Method for producing organic fertilizer from municipal sludge

A technology of municipal sludge and organic fertilizer, applied in the preparation of organic fertilizer, organic fertilizer, sewage/sludge fertilizer, etc., can solve the problems of affecting the quality of organic fertilizer and reducing the dehydration rate, and promote the process of aerobic composting of sludge. , Improve the blocking problem, improve the effect of microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

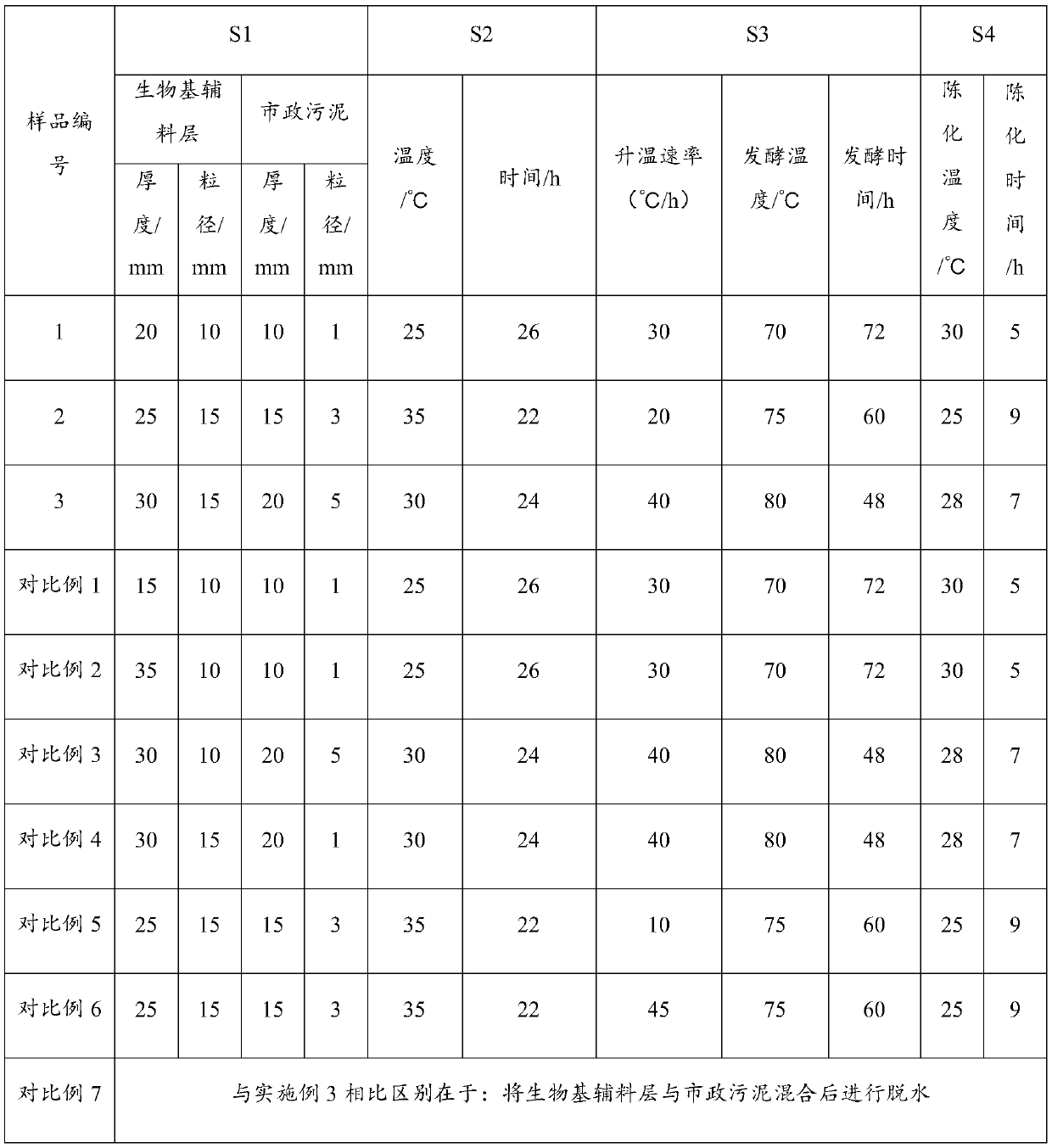

[0024] Embodiment 1: a kind of method utilizing municipal sludge to produce organic fertilizer:

[0025] S1: Dehydration of mixed materials:

[0026] First lay a layer of bio-based auxiliary material with a thickness of 20-30mm on the filter cloth, lay a layer of municipal sludge with a thickness of 10-20mm on the bio-based auxiliary material layer, and then lay a layer of 20-30mm on the municipal sludge layer. The thickness of the bio-based auxiliary material layer is carried out by the high-efficiency filter press dehydration method in the patent document CN103553294B for the pressing and dehydration process;

[0027] S2: Pre-fermentation process:

[0028] The process of pre-fermenting the mixed material after S1 dehydration into the buffer silo, the pre-fermentation temperature of the mixed material during the pre-fermentation is 25-35°C, and the pre-fermentation time is 22-26h;

[0029] S3: Fermentation process:

[0030] Loading the pre-fermented mixture of S2 into ferm...

