Fabricated two-way steel bar truss floorslab

A technology of steel truss and two-way steel bars, which is applied to floors, building components, buildings, etc., can solve the problems of large amount of steel used for bottom chord steel bars and web steel bars, limited stress performance of triangular steel bar trusses, and inconvenient construction, and achieves a reduction in The effect of transportation cost, high assembly efficiency and simple shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A) Factory stage

[0050] Such as figure 1 As shown, the web steel bar 3 is prefabricated and welded at the contact point of the upper chord steel bar 1 and the lower chord steel bar 2, and the whole process is completed by automatic equipment. At both ends of the plane steel bar truss, a vertical support bar 4 is arranged, the upper part of the support bar 4 is aligned and welded with the end of the upper chord bar 1, the lower part of the support bar 4 is welded with the end of the lower chord bar 2, and the length of the lower end exceeds the lower chord bar 2 a certain distance. This creates a steel truss.

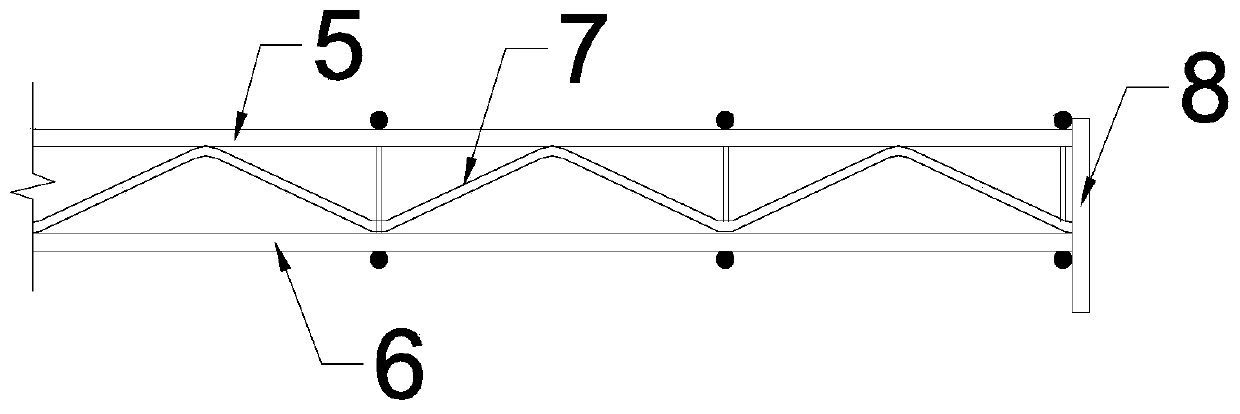

[0051] Such as Figure 6 As shown, a plurality of steel trusses are arranged in parallel to form a plane steel truss. After two sets of plane steel trusses are arranged in two directions, the upper chord steel bar 1 and the lower chord steel bar 2 of the steel bar truss in two directions are respectively welded and connected to form a well-shaped two-way stee...

Embodiment 2

[0059] A) Factory stage

[0060] Such as figure 1 As shown, the web steel bar 3 is prefabricated and welded at the contact point of the upper chord steel bar 1 and the lower chord steel bar 2, and the whole process is completed by automatic equipment. At both ends of the plane steel bar truss, a vertical support bar 4 is arranged, the upper part of the support bar 4 is aligned and welded with the end of the upper chord bar 1, the lower part of the support bar 4 is welded with the end of the lower chord bar 2, and the length of the lower end exceeds the lower chord bar 2 a certain distance. This creates a steel truss.

[0061] Such as Figure 6 As shown, a plurality of steel trusses are arranged in parallel to form a plane steel truss. After two sets of plane steel trusses are arranged in two directions, the upper chord steel bar 1 and the lower chord steel bar 2 of the steel bar truss in two directions are respectively welded and connected to form a well-shaped two-way stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com