present invention to easily implement the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention can be realized in various forms, and therefore should not be limited to the examples described here. The same symbols are assigned to similar parts throughout the specification.

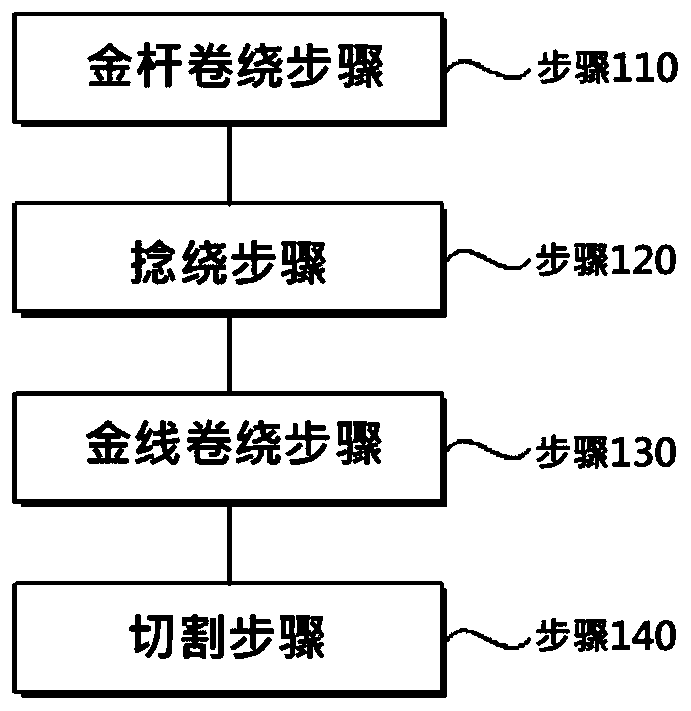

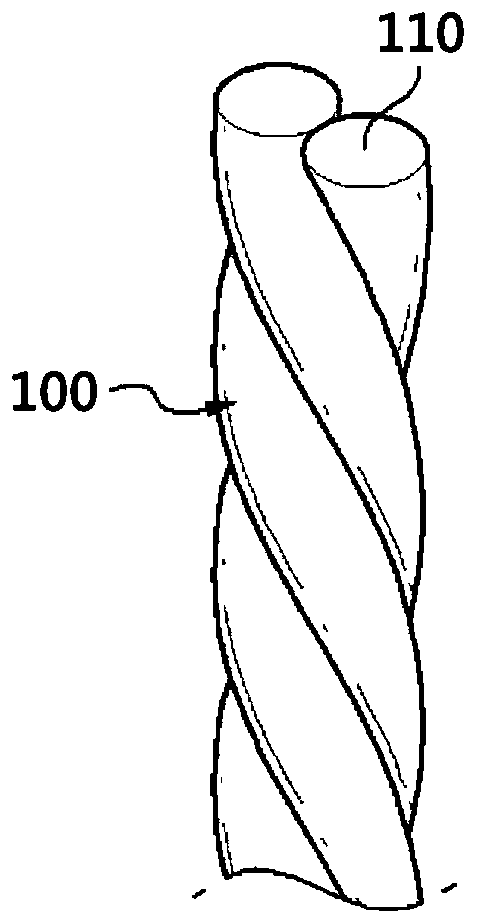

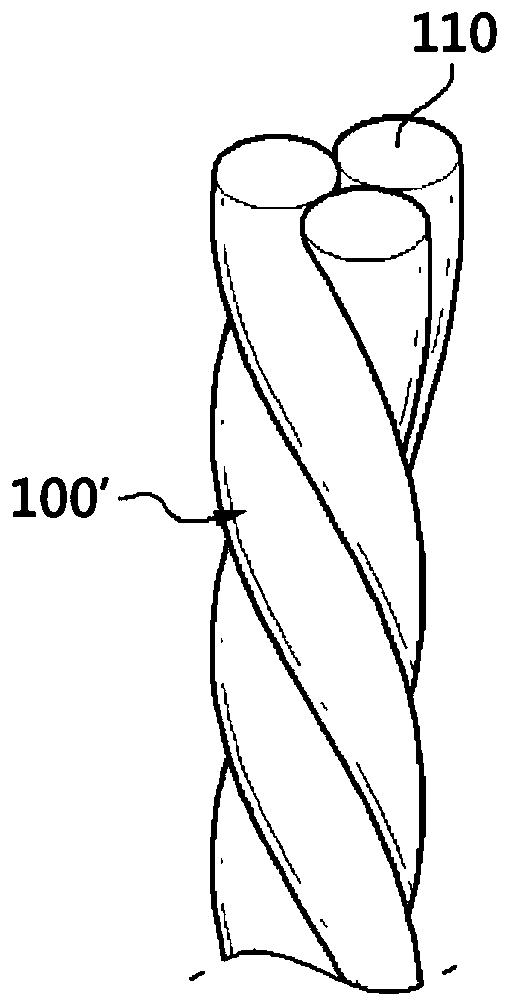

[0031] figure 1 is a flowchart schematically showing a gold wire manufacturing method according to an embodiment of the present invention, Figure 2 to Figure 3 is a perspective view of a gold wire showing an embodiment of the present invention.

[0032] see figure 1 , the manufacturing method of the gold wire that eliminates the non-uniformity caused by drawing according to an embodiment of the present invention includes a gold rod winding step (step 110) that draws a gold rod and winds it to a roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com