Low-denier cotton-feeling filament yarn fabric and weaving method thereof

A filament fabric, cotton feeling technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of heavy cotton-like fabrics and weak cotton-like feeling, etc., to reduce drape, strong wool-like feeling, and increase warp tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and examples:

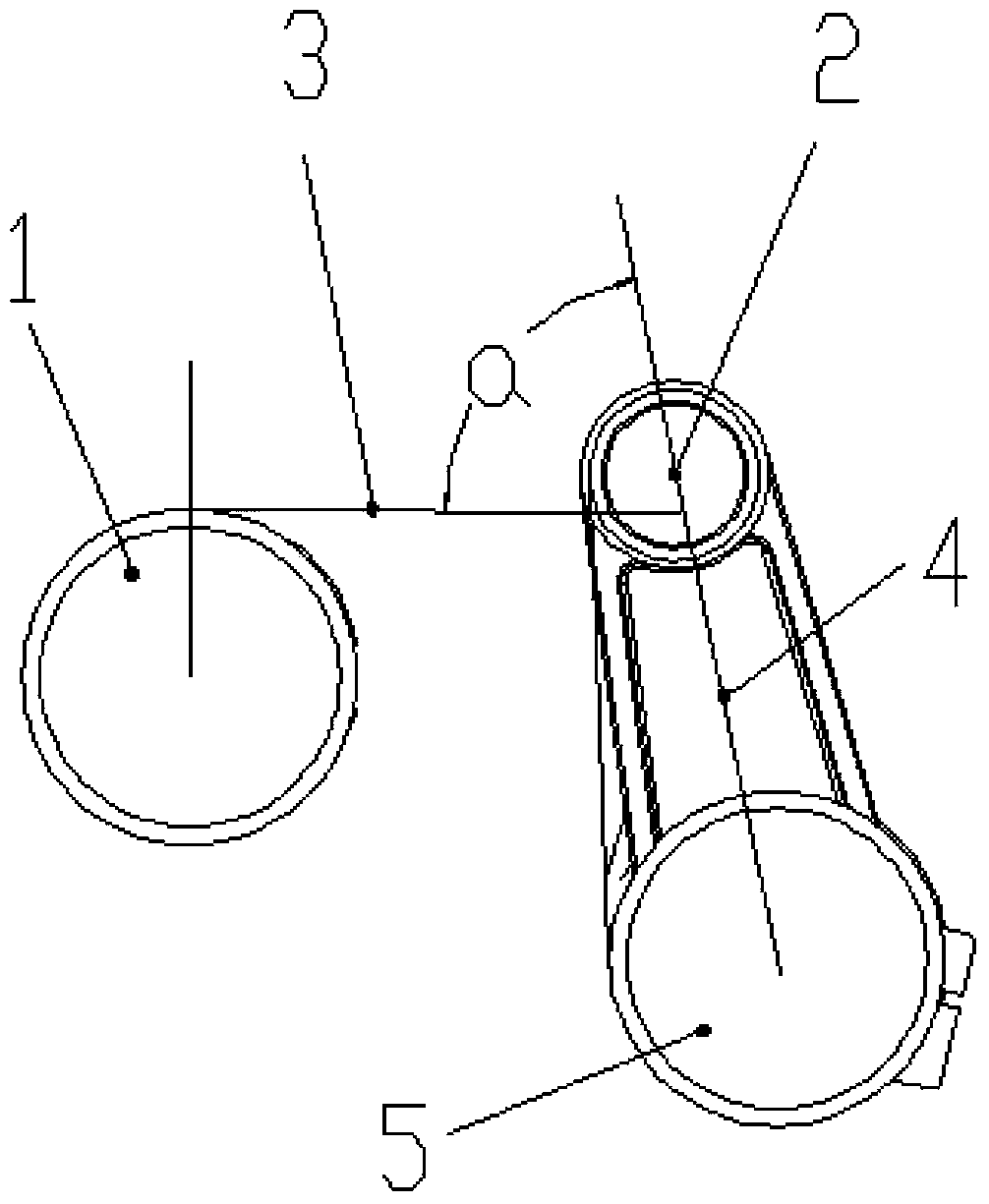

[0020] The fabric of the invention is characterized in that it fully utilizes the advantages of the good cotton-like feeling characteristics of the ATY air textured yarn to weave the cotton-like feeling fabric, and can process a low-denier cotton-like fabric.

[0021] The warp and weft of the fabric of the invention adopt ATY air textured low-denier yarns with a fineness of 30D-50D, which can make the fabric lighter, thinner, more comfortable, and have a strong cotton feel. Best, the fabric weight is 40-80g / m 2 .

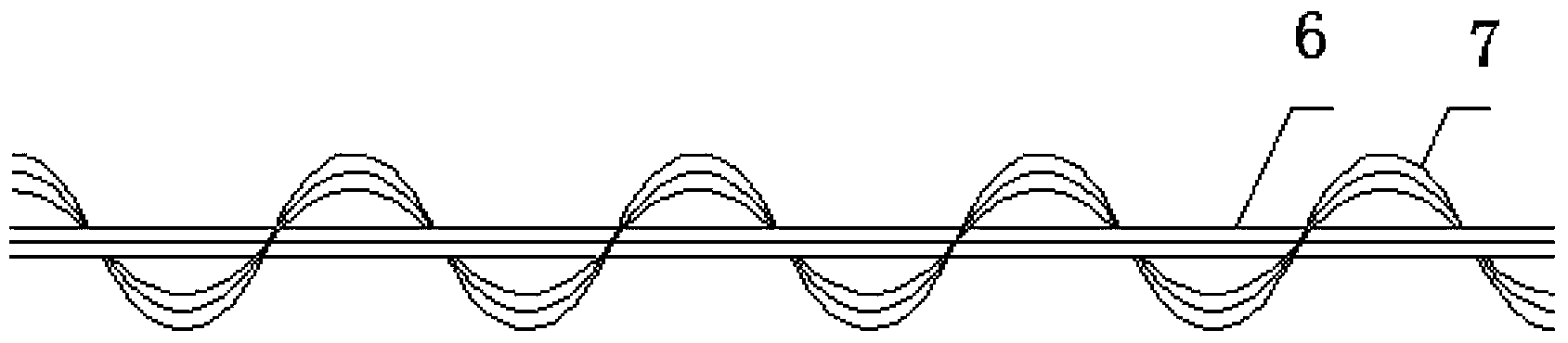

[0022] Compared with the conventional weaving process of cotton-like fabric, the fabric of the present invention has been improved in the following aspects: Because the warp yarn adopts ATY cotton-like yarn, such as figure 2 As shown, the yarn itself has a skin + core structure, that is, there is a skin yarn 7 wrapped around the core yarn 6, and the hairi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com