Intensive pump house with lifting and water distributing functions

A lifting pump and water distribution technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems affecting the normal operation of sewage treatment plants, check valves or flapping doors are easily damaged, and the lifting pump room and water distribution well occupy a large area. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

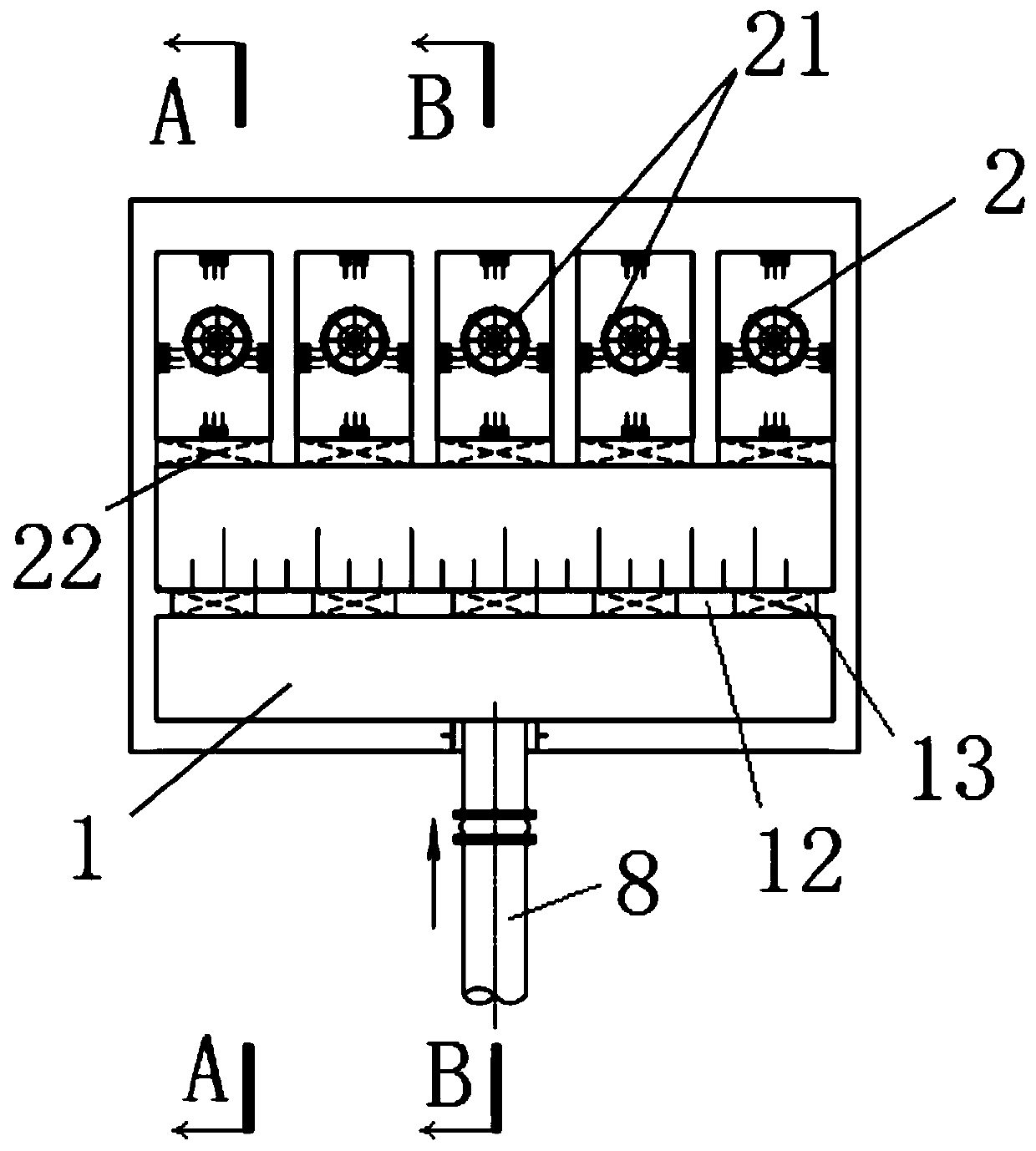

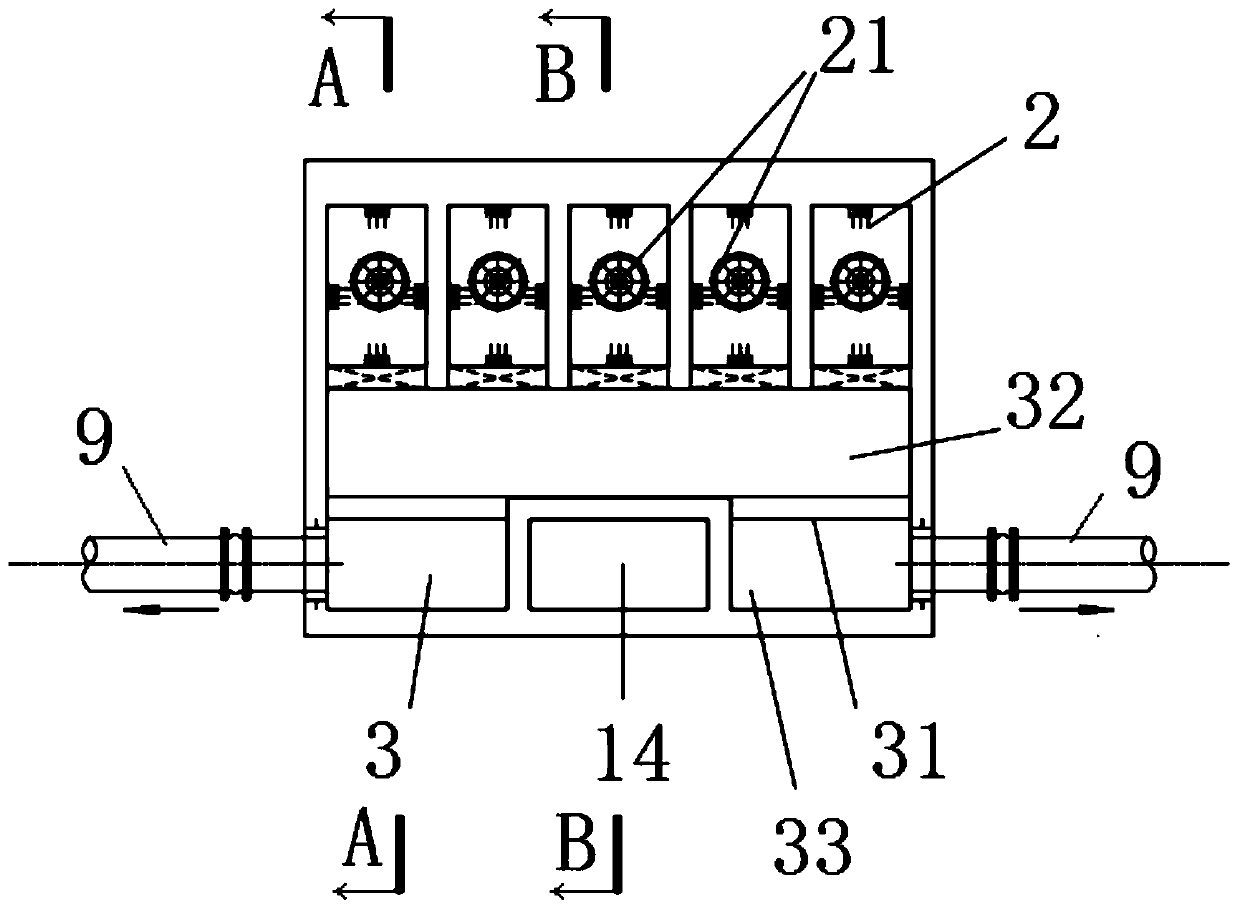

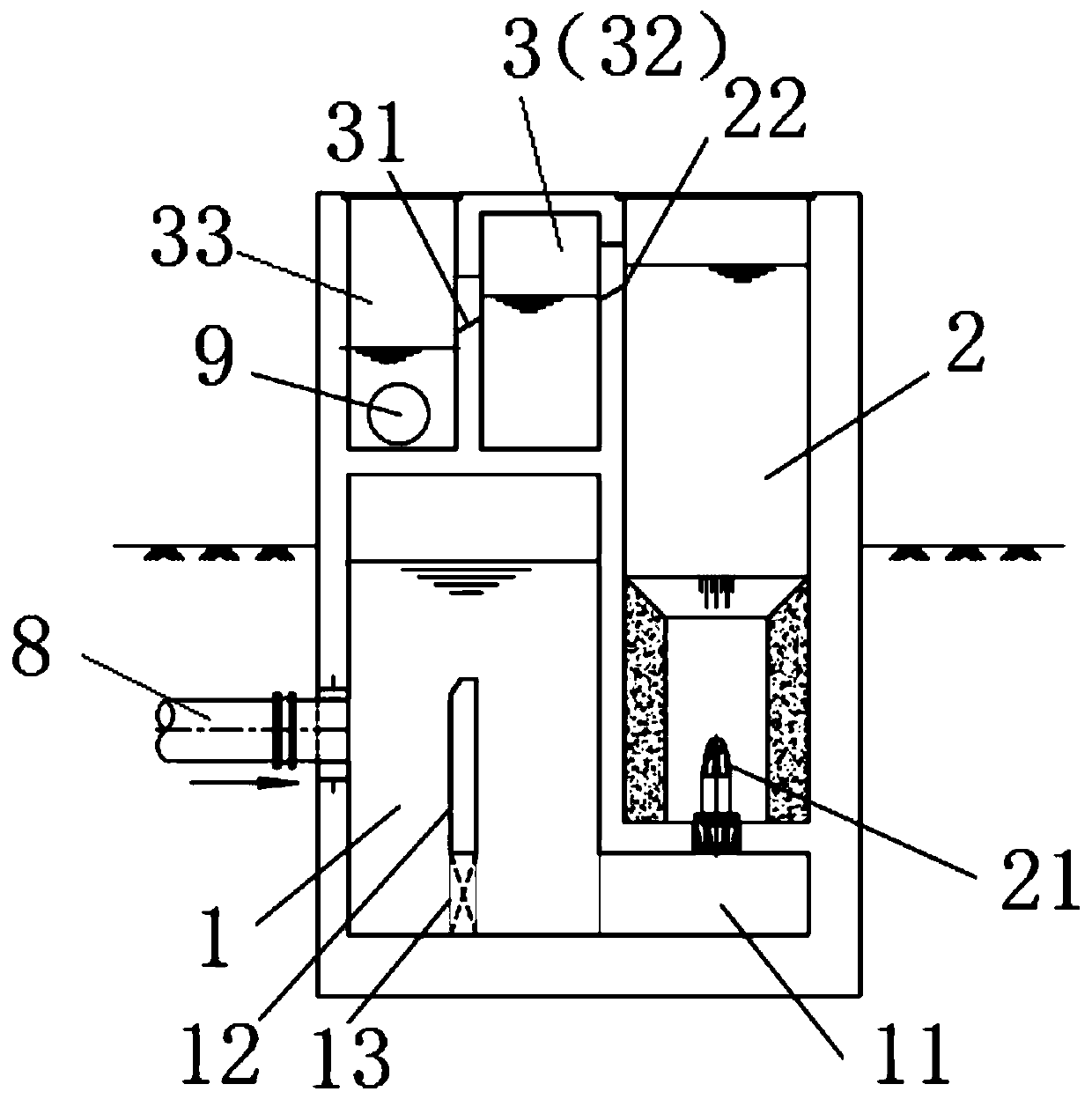

[0029] Such as Figure 1 to Figure 4 As shown, the intensive pump house with lifting and water distribution functions is used to lift the sewage treated by the secondary settling tank, including the water inlet area 1 connected to the water inlet pipe 8, and the sewage is obtained from the water inlet pipe 8, and the water outlet pipe 9 Connect, and discharge the water outlet area 3 of sewage by means of outlet pipe 9;

[0030] The water outlet area 3 is set directly above the water inlet area 1; the side of the water outlet area 3 and the water inlet area 1 is provided with a lifting area 2;

[0031] Several submersible lift pumps at the bottom of some water pump wells 21 at the lower part of the lifting area 2 pump the sewage in the water inlet area 1 to the lifting area 2, and raise the water level of the sewage in the lifting area 2, so that the sewage overflows to the water outlet area 3;

[0032] The water inlet of each submersible lift pump is connected with the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com