Laundry product with washing function and manufacturing method

A product and functional technology, applied in the field of laundry products and production with washing function, to achieve the effect of solving starch residue laundry equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

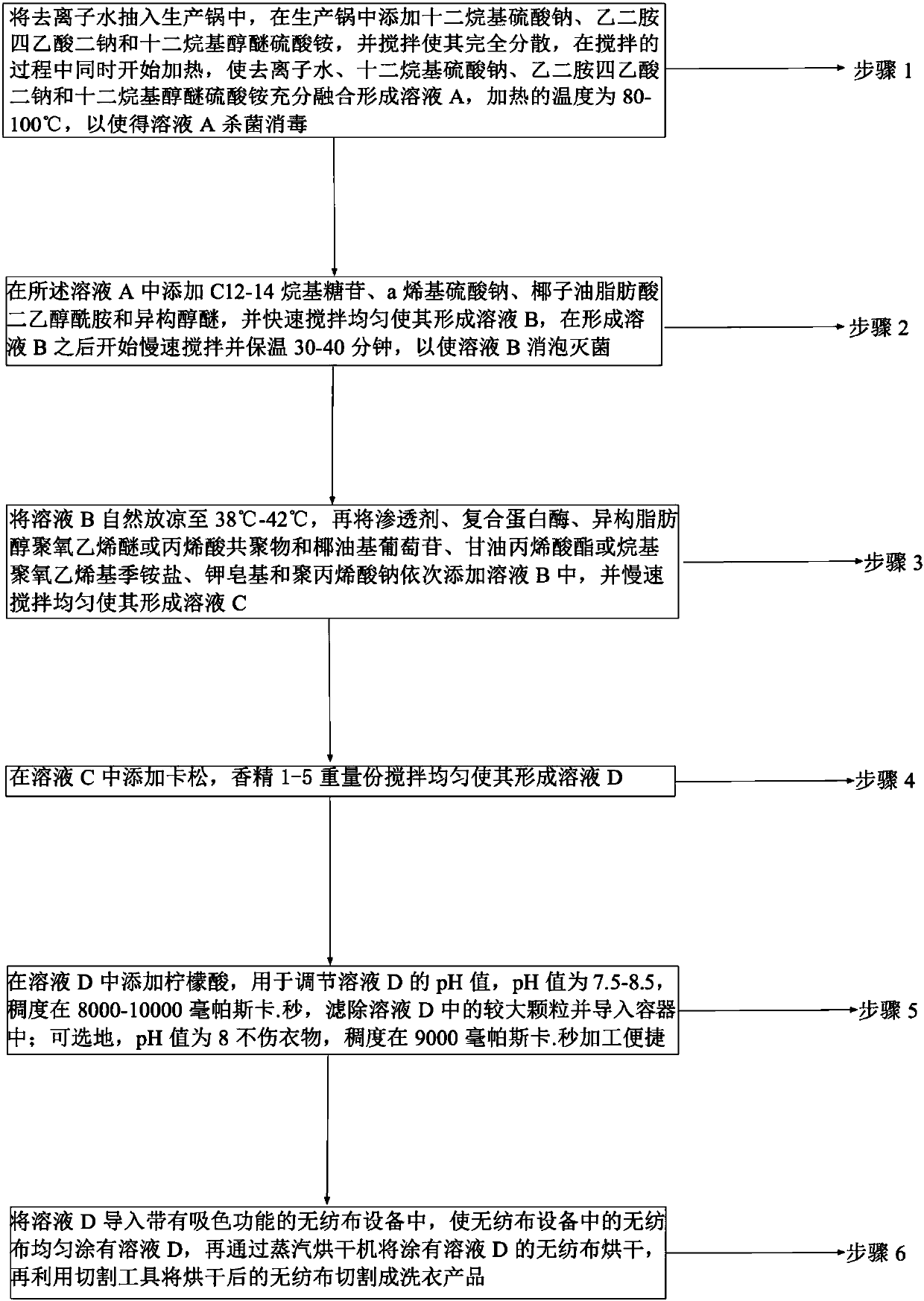

Method used

Image

Examples

Embodiment 1

[0033] A laundry product with washing function, the laundry product includes the following components: the first component or the second component: 3-15 parts by weight; wherein, the first component includes isomerized fatty alcohol polyoxyethylene ether and glycerin acrylate The second component includes acrylic acid copolymer, coconut oil glucoside and alkyl polyoxyethylene quaternary ammonium salt; penetrant: 0.5-7 parts by weight; deionized water: 35-60 parts by weight; composite protease: 0.8- 3 parts by weight.

[0034] By using the first component or the second component in combination with the penetrating agent and the compound protease, the washing effect is improved while solving the problem of starch residue laundry equipment.

[0035] In this embodiment, the first component or the second component: 5-13 parts by weight; penetrant: 1.5-5.5 parts by weight; deionized water: 40-55 parts by weight; composite protease: 1-2.8 parts by weight, Further improve the washing...

Embodiment 2

[0037] Laundry products with washing function, including: first component or second component: 3-15 parts by weight; wherein, the first component includes isomerized fatty alcohol polyoxyethylene ether and glycerin acrylate; the second component includes Acrylic acid copolymer, cocoyl glucoside and alkyl polyoxyethylene quaternary ammonium salt; penetrant: 0.5-7 parts by weight; composite protease: 0.8-3 parts by weight; sodium lauryl sulfate: 3-16 parts by weight .

[0038] By adding sodium lauryl sulfate, it has decontamination, emulsification and excellent foaming power, has anionic surfactant, and biodegradability >90%.

[0039] In this embodiment, optionally, the first component or the second component: 8 parts by weight; wherein, the first component includes isomeric fatty alcohol polyoxyethylene ether and glycerin acrylate; the second component includes acrylic acid Copolymer, cocoyl glucoside and alkyl polyoxyethylene quaternary ammonium salt; penetrant: 3 parts by we...

Embodiment 3

[0042] Laundry products with washing function, including: first component or second component: 3-15 parts by weight; wherein, the first component includes isomerized fatty alcohol polyoxyethylene ether and glycerin acrylate; the second component includes Acrylic acid copolymer, cocoyl glucoside and alkyl polyoxyethylene quaternary ammonium salt; penetrant: 0.5-7 parts by weight; composite protease: 0.8-3 parts by weight; disodium edetate: 0.08-0.8 parts by weight Parts; Lauryl ether ammonium sulfate: 10-22 parts by weight.

[0043]In this embodiment, optionally, the first component or the second component: 8 parts by weight; wherein, the first component includes isomeric fatty alcohol polyoxyethylene ether and glycerin acrylate; the second component includes acrylic acid Copolymer and cocoyl glucoside and alkyl polyoxyethylene quaternary ammonium salt; penetrant: 3 parts by weight; complex protease: 2 parts by weight; disodium edetate: 0.5 parts by weight; lauryl alcohol Ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com