Production method of wool-like yarn

A production method and wool yarn technology are applied in the production field of wool-like yarn to achieve the effect of strong wool-like feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Taking the preparation of wool-like yarn with a linear density of 18.5tex as an example, the corresponding process parameters are as follows:

[0016] Raw material selection:

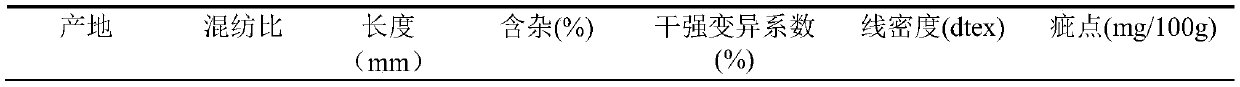

[0017] Table 1 Viscose

[0018]

[0019]

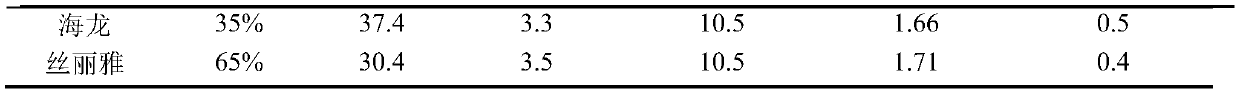

[0020] Table 2 Polyester

[0021]

[0022] Process flow:

[0023] Polyester: blowing carding → draw frame → roving → spun yarn → winding

[0024] Viscose: blowing carding → draw frame → roving → spun yarn → winding

[0025] Process parameter selection:

[0026] Table 3 Quantitative selection of products in each process

[0027]

[0028] Spinning Process Parameters

[0029] Table 4 Spinning process table

[0030]

[0031] Spinning frame process speed and ring design table

[0032]

[0033] Roving Process Parameters

[0034] Table 5 roving process table

[0035]

[0036] Roving frame other process design table

[0037]

[0038] Drawing frame parameters

[0039] Table 6 Drawing frame parameter design

[0040]

[0041] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com