an air supply unit

A component and air supply technology, applied to pump components, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve problems such as occupying a large space, increase air flow, and facilitate drainage , the effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

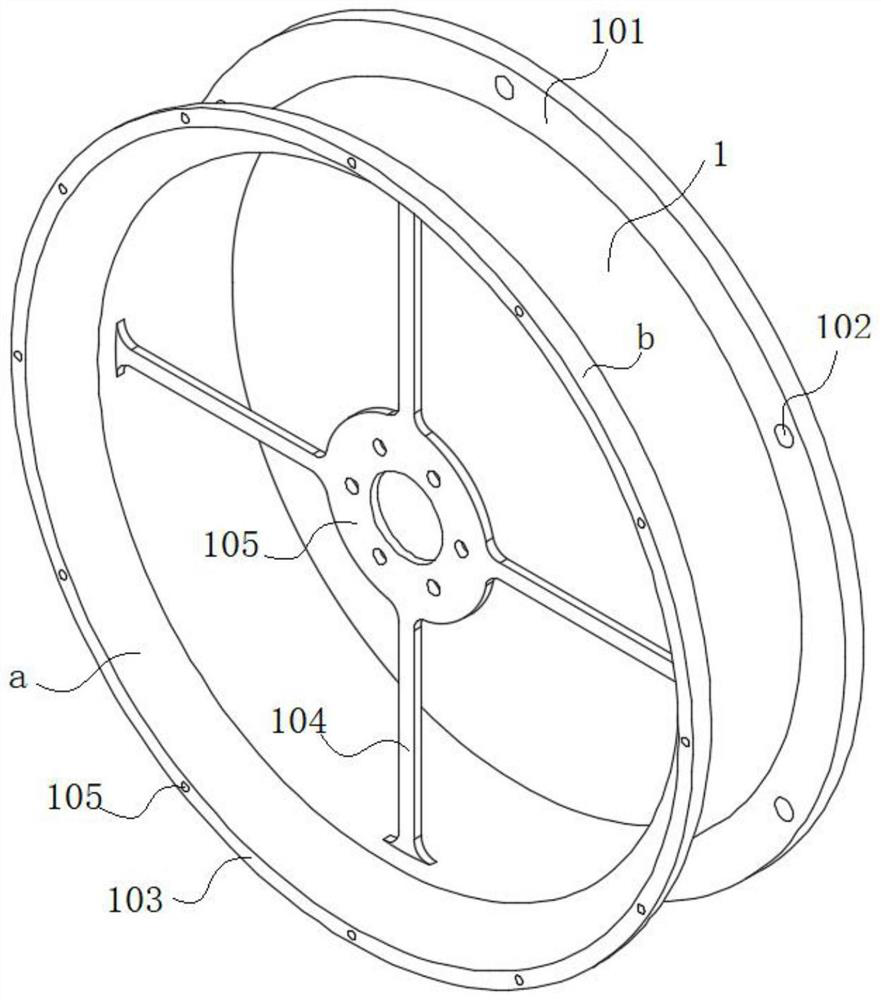

[0042]SeeFigure 1-2 As shown, the air supply assembly includes a first draft housing 1, a fan blade 5, a motor 4, a draft hood 3, and a second draft housing 2. The above-mentioned structural features constitute a basic structure. Both the first air induction shell 1 and the second air induction shell 2 are cylindrical structures.

[0043]SeeFigure 3-4 As shown, one end of the first air induction housing 1 is provided with a first arc-shaped cavity plate 103 extending outward. The first arc-shaped cavity plate 103 includes a first inner surface body a and a first outer surface body b; The end surface of the plate 103 is provided with an internal threaded hole 105; one end of the first draft housing 1 is also provided with a flange 101, and the end surface of the flange 101 is provided with a sealing groove 106 that cooperates with a sealing ring; A flange hole 102 is provided; the flange 101 at one end of the first air induction housing 1 can be used to cooperate with another air supply...

Embodiment 2

[0054]The overall structure is as shown in the first embodiment. In order to increase the wind power, another wind supply component can be superimposed. The basic stacking method is: based on the wind supply component shown in the first embodiment, add one end of the other wind supply component The draft hood 3 is removed, and at the same time, a flange is provided at one end of the second draft housing 2 for mating with the flange of the air supply assembly shown in the first embodiment, and more than one can be stacked in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com