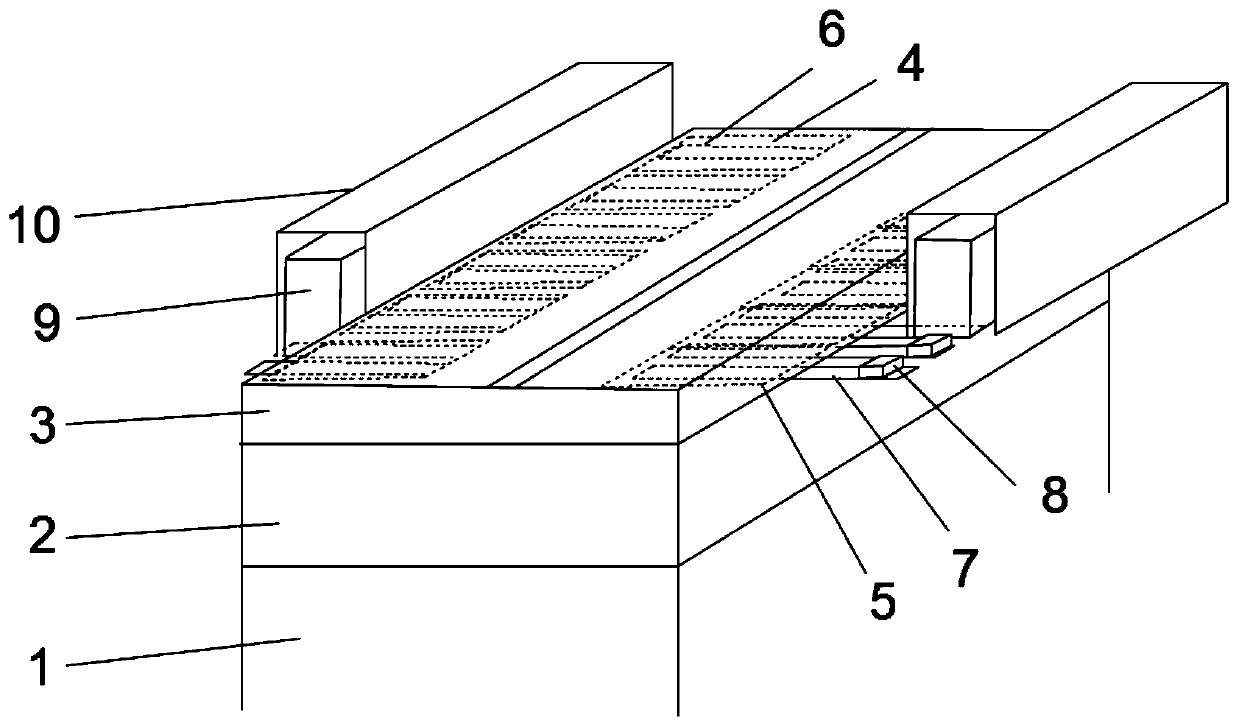

Thermoelectric power generation bituminous pavement structure and paving process thereof

A technology for asphalt pavement and thermoelectric power generation, which is applied to generators/motors, roads, roads, etc., and can solve the problems of prone to rutting, slippage, congestion, oil flooding, long duration of high temperature on the road, and the influence of urban heat and temperature systems. , to achieve the effect of alleviating high temperature disease of pavement, simple paving process and alleviating urban heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] First release the middle line and the first sideline of the pavement structure on the roadbed according to the site construction drawings, and release the second sideline 100mm away from the first sideline. The elevation is measured every 1000mm along the center of the road, and the elevation and cross slope of the road arch are every 15000mm. Set up a center pile; use lean concrete as the pavement base layer, carry out mixing, paving, and rolling molding, and groove and roughen the surface of the rigid base layer to keep the surface dry and clean; then prepare epoxy resin and epoxy asphalt ; After the preparation is completed, apply epoxy resin, calculate the amount of epoxy resin, control the epoxy resin coating thickness to 2mm, first brush the work surface with a brush for 3 times, and then use a brush for 2 times , The interval between each pass is 20 minutes; after epoxy resin coating for 30 minutes, pave the prefabricated building polyurethane thermal insulation sa...

Embodiment 2

[0100] First release the middle line and the first sideline of the pavement structure on the roadbed according to the site construction drawings, and release the second sideline 120mm outside the first sideline. The elevation is measured every 1000mm along the center of the road, and the elevation and cross slope of the road arch are every 15000mm. Set up a center pile; use cement concrete as the pavement base layer, carry out mixing, paving, and rolling molding, and groove and roughen the surface of the rigid base layer to keep the surface dry and clean; then prepare epoxy resin and epoxy asphalt ; After the preparation is completed, apply epoxy resin, calculate the amount of epoxy resin, control the epoxy resin coating thickness to 2mm, first brush the work surface with a brush for 3 times, and then use a brush for 2 times , The interval between each pass is 20 minutes; after epoxy resin coating for 30 minutes, pave the prefabricated building polyurethane thermal insulation sa...

Embodiment 3

[0103] First, release the middle line and the first sideline of the pavement structure on the roadbed according to the site construction drawings, and release the second sideline 100mm outside the first sideline. The elevation is measured every 1000mm along the center of the road, and the elevation and cross slope of the road arch are every 15000mm. Set up a center pile; use lean concrete as the pavement base layer, carry out mixing, paving, and rolling molding, and groove and roughen the surface of the rigid base layer to keep the surface dry and clean; then prepare epoxy resin and epoxy asphalt ; After the preparation is completed, apply epoxy resin, calculate the amount of epoxy resin, control the epoxy resin coating thickness to 2mm, first brush the work surface with a brush for 3 times, and then use a brush for 2 times , The interval between each pass is 20 minutes; 30 minutes after epoxy resin coating, pave the prefabricated building polyurethane thermal insulation sandwic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com