Embodiment 2

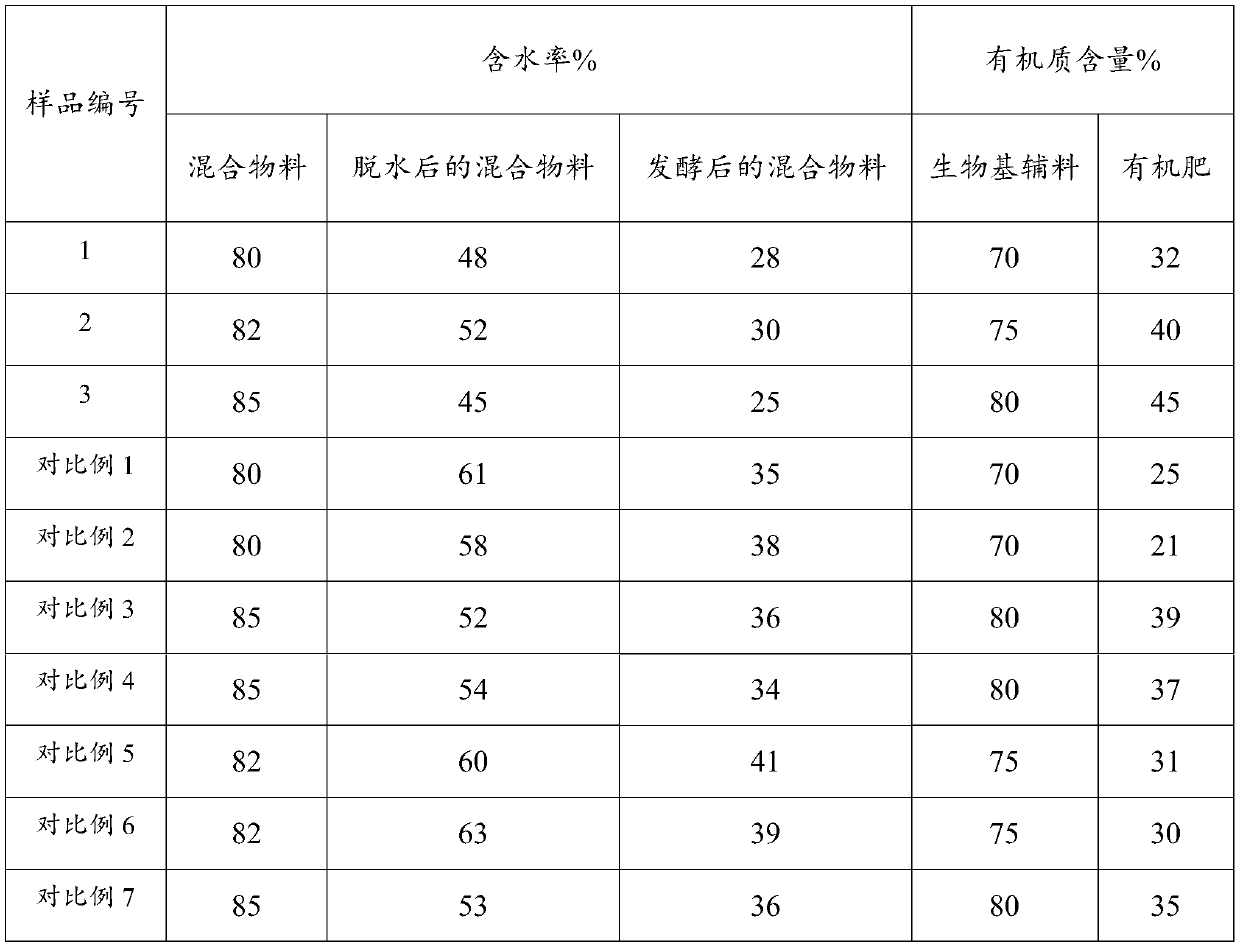

[0040] Example 2: Characterization

[0041] Table 2 organic fertilizer performance test results

[0042]

[0043] From the experimental results in Table 2, it can be seen that water can dissolve organic matter in the process of microbial reproduction, promote its metabolism, and adjust the temperature of the heap by evaporating water. If there is too much moisture, the pores of the material in the pile are small, which will affect the exchange of oxygen with the outside world, resulting in an anaerobic environment and a foul smell; if the moisture content is too low, it will affect the growth and reproduction of microorganisms, and also delay the composting process. Composting results have a big impact.

[0044] If the particle size of the material is smaller, the specific surface area of the reactor body is larger, and the reaction proceeds faster. However, if the particle size is too small, it will hinder the ventilation and oxygen supply of the stack. If the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com